Fused quartz and fused silica are both forms of high-purity silicon dioxide but differ primarily in their production methods and resulting properties. Fused quartz is made by melting natural quartz crystals, offering exceptional thermal stability and resistance to chemical corrosion, making it ideal for high-temperature applications. Fused silica, produced from synthetic silicon dioxide, provides superior optical clarity and lower thermal expansion, which is crucial for precision optics and semiconductor manufacturing.

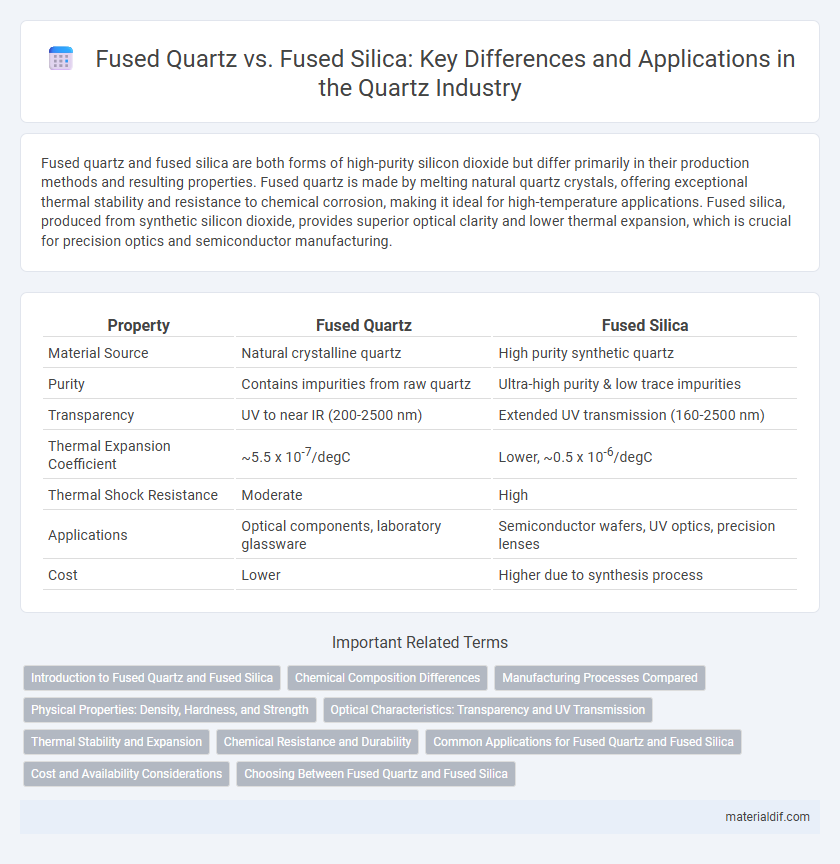

Table of Comparison

| Property | Fused Quartz | Fused Silica |

|---|---|---|

| Material Source | Natural crystalline quartz | High purity synthetic quartz |

| Purity | Contains impurities from raw quartz | Ultra-high purity & low trace impurities |

| Transparency | UV to near IR (200-2500 nm) | Extended UV transmission (160-2500 nm) |

| Thermal Expansion Coefficient | ~5.5 x 10-7/degC | Lower, ~0.5 x 10-6/degC |

| Thermal Shock Resistance | Moderate | High |

| Applications | Optical components, laboratory glassware | Semiconductor wafers, UV optics, precision lenses |

| Cost | Lower | Higher due to synthesis process |

Introduction to Fused Quartz and Fused Silica

Fused quartz and fused silica are both high-purity forms of silicon dioxide used in advanced optical and industrial applications due to their exceptional thermal stability and low thermal expansion. Fused quartz is manufactured by melting high-purity natural quartz crystals, resulting in a glass with high optical clarity and resistance to thermal shock. Fused silica, produced from synthetic silicon tetrachloride or quartz sand through vapor deposition, offers superior purity and reduced hydroxyl content, making it ideal for ultraviolet optics and semiconductor processes.

