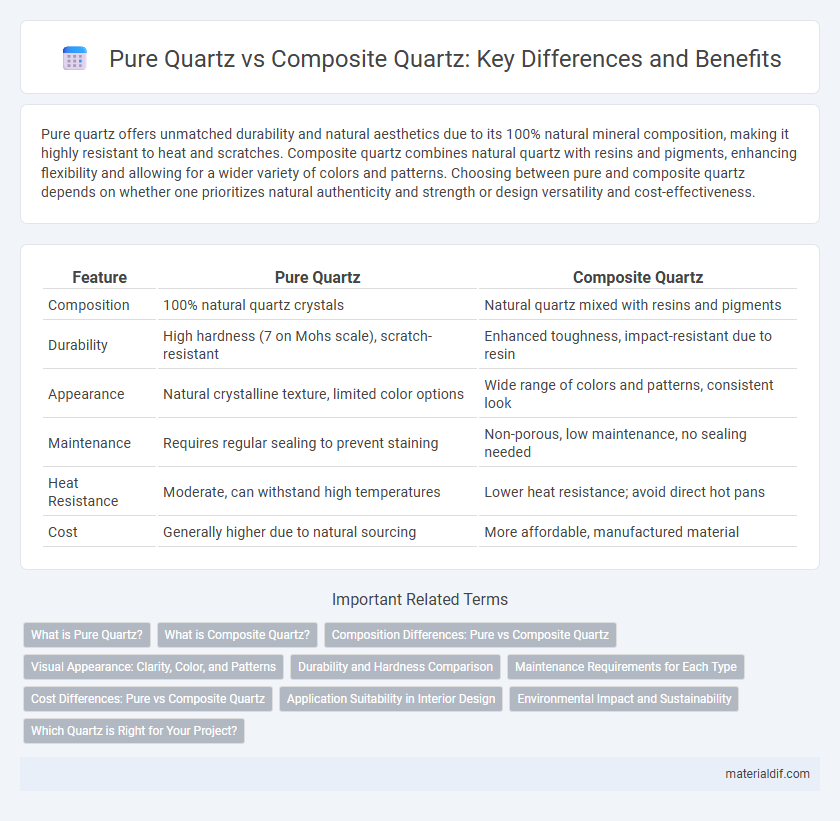

Pure quartz offers unmatched durability and natural aesthetics due to its 100% natural mineral composition, making it highly resistant to heat and scratches. Composite quartz combines natural quartz with resins and pigments, enhancing flexibility and allowing for a wider variety of colors and patterns. Choosing between pure and composite quartz depends on whether one prioritizes natural authenticity and strength or design versatility and cost-effectiveness.

Table of Comparison

| Feature | Pure Quartz | Composite Quartz |

|---|---|---|

| Composition | 100% natural quartz crystals | Natural quartz mixed with resins and pigments |

| Durability | High hardness (7 on Mohs scale), scratch-resistant | Enhanced toughness, impact-resistant due to resin |

| Appearance | Natural crystalline texture, limited color options | Wide range of colors and patterns, consistent look |

| Maintenance | Requires regular sealing to prevent staining | Non-porous, low maintenance, no sealing needed |

| Heat Resistance | Moderate, can withstand high temperatures | Lower heat resistance; avoid direct hot pans |

| Cost | Generally higher due to natural sourcing | More affordable, manufactured material |

What is Pure Quartz?

Pure quartz is a naturally occurring mineral composed of silicon dioxide (SiO2) with a crystalline structure that forms transparent to translucent crystals. It is prized for its durability, resistance to heat, and chemical inertness, making it ideal for various industrial applications and electronics. Unlike composite quartz, which combines natural quartz with resins and pigments, pure quartz remains unaltered and retains its natural physical and chemical properties.

What is Composite Quartz?

