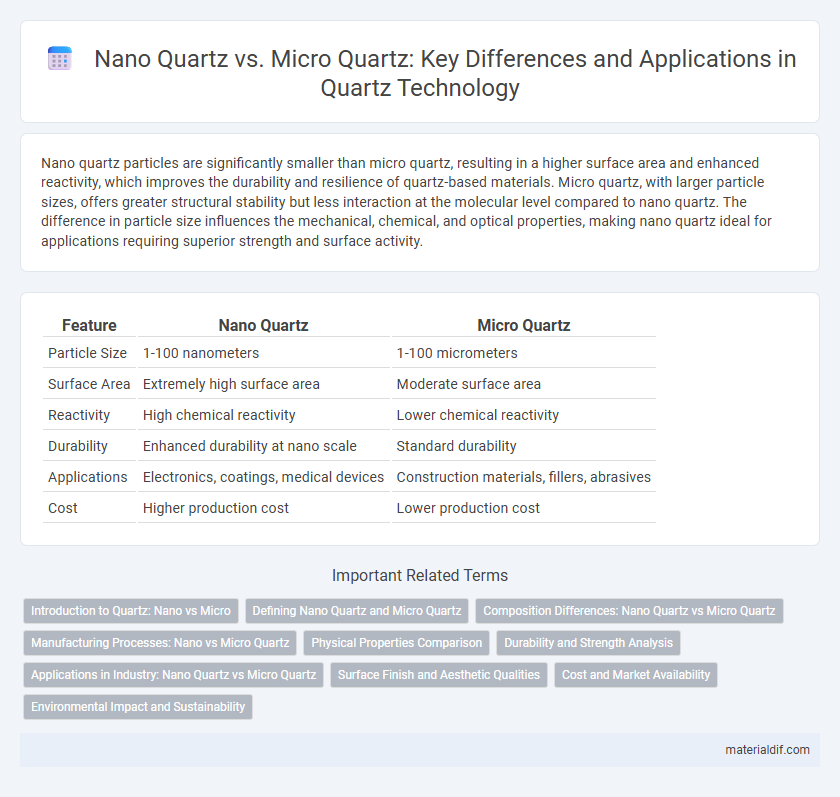

Nano quartz particles are significantly smaller than micro quartz, resulting in a higher surface area and enhanced reactivity, which improves the durability and resilience of quartz-based materials. Micro quartz, with larger particle sizes, offers greater structural stability but less interaction at the molecular level compared to nano quartz. The difference in particle size influences the mechanical, chemical, and optical properties, making nano quartz ideal for applications requiring superior strength and surface activity.

Table of Comparison

| Feature | Nano Quartz | Micro Quartz |

|---|---|---|

| Particle Size | 1-100 nanometers | 1-100 micrometers |

| Surface Area | Extremely high surface area | Moderate surface area |

| Reactivity | High chemical reactivity | Lower chemical reactivity |

| Durability | Enhanced durability at nano scale | Standard durability |

| Applications | Electronics, coatings, medical devices | Construction materials, fillers, abrasives |

| Cost | Higher production cost | Lower production cost |

Introduction to Quartz: Nano vs Micro

Quartz exists in various forms, with nano quartz particles measuring less than 100 nanometers and micro quartz particles ranging from 1 to 100 micrometers. Nano quartz exhibits a larger surface area to volume ratio, enhancing its reactivity and applications in high-precision technologies, whereas micro quartz is commonly used in industrial processes and construction materials due to its stability and ease of handling. Understanding the differences between nano and micro quartz is essential for selecting the appropriate type for applications like electronics, coatings, or composites.

Defining Nano Quartz and Micro Quartz

Nano Quartz refers to quartz particles with sizes typically below 100 nanometers, exhibiting enhanced surface area and unique physical properties compared to larger particles. Micro Quartz consists of quartz particles ranging from 1 to 100 micrometers, commonly used in various industrial applications for its durability and chemical stability. The distinction between Nano and Micro Quartz lies primarily in particle size, influencing their respective reactivity, optical properties, and potential uses in advanced materials and coatings.

