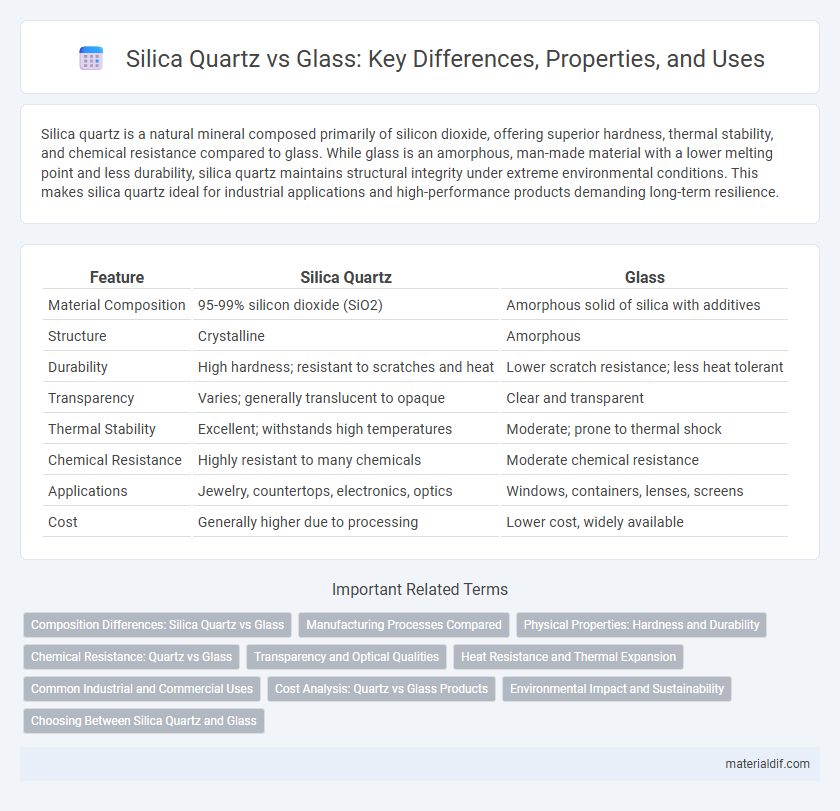

Silica quartz is a natural mineral composed primarily of silicon dioxide, offering superior hardness, thermal stability, and chemical resistance compared to glass. While glass is an amorphous, man-made material with a lower melting point and less durability, silica quartz maintains structural integrity under extreme environmental conditions. This makes silica quartz ideal for industrial applications and high-performance products demanding long-term resilience.

Table of Comparison

| Feature | Silica Quartz | Glass |

|---|---|---|

| Material Composition | 95-99% silicon dioxide (SiO2) | Amorphous solid of silica with additives |

| Structure | Crystalline | Amorphous |

| Durability | High hardness; resistant to scratches and heat | Lower scratch resistance; less heat tolerant |

| Transparency | Varies; generally translucent to opaque | Clear and transparent |

| Thermal Stability | Excellent; withstands high temperatures | Moderate; prone to thermal shock |

| Chemical Resistance | Highly resistant to many chemicals | Moderate chemical resistance |

| Applications | Jewelry, countertops, electronics, optics | Windows, containers, lenses, screens |

| Cost | Generally higher due to processing | Lower cost, widely available |

Composition Differences: Silica Quartz vs Glass

Silica quartz primarily consists of crystalline silicon dioxide (SiO2) with a well-ordered atomic structure, giving it unique optical and thermal properties. In contrast, glass is typically an amorphous solid composed of silica combined with various oxides such as sodium oxide (Na2O) and calcium oxide (CaO), which disrupt the crystalline structure to create a non-crystalline, transparent material. These composition differences result in silica quartz having higher chemical purity and thermal stability compared to common soda-lime or borosilicate glass.

