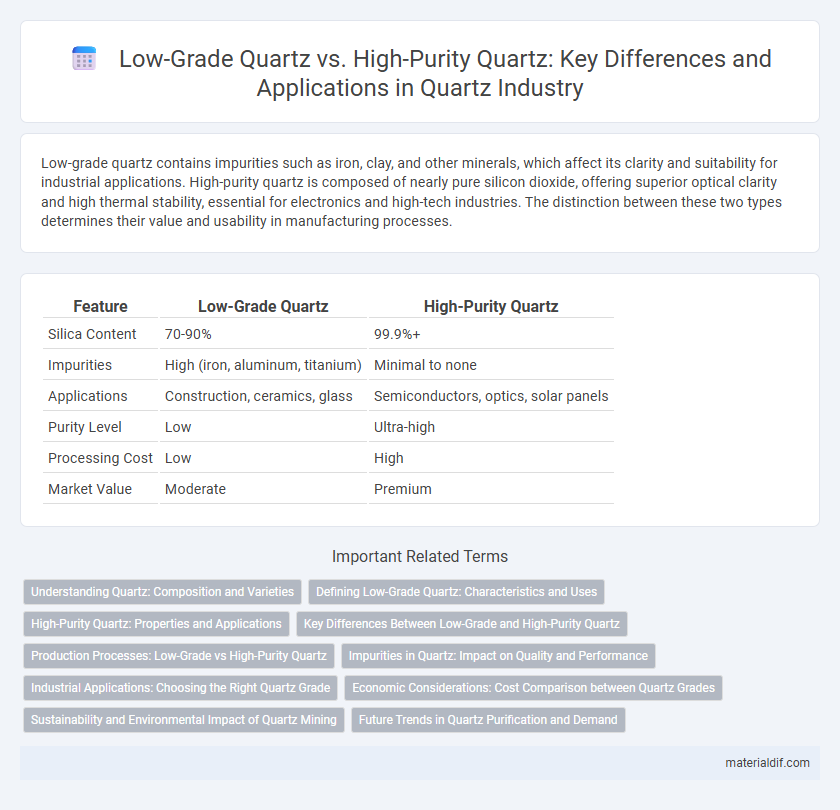

Low-grade quartz contains impurities such as iron, clay, and other minerals, which affect its clarity and suitability for industrial applications. High-purity quartz is composed of nearly pure silicon dioxide, offering superior optical clarity and high thermal stability, essential for electronics and high-tech industries. The distinction between these two types determines their value and usability in manufacturing processes.

Table of Comparison

| Feature | Low-Grade Quartz | High-Purity Quartz |

|---|---|---|

| Silica Content | 70-90% | 99.9%+ |

| Impurities | High (iron, aluminum, titanium) | Minimal to none |

| Applications | Construction, ceramics, glass | Semiconductors, optics, solar panels |

| Purity Level | Low | Ultra-high |

| Processing Cost | Low | High |

| Market Value | Moderate | Premium |

Understanding Quartz: Composition and Varieties

Quartz primarily consists of silicon dioxide (SiO2) and varies in purity levels, influencing its industrial applications. Low-grade quartz contains impurities such as iron oxide and aluminum, limiting its use in high-tech industries but suitable for construction and glass manufacturing. High-purity quartz features over 99.99% SiO2, essential for semiconductor, fiber optics, and solar panel production due to its exceptional clarity and chemical stability.

Defining Low-Grade Quartz: Characteristics and Uses

Low-grade quartz typically contains higher levels of impurities such as iron, aluminum, and titanium, which affect its color and industrial applicability. Its characteristics include a coarser texture and lower crystallinity compared to high-purity quartz, limiting its use primarily to construction aggregates, decorative stone, and certain glass manufacturing processes. Low-grade quartz's affordability and abundance make it suitable for applications where optical clarity and chemical purity are not critical.

