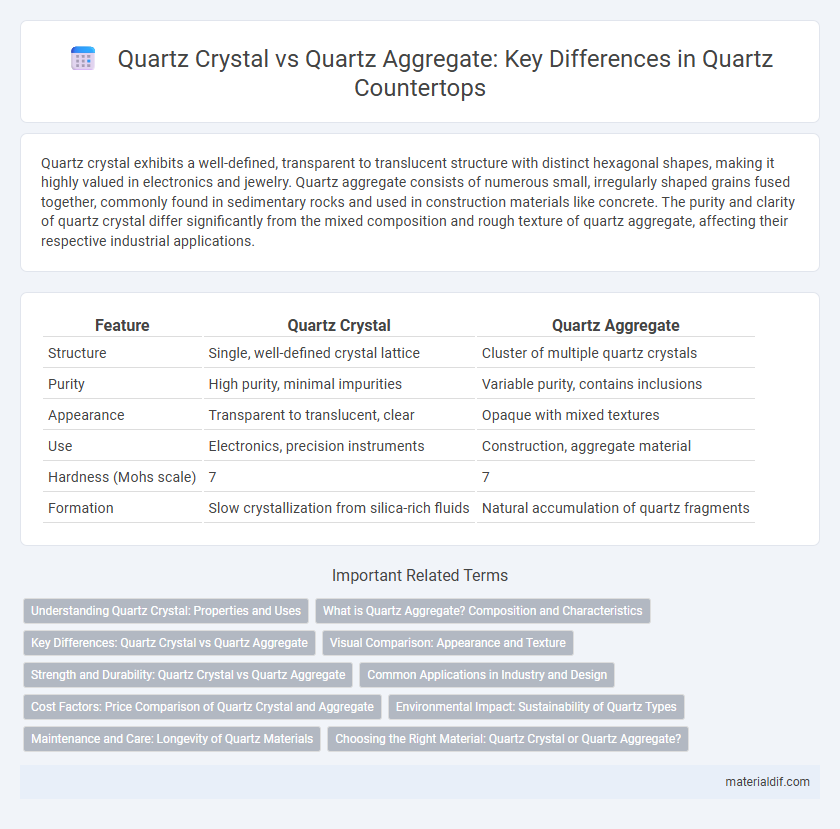

Quartz crystal exhibits a well-defined, transparent to translucent structure with distinct hexagonal shapes, making it highly valued in electronics and jewelry. Quartz aggregate consists of numerous small, irregularly shaped grains fused together, commonly found in sedimentary rocks and used in construction materials like concrete. The purity and clarity of quartz crystal differ significantly from the mixed composition and rough texture of quartz aggregate, affecting their respective industrial applications.

Table of Comparison

| Feature | Quartz Crystal | Quartz Aggregate |

|---|---|---|

| Structure | Single, well-defined crystal lattice | Cluster of multiple quartz crystals |

| Purity | High purity, minimal impurities | Variable purity, contains inclusions |

| Appearance | Transparent to translucent, clear | Opaque with mixed textures |

| Use | Electronics, precision instruments | Construction, aggregate material |

| Hardness (Mohs scale) | 7 | 7 |

| Formation | Slow crystallization from silica-rich fluids | Natural accumulation of quartz fragments |

Understanding Quartz Crystal: Properties and Uses

Quartz crystal, a highly ordered form of silicon dioxide, exhibits piezoelectric properties that make it essential in oscillators and frequency control devices, providing precise timing in watches and electronics. Its hardness of 7 on the Mohs scale ensures durability and resistance to abrasion, ideal for optical instruments and laser technology. Quartz aggregate, in contrast, is a granular form used primarily in construction and industrial applications due to its physical strength and chemical inertness.

What is Quartz Aggregate? Composition and Characteristics

Quartz aggregate consists of naturally occurring quartz particles used in construction and manufacturing, primarily composed of silicon dioxide (SiO2) in a crystalline form. Characterized by its high hardness, chemical inertness, and resistance to weathering, quartz aggregate provides durability and strength in concrete and asphalt applications. Its angular shape and consistent grain size distribution contribute to enhanced mechanical bonding and stability in composite materials.

