Man-made quartz, also known as engineered or synthetic quartz, is composed of approximately 90% natural quartz combined with resins and pigments to enhance durability and aesthetic variety, making it ideal for countertops and decorative surfaces. Pure quartz is a natural mineral formed through geological processes, prized for its hardness, clarity, and use in electronics, glassmaking, and industrial applications where chemical purity and structural integrity are crucial. Understanding the distinction between man-made and pure quartz helps consumers and industries select the appropriate material for specific functional and visual requirements.

Table of Comparison

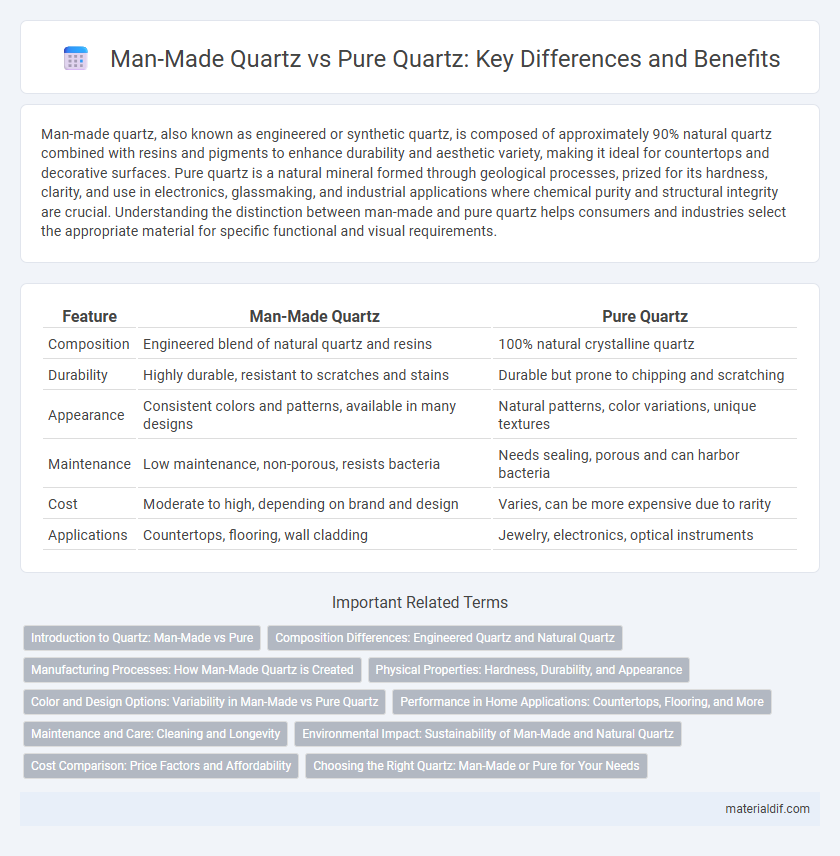

| Feature | Man-Made Quartz | Pure Quartz |

|---|---|---|

| Composition | Engineered blend of natural quartz and resins | 100% natural crystalline quartz |

| Durability | Highly durable, resistant to scratches and stains | Durable but prone to chipping and scratching |

| Appearance | Consistent colors and patterns, available in many designs | Natural patterns, color variations, unique textures |

| Maintenance | Low maintenance, non-porous, resists bacteria | Needs sealing, porous and can harbor bacteria |

| Cost | Moderate to high, depending on brand and design | Varies, can be more expensive due to rarity |

| Applications | Countertops, flooring, wall cladding | Jewelry, electronics, optical instruments |

Introduction to Quartz: Man-Made vs Pure

Quartz is a widely used mineral found both naturally and in synthetic forms, with pure quartz consisting of silicon dioxide in its crystalline structure. Man-made quartz, often referred to as engineered quartz, combines crushed natural quartz with resins and pigments to create durable, non-porous surfaces for countertops and other applications. The key difference lies in composition and consistency; pure quartz is mined and cut, while man-made quartz offers enhanced strength, uniform appearance, and customizable colors for various design needs.

Composition Differences: Engineered Quartz and Natural Quartz

Engineered quartz combines natural quartz crystals with resins and pigments, creating a non-porous, durable surface ideal for countertops, while pure quartz consists of nearly 100% silicon dioxide formed naturally over millions of years. The synthetic resin binder in man-made quartz enhances flexibility and stain resistance, contrasting with natural quartz's inherent brittleness and variable mineral inclusions. This composition difference influences maintenance requirements and aesthetic consistency, making engineered quartz versatile for modern interior design.

