Nano quartz features particles measured at the nanometer scale, offering enhanced surface smoothness and durability compared to regular quartz. This advanced material provides superior resistance to scratches and stains, making it ideal for high-traffic surfaces. Regular quartz, while durable, lacks the refined precision and performance benefits of nano quartz in demanding applications.

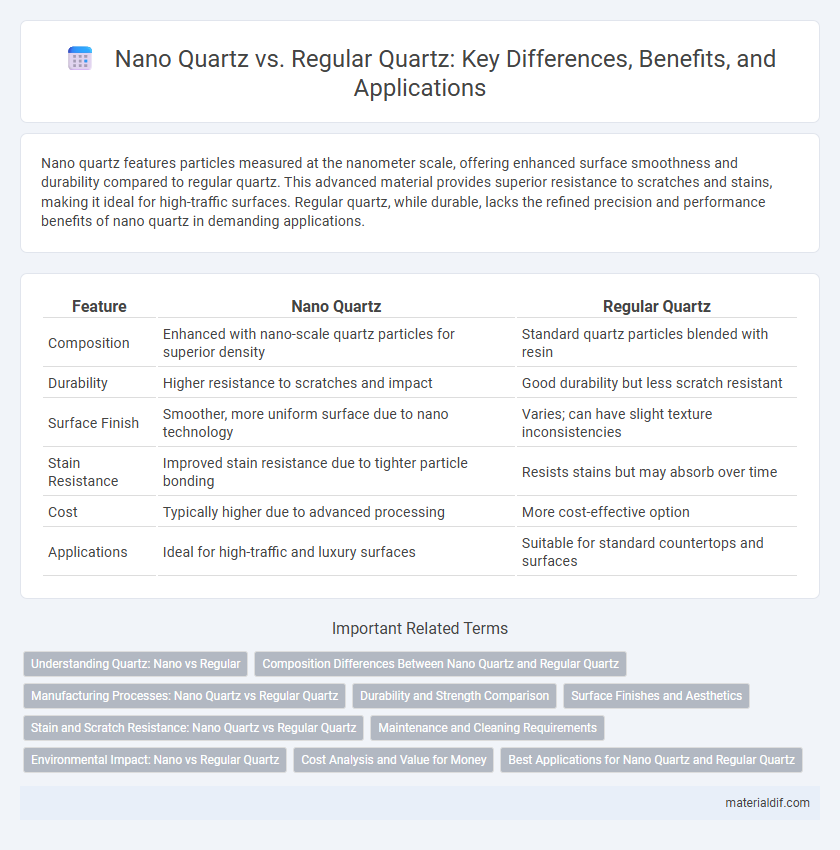

Table of Comparison

| Feature | Nano Quartz | Regular Quartz |

|---|---|---|

| Composition | Enhanced with nano-scale quartz particles for superior density | Standard quartz particles blended with resin |

| Durability | Higher resistance to scratches and impact | Good durability but less scratch resistant |

| Surface Finish | Smoother, more uniform surface due to nano technology | Varies; can have slight texture inconsistencies |

| Stain Resistance | Improved stain resistance due to tighter particle bonding | Resists stains but may absorb over time |

| Cost | Typically higher due to advanced processing | More cost-effective option |

| Applications | Ideal for high-traffic and luxury surfaces | Suitable for standard countertops and surfaces |

Understanding Quartz: Nano vs Regular

Nano quartz features particles measured at the nanometer scale, enhancing its density and surface smoothness compared to regular quartz. This results in superior resistance to scratches, stains, and heat, making nano quartz ideal for high-performance countertops and industrial applications. Regular quartz, composed of larger crystalline structures, offers durability and aesthetic appeal but lacks the enhanced mechanical properties of nano quartz.

Composition Differences Between Nano Quartz and Regular Quartz

Nano Quartz consists of quartz particles reduced to the nanometer scale, enhancing surface area and reactivity compared to Regular Quartz with larger, micrometer-sized particles. The nanostructure of Nano Quartz provides improved mechanical properties and increased chemical stability due to the altered crystalline arrangement. Regular Quartz predominantly features a bulk crystalline form with lower surface energy and less reactive sites compared to the highly reactive surfaces found in Nano Quartz.

Manufacturing Processes: Nano Quartz vs Regular Quartz

Nano quartz is manufactured using advanced nanotechnology techniques that break down quartz particles into nanometer-sized crystals, enhancing surface area and structural uniformity. Regular quartz is typically processed through traditional crushing and heating methods that yield larger crystalline structures with less precision. The nano quartz manufacturing process allows for superior durability, enhanced optical properties, and increased resistance to wear compared to regular quartz.

Durability and Strength Comparison

Nano quartz exhibits superior durability and strength compared to regular quartz due to its advanced nanotechnology-infused composition. The compact nanostructure of nano quartz enhances its resistance to scratches, fractures, and heat, making it ideal for high-traffic or demanding environments. Regular quartz, while naturally robust, lacks the enhanced mechanical properties that nanotechnology imparts, resulting in relatively lower performance under stress.

Surface Finishes and Aesthetics

Nano Quartz offers a superior surface finish compared to regular quartz, featuring a denser, smoother texture due to its microscopic particle size. This results in enhanced aesthetic appeal with a more uniform color distribution and higher gloss levels, providing a sleek, modern look. Regular quartz surfaces may exhibit slight texture variations and lower gloss, making Nano Quartz ideal for premium applications demanding both durability and refined visual impact.

Stain and Scratch Resistance: Nano Quartz vs Regular Quartz

Nano quartz exhibits superior stain resistance compared to regular quartz due to its dense, non-porous surface that prevents liquids and oils from penetrating. This advanced material also offers enhanced scratch resistance, maintaining its polished finish longer under daily wear and tear. The embedded nano-particles within nano quartz increase durability, making it an ideal choice for high-traffic areas and kitchen countertops.

Maintenance and Cleaning Requirements

Nano quartz surfaces require less maintenance compared to regular quartz due to their enhanced resistance to stains and scratches. Their non-porous nature minimizes the need for harsh chemical cleaners, allowing simple wiping with mild soap and water to maintain cleanliness. Regular quartz may need more frequent sealing and careful cleaning to prevent discoloration and damage from abrasive materials.

Environmental Impact: Nano vs Regular Quartz

Nano quartz production consumes significantly less energy compared to regular quartz, reducing the carbon footprint associated with extraction and processing. The smaller particle size in nano quartz improves material efficiency, minimizing raw material waste and lowering environmental degradation. Additionally, nano quartz's enhanced durability extends product lifespan, decreasing the frequency of replacements and overall resource consumption.

Cost Analysis and Value for Money

Nano quartz offers a higher initial cost compared to regular quartz due to its advanced manufacturing process, but it provides superior durability and stain resistance, leading to lower maintenance expenses over time. Regular quartz is more affordable upfront, making it a budget-friendly choice for immediate installation needs. When evaluating value for money, nano quartz's longevity and enhanced performance often justify the premium price through extended lifespan and reduced repair costs.

Best Applications for Nano Quartz and Regular Quartz

Nano quartz features particles engineered at the nanoscale, providing enhanced hardness and superior scratch resistance, making it ideal for high-traffic surfaces such as kitchen countertops and commercial flooring. Regular quartz, composed of larger crystalline structures, offers excellent durability and aesthetic appeal, suitable for residential applications like bathroom vanities and decorative wall cladding. Nano quartz excels in environments demanding higher resistance to wear and chemical exposure, while regular quartz is preferred for standard durability with a focus on design versatility.

Nano Quartz vs Regular Quartz Infographic

materialdif.com

materialdif.com