Composition Differences: Nano Quartz vs Micro Quartz

Nano quartz particles measure less than 100 nanometers, featuring a higher surface area to volume ratio compared to micro quartz particles, which range from 1 to 100 micrometers. The increased reactivity of nano quartz is attributed to its atomic-scale surface structure, enabling enhanced interaction with bonding agents in composite materials. Micro quartz, with larger particle size, exhibits lower surface chemistry complexity and reduced reactivity, making it suitable for applications requiring mechanical durability rather than surface functionalization.

Manufacturing Processes: Nano vs Micro Quartz

Nano quartz manufacturing involves advanced techniques such as sol-gel processing or hydrothermal synthesis to produce ultra-fine particles with sizes typically below 100 nanometers, resulting in higher surface area and enhanced reactivity. Micro quartz is commonly produced through mechanical milling or controlled precipitation methods, yielding particles in the micrometer range, which offer distinct structural properties suitable for traditional applications. The precision in nano quartz synthesis allows for tailored functionalities in electronics and optics, whereas micro quartz remains essential for broader industrial uses due to its ease of production and cost-effectiveness.

Physical Properties Comparison

Nano quartz particles typically exhibit higher surface area and enhanced mechanical strength compared to micro quartz due to their reduced size, which results in increased reactivity and improved bonding within composite materials. Micro quartz grains, generally ranging from 1 to 100 micrometers, provide greater abrasion resistance and thermal stability, making them suitable for applications requiring durability under mechanical stress. The distinct differences in particle size influence thermal conductivity, hardness, and fracture toughness, with nano quartz offering superior performance in nanocomposite technologies while micro quartz remains optimal for traditional industrial uses.

Durability and Strength Analysis

Nano quartz exhibits superior durability compared to micro quartz due to its finer particle size, which enhances structural integrity and reduces porosity. The uniformity of nano quartz particles results in improved mechanical strength, making it more resistant to fractures and wear. Micro quartz, while durable, lacks the enhanced toughness and resilience provided by the nanostructured composition.

Applications in Industry: Nano Quartz vs Micro Quartz

Nano quartz particles exhibit superior surface area and reactivity compared to micro quartz, making them ideal for advanced coatings, electronics, and catalysis applications. Micro quartz, with its larger particle size, is commonly used in traditional industries such as construction, glass manufacturing, and abrasives, providing mechanical strength and durability. The distinct properties of nano and micro quartz determine their suitability across various industrial sectors, optimizing performance based on particle scale.

Surface Finish and Aesthetic Qualities

Nano Quartz offers a superior surface finish compared to Micro Quartz due to its finer particle size, resulting in a smoother and more uniform texture that enhances the overall aesthetic appeal. The smaller nanoparticles in Nano Quartz enable higher translucency and brilliance, providing a polished look with fewer visible imperfections. In contrast, Micro Quartz tends to have a rougher surface with less light reflection, making it less ideal for applications where refined visual quality is critical.

Cost and Market Availability

Nano quartz particles typically cost more than micro quartz due to advanced manufacturing techniques and enhanced performance properties. Micro quartz remains more widely available in the market, favored for its cost-effectiveness and suitability for large-scale industrial applications. The price difference influences buyer preference, with nano quartz preferred in high-end, specialized uses despite limited supply compared to bulk micro quartz.

Environmental Impact and Sustainability

Nano quartz particles exhibit a significantly higher surface area-to-volume ratio compared to micro quartz, potentially increasing their reactivity and environmental persistence. The production of nano quartz often requires more energy-intensive processes, contributing to a larger carbon footprint than micro quartz manufacturing. However, both forms must be carefully managed to mitigate inhalation risks and prevent environmental contamination, emphasizing the need for sustainable handling and disposal practices.

Nano Quartz vs Micro Quartz Infographic

materialdif.com

materialdif.com