Chemical Composition Differences

Fused quartz is composed almost entirely of pure silicon dioxide (SiO2) with a very low level of impurities, typically exceeding 99.9% purity. Fused silica, although also primarily SiO2, is produced from synthetic silica rather than natural quartz, resulting in a more uniform chemical composition with fewer trace elements. These differences in chemical purity directly impact thermal stability, optical clarity, and mechanical properties, making fused silica preferable for high-precision applications.

Manufacturing Processes Compared

Fused quartz is produced by melting high-purity natural quartz crystals, resulting in a material with low hydroxyl content and high thermal stability, while fused silica is manufactured by melting synthetic silicon dioxide via flame hydrolysis, yielding higher purity and superior ultraviolet transparency. The flame fusion process of fused silica enables better control over chemical composition and reduces impurities, making it ideal for semiconductor and optical fiber applications. In contrast, fused quartz's natural sourcing leads to slightly variable properties, often used where mechanical strength and thermal shock resistance are prioritized.

Physical Properties: Density, Hardness, and Strength

Fused quartz and fused silica both exhibit high purity and excellent thermal stability, but fused silica typically has a slightly lower density around 2.21 g/cm3 compared to quartz's 2.65 g/cm3. In terms of hardness, fused quartz rates approximately 7 on the Mohs scale, offering superior scratch resistance relative to fused silica, which tends to be slightly softer. Strength-wise, fused silica excels with higher tensile strength and better resistance to thermal shock, making it preferable in high-stress optical and industrial applications.

Optical Characteristics: Transparency and UV Transmission

Fused quartz and fused silica both exhibit exceptional transparency in the ultraviolet (UV) spectrum, with fused silica offering slightly higher UV transmission, making it ideal for high-precision optical applications. Fused quartz typically contains more impurities, which can reduce its UV transparency compared to the ultra-pure nature of fused silica. The superior optical clarity and minimal absorption of fused silica enable enhanced performance in UV lasers and semiconductor photolithography.

Thermal Stability and Expansion

Fused quartz and fused silica both exhibit exceptional thermal stability, but fused quartz typically has a higher purity level, reducing thermal expansion to approximately 0.5 x 10^-6 /degC. Fused silica features an ultra-low thermal expansion coefficient near 0.55 x 10^-6 /degC, enhancing its resistance to thermal shock and dimensional changes under extreme temperature fluctuations. These properties make fused silica ideal for precision optical components and high-temperature industrial applications requiring minimal thermal deformation.

Chemical Resistance and Durability

Fused quartz and fused silica both exhibit exceptional chemical resistance, making them ideal for use in harsh chemical environments where contamination and degradation must be minimized. Fused silica offers superior durability due to its lower impurity levels and higher purity, resulting in enhanced thermal and mechanical stability under extreme conditions. These characteristics make fused silica the preferred material for applications requiring long-term resistance to corrosive substances and structural integrity.

Common Applications for Fused Quartz and Fused Silica

Fused quartz and fused silica are widely used in high-precision optical applications, such as lenses, prisms, and windows, due to their exceptional transparency to ultraviolet and infrared light. Fused quartz is commonly employed in semiconductor manufacturing and UV lithography because of its high purity and low thermal expansion. Fused silica finds extensive use in fiber optics, laser systems, and aerospace components where high thermal stability and resistance to thermal shock are critical.

Cost and Availability Considerations

Fused quartz and fused silica differ significantly in cost and availability, with fused quartz generally being more expensive due to higher purity and controlled manufacturing processes. Fused silica, typically produced from natural quartz sand, is more widely available and cost-effective for large-scale industrial applications. Selection between these materials often hinges on budget constraints and the specific purity requirements of the intended use.

Choosing Between Fused Quartz and Fused Silica

Choosing between fused quartz and fused silica depends on application-specific requirements such as thermal stability, purity, and cost. Fused silica offers higher purity and superior thermal shock resistance, making it ideal for precision optics and semiconductor manufacturing. Fused quartz, while less pure and more cost-effective, is suitable for general-purpose uses where extreme temperature or purity is not critical.

Fused Quartz vs Fused Silica Infographic

materialdif.com

materialdif.com