Composite quartz, also known as engineered quartz, is a man-made material composed of approximately 90-95% natural quartz crystals combined with resins, polymers, and pigments. This mixture enhances durability, non-porosity, and stain resistance, making it a popular choice for kitchen countertops and surfaces. Unlike pure quartz, which is a natural mineral, composite quartz offers greater color consistency and design versatility through manufacturing processes.

Composition Differences: Pure vs Composite Quartz

Pure quartz consists of 100% natural crystalline silica, offering exceptional hardness and durability, while composite quartz combines crushed natural quartz with resin and pigments, enhancing design flexibility and stain resistance. The resin binder in composite quartz increases resistance to chipping and cracking but slightly reduces heat tolerance compared to pure quartz slabs. Manufacturing processes of composite quartz enable uniformity in color and pattern, whereas pure quartz showcases natural variation inherent in mined stone.

Visual Appearance: Clarity, Color, and Patterns

Pure quartz exhibits exceptional clarity with a naturally translucent to transparent appearance, often showcasing subtle color variations from clear to milky white. Composite quartz combines natural quartz crystals with resins and pigments, resulting in a wide range of vibrant colors and intricate patterns that mimic natural stone or offer more uniform aesthetics. The visual appeal of composite quartz can be customized extensively, whereas pure quartz maintains a more organic and understated look due to its natural formation.

Durability and Hardness Comparison

Pure quartz exhibits exceptional hardness, rating 7 on the Mohs scale, which makes it highly resistant to scratching and wear. Composite quartz, engineered by blending crushed quartz with resins and pigments, enhances durability by combining natural quartz's strength with improved flexibility and stain resistance. The integration of resins in composite quartz surfaces results in superior impact resistance and lower susceptibility to chipping compared to pure quartz slabs.

Maintenance Requirements for Each Type

Pure quartz surfaces typically require more frequent sealing and careful cleaning with pH-balanced products to prevent staining and damage, as natural quartz is more porous. Composite quartz, made from crushed quartz and resin, boasts enhanced durability and stain resistance, reducing the need for sealing and allowing for easier maintenance with mild soap and water. Both types benefit from prompt spill cleanup, but composite quartz offers superior resilience against scratches and heat, minimizing overall upkeep.

Cost Differences: Pure vs Composite Quartz

Pure quartz is significantly more expensive than composite quartz due to its natural extraction process and higher purity levels, resulting in a premium price per square foot. Composite quartz, made from crushed natural quartz combined with resins and pigments, offers a cost-effective alternative while maintaining considerable durability and aesthetic appeal. Consumers often choose composite quartz for budget-friendly projects without sacrificing the appearance and strength associated with pure quartz surfaces.

Application Suitability in Interior Design

Pure quartz offers exceptional durability and natural aesthetic appeal, making it ideal for high-traffic interior spaces such as kitchen countertops and bathroom vanities where resistance to scratches and heat is essential. Composite quartz, composed of crushed quartz mixed with resin, provides enhanced versatility with customizable colors and patterns, suited for decorative wall panels and flooring that demand unique design elements. Both materials excel in interior design, but pure quartz is preferred for functional surfaces requiring high performance, while composite quartz fits creative applications emphasizing style and adaptability.

Environmental Impact and Sustainability

Pure quartz, a naturally occurring mineral, has minimal environmental impact when responsibly sourced but requires significant energy for extraction and processing. Composite quartz, made from crushed quartz mixed with resin and pigments, offers enhanced durability and reduces the need for non-renewable materials, promoting sustainability through longer lifespan and recyclability. Both materials demand careful consideration of mining practices, resin content, and end-of-life disposal to optimize environmental benefits.

Which Quartz is Right for Your Project?

Pure quartz offers unmatched durability and natural beauty, making it ideal for high-end projects requiring authentic stone aesthetics. Composite quartz combines crushed quartz with resins and pigments, providing enhanced flexibility, uniformity, and cost-effectiveness for versatile applications. Choosing the right quartz depends on your project's budget, design preferences, and performance requirements.

Pure Quartz vs Composite Quartz Infographic

materialdif.com

materialdif.com