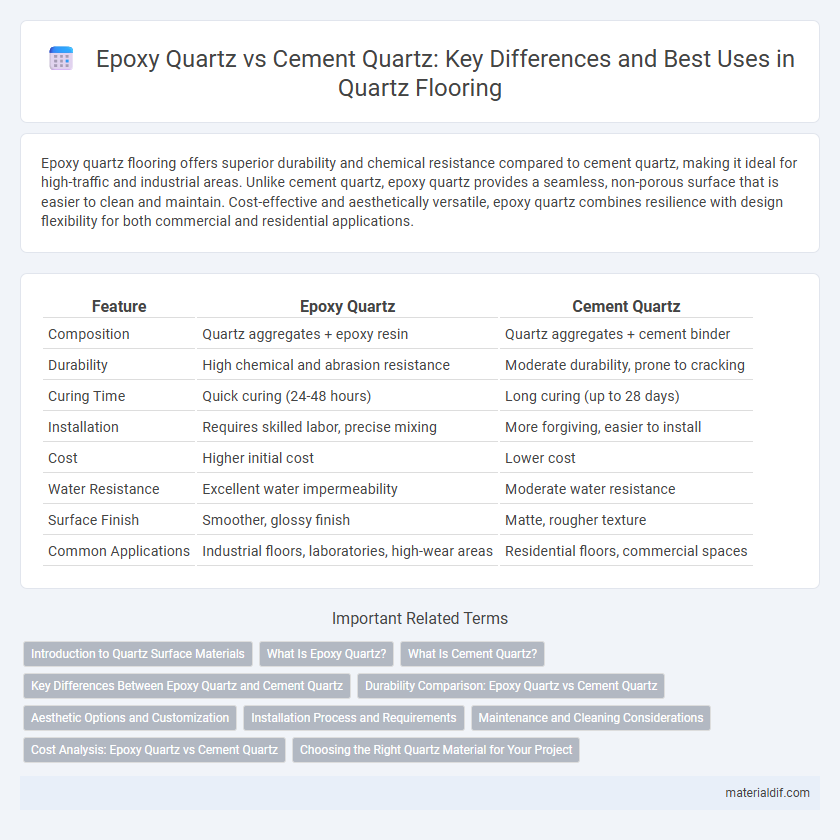

Epoxy quartz flooring offers superior durability and chemical resistance compared to cement quartz, making it ideal for high-traffic and industrial areas. Unlike cement quartz, epoxy quartz provides a seamless, non-porous surface that is easier to clean and maintain. Cost-effective and aesthetically versatile, epoxy quartz combines resilience with design flexibility for both commercial and residential applications.

Table of Comparison

| Feature | Epoxy Quartz | Cement Quartz |

|---|---|---|

| Composition | Quartz aggregates + epoxy resin | Quartz aggregates + cement binder |

| Durability | High chemical and abrasion resistance | Moderate durability, prone to cracking |

| Curing Time | Quick curing (24-48 hours) | Long curing (up to 28 days) |

| Installation | Requires skilled labor, precise mixing | More forgiving, easier to install |

| Cost | Higher initial cost | Lower cost |

| Water Resistance | Excellent water impermeability | Moderate water resistance |

| Surface Finish | Smoother, glossy finish | Matte, rougher texture |

| Common Applications | Industrial floors, laboratories, high-wear areas | Residential floors, commercial spaces |

Introduction to Quartz Surface Materials

Quartz surface materials combine natural quartz crystals with resin binders to create durable, non-porous countertops. Epoxy quartz features a high concentration of resin that enhances stain resistance and flexibility, while cement quartz incorporates cementitious materials for increased texture and a more rugged appearance. Both types offer superior hardness and versatility, making them popular choices for kitchen and bathroom surfaces.

What Is Epoxy Quartz?

Epoxy quartz is a composite material made by mixing quartz sand with epoxy resin, creating a durable and non-porous surface widely used for flooring and countertops. This material offers superior resistance to stains, chemicals, and abrasion compared to traditional cement quartz, making it ideal for high-traffic or industrial environments. Its seamless finish and easy maintenance contribute to its growing popularity in commercial and residential applications.