Manufacturing Processes: How Man-Made Quartz is Created

Man-made quartz is produced through a complex manufacturing process involving the blending of natural quartz crystals with resins and pigments, followed by compression and curing under high pressure and temperature to form durable engineered slabs. This technique enables precise control over color, texture, and durability, offering consistency not found in pure quartz, which is naturally occurring and harvested from quarries. The engineered composition of man-made quartz makes it highly resistant to stains, scratches, and heat, ideal for countertops and architectural surfaces.

Physical Properties: Hardness, Durability, and Appearance

Man-made quartz exhibits a hardness of approximately 7 on the Mohs scale, closely matching the natural quartz's hardness, which ranges from 7 to 7.5, ensuring both materials offer excellent scratch resistance. In terms of durability, man-made quartz is engineered with resins that enhance its resistance to staining and impact, often surpassing pure quartz's natural durability. Visually, pure quartz displays natural variations with unique veins and colors, while man-made quartz provides consistent patterns and a wide palette of colors, making it ideal for uniform aesthetics in design applications.

Color and Design Options: Variability in Man-Made vs Pure Quartz

Man-made quartz offers an extensive range of color and design options due to the ability to customize pigments and patterns during manufacturing, allowing for consistent and vibrant finishes. Pure quartz, sourced naturally, displays a more limited and subtle color palette, typically featuring translucent or milky white tones with occasional natural veining. The variability in man-made quartz provides greater flexibility for interior design applications, while pure quartz appeals to those seeking unique, organic aesthetics.

Performance in Home Applications: Countertops, Flooring, and More

Man-made quartz offers superior durability and stain resistance compared to pure quartz, making it ideal for high-traffic home applications like countertops and flooring. Engineered with resins and pigments, man-made quartz resists scratches and heat more effectively than natural quartz, which can be porous and prone to chipping. This enhanced performance ensures longevity and low maintenance in kitchens, bathrooms, and living spaces.

Maintenance and Care: Cleaning and Longevity

Man-made quartz surfaces require simple maintenance with non-abrasive cleaners to prevent damage and maintain their polished finish, whereas pure quartz, being a natural stone, demands periodic sealing to protect against stains and moisture. Cleaning man-made quartz involves mild soap and water, enhancing longevity by resisting scratches and discoloration, while pure quartz's porous nature necessitates specialized stone cleaners to avoid etching. Proper care of both materials ensures durability, but engineered quartz generally offers greater resistance to wear, making it a preferred choice for long-term durability.

Environmental Impact: Sustainability of Man-Made and Natural Quartz

Man-made quartz, often manufactured using recycled materials and resin binders, offers a more sustainable alternative by reducing the extraction impact associated with natural quartz mining. Natural quartz extraction involves significant land disruption, energy consumption, and habitat loss, contributing to environmental degradation. The durability and longevity of man-made quartz surfaces also minimize waste and resource use over time compared to harvested pure quartz.

Cost Comparison: Price Factors and Affordability

Man-made quartz, composed of about 90% crushed natural quartz combined with resins and pigments, generally costs between $50 and $150 per square foot, offering greater affordability compared to pure quartz, which can exceed $200 per square foot due to mining and processing expenses. Price factors for man-made quartz include manufacturing efficiency, consistency in quality, and lower raw material costs, making it a budget-friendly choice for kitchen countertops and surfaces. In contrast, pure quartz's higher price reflects its natural extraction, rarity, and lack of synthetic additives, leading to greater investment but often superior natural variation and durability.

Choosing the Right Quartz: Man-Made or Pure for Your Needs

Man-made quartz, engineered by blending natural quartz crystals with resins and pigments, offers durability and a wide range of colors ideal for countertops and interior design. Pure quartz, a naturally occurring mineral composed of silicon dioxide, provides unmatched hardness and chemical resistance, preferred in industrial applications and jewelry. Selecting the right quartz depends on your need for customization, durability, or natural authenticity, balancing aesthetic preferences with functional requirements.

Man-Made Quartz vs Pure Quartz Infographic

materialdif.com

materialdif.com