Manufacturing Processes Compared

Silica quartz is produced through natural crystallization or synthetic growth processes like the hydrothermal method, ensuring high purity and structural consistency essential for advanced industrial applications. Glass manufacturing involves melting silica sand with additives at high temperatures followed by rapid cooling to form an amorphous, non-crystalline solid, allowing for versatile shaping and mass production. The distinct crystallinity in silica quartz results in superior thermal stability and mechanical strength compared to the brittle and less heat-resistant glass formed by conventional glassmaking techniques.

Physical Properties: Hardness and Durability

Silica quartz exhibits superior hardness compared to glass, with a Mohs hardness of approximately 7 versus glass's hardness of about 5.5, making quartz significantly more resistant to scratches and abrasions. The durability of silica quartz also surpasses that of glass due to its crystalline structure, which provides greater resistance to impact and chemical corrosion. This enhanced physical resilience makes silica quartz ideal for applications requiring long-lasting material performance.

Chemical Resistance: Quartz vs Glass

Silica quartz exhibits superior chemical resistance compared to conventional glass, with exceptional stability against acids, alkalis, and solvents due to its pure silicon dioxide composition. Glass, often containing various metal oxides, is more susceptible to chemical attack and corrosion, particularly by hydrofluoric acid and strong alkalis. Quartz's high resistance makes it ideal for harsh chemical environments and industrial applications requiring sustained durability.

Transparency and Optical Qualities

Silica quartz exhibits superior transparency and optical clarity compared to standard glass due to its high purity and uniform crystalline structure, allowing more light to pass through with less distortion. Its refractive index of approximately 1.54 enhances light transmission and reduces chromatic aberration, making it ideal for precision optical applications. Glass, while transparent, often contains impurities and has a variable refractive index around 1.5, which can result in lower optical performance and increased light scattering.

Heat Resistance and Thermal Expansion

Silica quartz exhibits superior heat resistance compared to glass, maintaining structural integrity at temperatures exceeding 1,000degC, whereas most glass types begin to soften around 550degC to 600degC. The thermal expansion coefficient of silica quartz is significantly lower, approximately 0.5 x 10^-6 /degC, which reduces the risk of thermal shock and cracking under rapid temperature changes, unlike glass which has higher expansion rates near 9 x 10^-6 /degC. These properties make silica quartz ideal for high-temperature applications in industrial and scientific equipment where dimensional stability and thermal durability are critical.

Common Industrial and Commercial Uses

Silica quartz is widely used in electronics manufacturing, optical devices, and semiconductor industries due to its high thermal stability and excellent electrical insulation properties, whereas glass finds common applications in windows, containers, and packaging due to its transparency and ease of molding. Industrial quartz is essential in producing silicon wafers, fiber optics, and precision lenses, while glass is primarily utilized in construction, automotive, and consumer goods for its versatility and cost-effectiveness. Both materials serve critical roles in manufacturing, but silica quartz is preferred in high-tech environments requiring purity and durability, contrasting with glass's broad commercial applications.

Cost Analysis: Quartz vs Glass Products

Silica quartz products typically have higher upfront costs compared to glass due to their durability, heat resistance, and aesthetic appeal in construction and design applications. Glass products, while more affordable initially, may incur additional maintenance or replacement expenses over time because of their lower resistance to scratches and thermal stress. Evaluating the total cost of ownership highlights quartz as a cost-effective long-term investment despite the higher initial expenditure.

Environmental Impact and Sustainability

Silica quartz demonstrates superior environmental benefits compared to glass, primarily due to its abundant natural availability and lower energy consumption in extraction and processing. Production of quartz surfaces emits fewer greenhouse gases and results in less waste, contributing to a smaller carbon footprint. Additionally, silica quartz's durability and recyclability enhance its sustainability profile, making it a preferred material in eco-friendly construction and design.

Choosing Between Silica Quartz and Glass

Silica quartz offers superior thermal stability and scratch resistance compared to glass, making it ideal for applications requiring durability under extreme conditions. Glass is generally more affordable and easier to shape, suitable for decorative or less demanding uses. Choosing between silica quartz and glass depends on prioritizing performance attributes such as heat resistance and mechanical strength versus cost-effectiveness and design flexibility.

Silica Quartz vs Glass Infographic

materialdif.com

materialdif.com