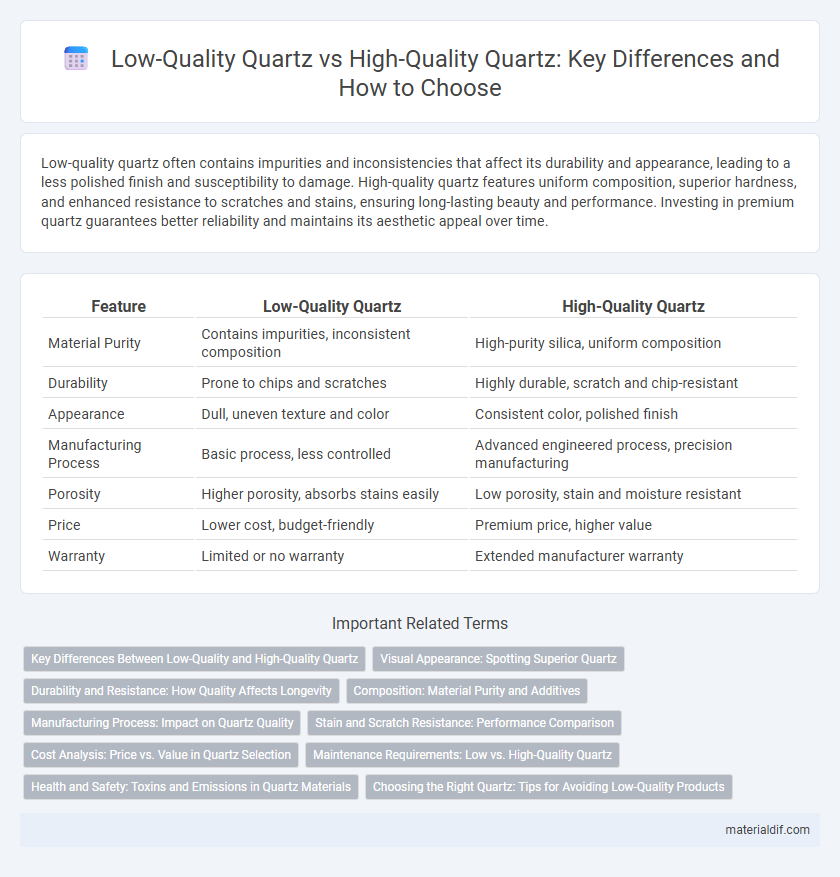

Low-quality quartz often contains impurities and inconsistencies that affect its durability and appearance, leading to a less polished finish and susceptibility to damage. High-quality quartz features uniform composition, superior hardness, and enhanced resistance to scratches and stains, ensuring long-lasting beauty and performance. Investing in premium quartz guarantees better reliability and maintains its aesthetic appeal over time.

Table of Comparison

| Feature | Low-Quality Quartz | High-Quality Quartz |

|---|---|---|

| Material Purity | Contains impurities, inconsistent composition | High-purity silica, uniform composition |

| Durability | Prone to chips and scratches | Highly durable, scratch and chip-resistant |

| Appearance | Dull, uneven texture and color | Consistent color, polished finish |

| Manufacturing Process | Basic process, less controlled | Advanced engineered process, precision manufacturing |

| Porosity | Higher porosity, absorbs stains easily | Low porosity, stain and moisture resistant |

| Price | Lower cost, budget-friendly | Premium price, higher value |

| Warranty | Limited or no warranty | Extended manufacturer warranty |

Key Differences Between Low-Quality and High-Quality Quartz

Low-quality quartz often contains higher levels of impurities and inconsistent crystal structures, leading to reduced durability and a duller appearance, whereas high-quality quartz exhibits uniform composition and exceptional clarity with fewer inclusions. The manufacturing process of high-quality quartz includes precise purification and controlled crystallization, enhancing its strength, resistance to scratches, and color vibrancy compared to low-grade counterparts. Performance metrics such as Mohs hardness and thermal stability significantly differ, making high-quality quartz the preferred choice for demanding industrial and aesthetic applications.