What Is Cement Quartz?

Cement quartz is a composite material combining quartz aggregates with Portland cement, resulting in a durable and cost-effective surface used in flooring and countertops. Unlike epoxy quartz, which uses epoxy resin as a binder, cement quartz offers enhanced breathability and environmental friendliness but may require longer curing times and be more susceptible to stains. Its natural strength and resistance to heavy traffic make cement quartz a popular choice for industrial and commercial applications.

Key Differences Between Epoxy Quartz and Cement Quartz

Epoxy quartz flooring consists of quartz aggregates bound with epoxy resin, resulting in a seamless, highly durable, and chemically resistant surface ideal for industrial and commercial environments. Cement quartz flooring uses quartz particles embedded in a cementitious matrix, offering superior compressive strength and better resistance to mechanical impact but with longer curing times and potential for micro-cracking. Key differences include epoxy quartz's faster installation and superior chemical resistance, while cement quartz provides enhanced load-bearing capacity and thermal stability.

Durability Comparison: Epoxy Quartz vs Cement Quartz

Epoxy quartz flooring offers superior durability compared to cement quartz due to its enhanced resistance to chemicals, stains, and abrasions, making it ideal for heavy traffic areas. Cement quartz, while cost-effective and easier to repair, is more prone to chipping and wear over time under similar stress conditions. The epoxy binder creates a denser, non-porous surface that extends the lifespan of quartz floors beyond what is typically achievable with cement-based materials.

Aesthetic Options and Customization

Epoxy quartz offers superior aesthetic options and customization compared to cement quartz, allowing a broader range of colors, patterns, and finishes due to its resin-based composition. The smooth, glossy surface of epoxy quartz can mimic natural stones and is highly versatile in design, making it ideal for modern, high-end applications. Cement quartz, while durable, typically presents a more limited color palette and a matte finish, restricting customization and visual variety.

Installation Process and Requirements

Epoxy quartz flooring requires a thorough surface preparation including cleaning, degreasing, and priming to ensure strong adhesion, followed by mixing epoxy resin with quartz granules before application and curing. Cement quartz flooring involves mixing quartz aggregates with cement and water, poured and leveled directly onto the substrate, requiring longer curing time and moisture control measures. Epoxy quartz offers faster installation and early foot traffic readiness, whereas cement quartz demands precise moisture barriers and extended curing to prevent cracking.

Maintenance and Cleaning Considerations

Epoxy quartz surfaces require minimal maintenance due to their non-porous nature, making cleaning simple with mild detergents and water, and resisting stains and moisture effectively. Cement quartz, being more porous, demands regular sealing to prevent staining and moisture penetration, alongside routine cleaning with pH-neutral cleaners to maintain its appearance. Proper upkeep of epoxy quartz significantly reduces long-term maintenance costs compared to cement quartz, which can incur higher expenses due to frequent sealing and potential repairs.

Cost Analysis: Epoxy Quartz vs Cement Quartz

Epoxy quartz surfaces typically cost more upfront than cement quartz due to higher material prices and specialized application processes. Epoxy quartz offers enhanced durability and a seamless finish, potentially reducing long-term maintenance expenses compared to cement quartz, which may require more frequent repairs and resurfacing. Evaluating total lifecycle costs reveals epoxy quartz as a cost-effective choice for high-traffic areas despite its initial premium.

Choosing the Right Quartz Material for Your Project

Epoxy quartz combines resin with quartz aggregates, offering superior durability and chemical resistance compared to cement quartz, which uses cement as the binder and tends to be more porous and less resistant to stains. Epoxy quartz is ideal for high-traffic or industrial environments, providing a seamless, non-porous surface that withstands heavy wear and exposure to harsh substances. Cement quartz suits residential or decorative projects where cost-effectiveness and ease of installation are priorities, despite requiring more maintenance to prevent staining and cracking.

Epoxy Quartz vs Cement Quartz Infographic

materialdif.com

materialdif.com