High-Purity Quartz: Properties and Applications

High-purity quartz exhibits exceptional chemical purity, typically exceeding 99.99% silica content, which results in superior thermal and optical properties. Its low impurity levels make it ideal for advanced applications such as semiconductor manufacturing, optical fibers, and precision laboratory equipment. High-purity quartz's unique ability to withstand high temperatures and resist chemical corrosion enhances performance and reliability in high-tech industries.

Key Differences Between Low-Grade and High-Purity Quartz

Low-grade quartz contains higher levels of impurities such as iron, aluminum, and other minerals, which affect its color, transparency, and industrial applications, whereas high-purity quartz boasts over 99.9% silicon dioxide content, making it ideal for advanced technological uses like semiconductor manufacturing and optical devices. The crystallinity and particle size distribution also differ significantly, with high-purity quartz exhibiting consistent grain structures essential for precision industries, while low-grade quartz is typically used in construction and abrasive materials. Furthermore, the processing requirements vary, as high-purity quartz demands extensive refining and purification methods, in contrast to the minimal treatment low-grade quartz undergoes before utilization.

Production Processes: Low-Grade vs High-Purity Quartz

Low-grade quartz undergoes minimal processing, typically involving basic crushing and sorting to remove large impurities, making it suitable for construction and industrial use where purity is less critical. High-purity quartz requires extensive purification steps, including acid leaching, froth flotation, and thermal treatments to eliminate trace metal ions and other contaminants, essential for semiconductor, optical, and photovoltaic applications. Advanced chemical and mechanical refining techniques in high-purity quartz production ensure particle size uniformity and chemical composition precision, significantly differentiating it from low-grade quartz processing.

Impurities in Quartz: Impact on Quality and Performance

Low-grade quartz contains higher levels of impurities such as iron, aluminum, and titanium oxides, which negatively affect its optical clarity, chemical stability, and electrical properties. High-purity quartz, with impurity concentrations below 10 parts per million, exhibits superior performance in semiconductor manufacturing, fiber optics, and precision glassmaking due to its enhanced transparency and chemical inertness. The presence of impurities in quartz directly influences its melting point, refractive index, and durability, making purity a critical factor for advanced technological applications.

Industrial Applications: Choosing the Right Quartz Grade

Low-grade quartz finds extensive use in construction aggregates, glass manufacturing, and abrasive materials due to its lower silica content and higher impurity levels. High-purity quartz, characterized by over 99.9% silicon dioxide, is essential in semiconductor wafers, photovoltaic cells, and optical fibers where minimal contamination is critical. Selecting the appropriate quartz grade directly impacts product performance, cost efficiency, and process reliability in industrial applications.

Economic Considerations: Cost Comparison between Quartz Grades

Low-grade quartz typically incurs lower extraction costs but results in higher processing expenses due to impurities, affecting overall economic efficiency. High-purity quartz demands substantial upfront investment for both mining and refining but yields superior quality materials essential for advanced industries like semiconductors and optics. Evaluating cost per unit of usable silica content reveals that despite higher initial costs, high-purity quartz offers better long-term economic value in specialized applications.

Sustainability and Environmental Impact of Quartz Mining

Low-grade quartz mining often results in increased environmental degradation due to higher waste production and energy consumption, exacerbating land disturbance and water pollution. High-purity quartz mining, by contrast, employs more precise extraction techniques that minimize ecological footprint and promote resource efficiency, supporting sustainable mineral processing. Innovations in recycling and closed-loop systems are critical in reducing the environmental impact associated with both low-grade and high-purity quartz extraction.

Future Trends in Quartz Purification and Demand

Advancements in quartz purification technologies are driving a significant shift from low-grade quartz towards high-purity quartz in industrial applications, particularly in semiconductor manufacturing and solar panel production. Future trends indicate increasing demand for ultra-pure quartz materials with enhanced optical and electrical properties, fueled by the expansion of renewable energy sectors and electronics industries. Innovations in chemical processing and refining methods are expected to reduce impurities more efficiently, meeting the stringent requirements of next-generation high-tech devices.

Low-Grade Quartz vs High-Purity Quartz Infographic

materialdif.com

materialdif.com