Key Differences: Quartz Crystal vs Quartz Aggregate

Quartz crystal is a naturally occurring, well-formed crystalline mineral with a hexagonal structure and high clarity, commonly used in electronics and precision instruments. Quartz aggregate consists of fragmented, irregularly shaped quartz particles found in concrete and construction materials, valued mainly for its durability and hardness. The key differences lie in their formation, purity, and applications: quartz crystal is a single, pure mineral crystal, while quartz aggregate is a composite of crushed quartz fragments.

Visual Comparison: Appearance and Texture

Quartz crystal displays a transparent to translucent appearance with a smooth, glass-like surface and distinct geometric facets, often forming well-defined hexagonal prisms. In contrast, quartz aggregate consists of irregular, opaque grains with a rough texture and lacks the clarity or uniform shape of individual crystals. Visually, quartz crystals catch and reflect light sharply due to their polished structure, whereas quartz aggregates present a duller, grainy look caused by their mixed mineral composition and fractured surfaces.

Strength and Durability: Quartz Crystal vs Quartz Aggregate

Quartz crystals exhibit superior strength and durability due to their well-ordered atomic structure and fewer internal flaws, making them ideal for precision instruments and high-stress applications. In contrast, quartz aggregates, composed of fragmented and naturally cemented particles, generally possess lower strength and variable durability depending on the cementing materials and environmental exposure. The intrinsic hardness of individual quartz crystals generally exceeds that of quartz aggregate masses, influencing their comparative performance in construction and industrial uses.

Common Applications in Industry and Design

Quartz crystal, characterized by its precise atomic structure and piezoelectric properties, is widely used in electronics for oscillators, sensors, and frequency control devices. Quartz aggregate, composed of crushed quartz particles, serves as a durable material in construction, road surfacing, and architectural design due to its hardness and chemical stability. Industrial applications leverage quartz crystal's high precision, while quartz aggregate's robustness supports structural and aesthetic purposes in design projects.

Cost Factors: Price Comparison of Quartz Crystal and Aggregate

Quartz crystal typically commands a higher price due to its purity, clarity, and suitability for electronic and optical applications, making it costlier than quartz aggregate, which is more common and used primarily in construction and landscaping. The cost of quartz aggregate is influenced by factors such as extraction ease, processing requirements, and local availability, resulting in a lower overall price compared to quartz crystal. Market demand and industrial application drive the price gap, with quartz crystal's specialized uses contributing to its premium cost.

Environmental Impact: Sustainability of Quartz Types

Quartz crystal mining typically has a lower environmental footprint compared to quartz aggregate extraction, as crystal mining often involves smaller, more controlled operations that minimize habitat disruption. Quartz aggregate production requires extensive quarrying, leading to greater land degradation, increased energy consumption, and higher carbon emissions. Sustainable practices in quartz crystal sourcing include careful site management and recycling, whereas sustainable quartz aggregate use emphasizes efficient processing and land reclamation.

Maintenance and Care: Longevity of Quartz Materials

Quartz crystals require delicate maintenance to preserve their natural luster, often involving gentle cleaning with mild soap and avoiding harsh chemicals that can damage the surface. Quartz aggregate, commonly used in engineered quartz surfaces, benefits from regular sealing and prompt removal of spills to prevent staining and prolong durability. Proper care tailored to each form enhances the longevity of quartz materials, ensuring sustained aesthetic appeal and functional performance in various applications.

Choosing the Right Material: Quartz Crystal or Quartz Aggregate?

Quartz crystal offers superior clarity, hardness, and piezoelectric properties, making it ideal for precision instruments and electronics, while quartz aggregate provides cost-effective bulk material commonly used in construction and industrial applications. Selecting quartz crystal ensures higher purity and structural integrity, essential for applications requiring exact acoustic or optical performance. Quartz aggregate suits projects prioritizing durability and volume over precision, such as concrete production or landscaping.

Quartz Crystal vs Quartz Aggregate Infographic

materialdif.com

materialdif.com