Visual Appearance: Spotting Superior Quartz

High-quality quartz exhibits a consistent, vibrant color with natural translucency and minimal imperfections, while low-quality quartz often appears dull, with uneven coloration and visible impurities. Superior quartz showcases a smooth, polished surface that enhances its brightness and depth, contrasting with the rough or cloudy finish seen in inferior samples. Spotting high-quality quartz involves examining clarity, color uniformity, and surface texture to ensure authenticity and aesthetic appeal.

Durability and Resistance: How Quality Affects Longevity

High-quality quartz demonstrates superior durability and resistance to scratches, stains, and heat, ensuring longer-lasting surfaces in demanding environments. Low-quality quartz often contains higher resin content and inferior aggregates, making it more prone to chipping, fading, and damage over time. The longevity of quartz countertops heavily depends on the material's quality, impacting maintenance requirements and overall aesthetic retention.

Composition: Material Purity and Additives

Low-quality quartz typically contains a higher proportion of impurities and additives, such as resin binders and recycled materials, which can compromise its durability and aesthetic uniformity. High-quality quartz features a consistently high silica content, often exceeding 90%, with minimal additives to ensure greater hardness, scratch resistance, and color stability. The purity and controlled composition of high-quality quartz result in superior performance and longevity compared to lower-grade counterparts.

Manufacturing Process: Impact on Quartz Quality

Low-quality quartz often results from improper manufacturing processes such as insufficient purity control and inadequate crushing techniques, leading to impurities and inconsistent particle sizes. High-quality quartz undergoes stringent purification methods like acid washing and precise milling to achieve uniformity and high chemical purity essential for advanced industrial applications. The manufacturing process directly impacts quartz's structural integrity, optical clarity, and suitability for use in electronics, optics, and high-performance composites.

Stain and Scratch Resistance: Performance Comparison

High-quality quartz exhibits superior stain and scratch resistance due to its dense composition and advanced manufacturing processes, making it ideal for kitchen countertops and high-traffic areas. Low-quality quartz often contains impurities and lacks uniform hardness, resulting in increased susceptibility to stains and surface scratches over time. This performance disparity highlights the importance of selecting premium quartz materials for durability and long-term aesthetic appeal.

Cost Analysis: Price vs. Value in Quartz Selection

Low-quality quartz typically costs less upfront but may incur higher long-term expenses due to reduced durability and increased maintenance needs, diminishing overall value. High-quality quartz surfaces command premium prices but offer superior resistance to scratches, stains, and heat, providing better longevity and cost-efficiency. Evaluating cost versus value in quartz selection requires balancing initial investment against expected lifespan and performance in kitchen or bathroom applications.

Maintenance Requirements: Low vs. High-Quality Quartz

Low-quality quartz surfaces often require more frequent sealing and are prone to staining, making maintenance time-consuming and costly. High-quality quartz, engineered with superior resins and natural quartz particles, offers enhanced durability and stain resistance, reducing the need for extensive upkeep. Regular cleaning with mild detergents ensures longevity while preserving the surface's appearance regardless of the quartz grade.

Health and Safety: Toxins and Emissions in Quartz Materials

Low-quality quartz often contains higher levels of impurities and toxic substances such as silica dust, which pose significant health risks including respiratory issues and silicosis when inhaled during cutting or installation. High-quality quartz is engineered to minimize the release of hazardous emissions, ensuring safer indoor air quality and compliance with health regulations. Proper ventilation and protective equipment are essential when working with any quartz material to mitigate potential toxin exposure and maintain a safe environment.

Choosing the Right Quartz: Tips for Avoiding Low-Quality Products

Choosing the right quartz involves evaluating factors such as slab density, consistent veining, and resistance to scratches and stains to avoid low-quality products that may deteriorate quickly. High-quality quartz features a smooth, polished surface with minimal pores, enhancing durability and aesthetic appeal in kitchen countertops and bathrooms. Verifying certifications, warranties, and supplier reputations can further ensure investment in premium quartz materials.

Low-Quality Quartz vs High-Quality Quartz Infographic

materialdif.com

materialdif.com