Polymer-bound quartz offers superior durability and flexibility compared to cement-bound quartz, making it ideal for high-traffic areas and environments subject to temperature fluctuations. This composite material resists cracking and staining better due to its resin matrix, providing a longer-lasting and low-maintenance surface. Cement-bound quartz, while more affordable, tends to be more porous and less resistant to wear, requiring more frequent sealing and upkeep.

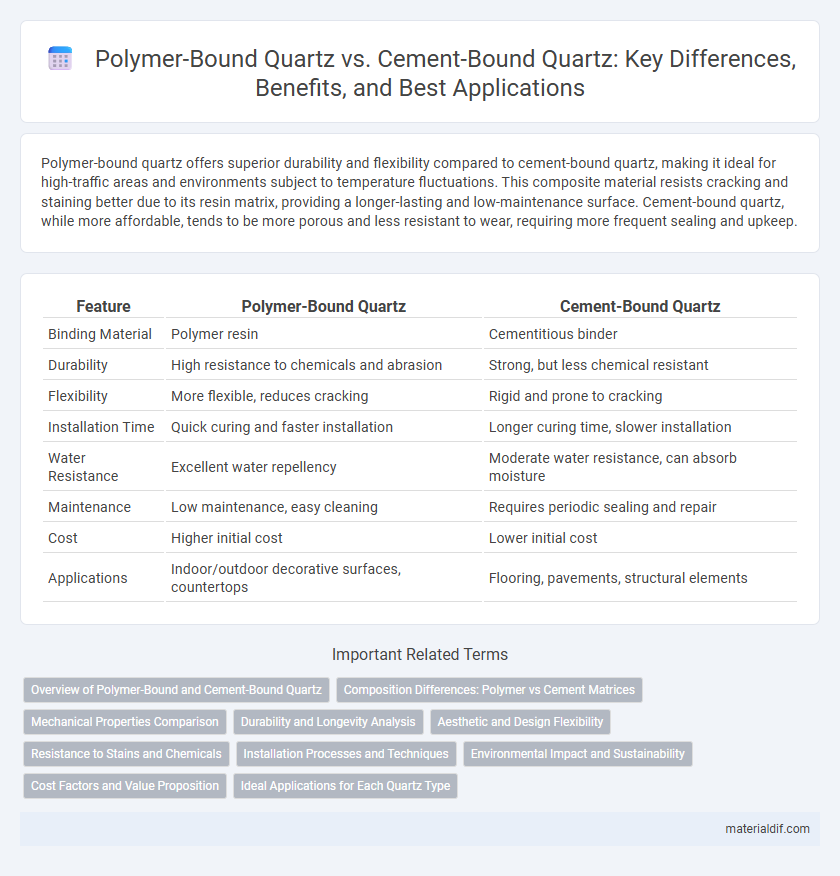

Table of Comparison

| Feature | Polymer-Bound Quartz | Cement-Bound Quartz |

|---|---|---|

| Binding Material | Polymer resin | Cementitious binder |

| Durability | High resistance to chemicals and abrasion | Strong, but less chemical resistant |

| Flexibility | More flexible, reduces cracking | Rigid and prone to cracking |

| Installation Time | Quick curing and faster installation | Longer curing time, slower installation |

| Water Resistance | Excellent water repellency | Moderate water resistance, can absorb moisture |

| Maintenance | Low maintenance, easy cleaning | Requires periodic sealing and repair |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Indoor/outdoor decorative surfaces, countertops | Flooring, pavements, structural elements |

Overview of Polymer-Bound and Cement-Bound Quartz

Polymer-bound quartz consists of high-quality quartz aggregates embedded in a polymer resin matrix, offering enhanced durability, chemical resistance, and flexibility compared to traditional binders. Cement-bound quartz incorporates quartz aggregates within a cementitious matrix, providing excellent compressive strength and structural integrity but with reduced flexibility and increased brittleness. The choice between polymer-bound and cement-bound quartz depends on application requirements, balancing factors such as mechanical performance, environmental resistance, and longevity.

Composition Differences: Polymer vs Cement Matrices

Polymer-bound quartz incorporates synthetic polymer resins as matrices, enhancing flexibility, chemical resistance, and bonding with quartz particles, while cement-bound quartz relies on traditional Portland cement, offering higher compressive strength but lower flexibility. The polymer matrix's organic nature allows superior adhesion and moisture resistance, whereas cement matrices provide rigidity through inorganic hydration processes. These composition differences result in varied performance characteristics suited for distinct industrial and construction applications.

Mechanical Properties Comparison

Polymer-bound quartz exhibits superior mechanical properties compared to cement-bound quartz, including higher tensile strength and enhanced flexural modulus, due to the polymer matrix's ability to better distribute stress and reduce microcracks. Cement-bound quartz typically shows increased brittleness and lower impact resistance, making it less durable under dynamic loading conditions. The improved bonding and elasticity in polymer-bound quartz composites contribute to greater overall mechanical resilience and longevity in structural applications.

Durability and Longevity Analysis

Polymer-bound quartz composites exhibit superior durability and longevity compared to cement-bound quartz due to their enhanced resistance to moisture, chemical degradation, and mechanical stress. The polymer matrix provides a flexible yet robust binding that reduces crack propagation and increases wear resistance, resulting in extended service life. Cement-bound quartz, while cost-effective, is more susceptible to environmental factors like freeze-thaw cycles and alkali-silica reactions, leading to faster material deterioration.

Aesthetic and Design Flexibility

Polymer-bound quartz offers superior aesthetic and design flexibility compared to cement-bound quartz due to its ability to incorporate a wider range of colors, patterns, and finishes. The polymer resin enhances translucency and surface smoothness, resulting in a more uniform and visually appealing appearance. Cement-bound quartz, while durable, tends to have a more limited color palette and a coarser texture that restricts intricate design possibilities.

Resistance to Stains and Chemicals

Polymer-bound quartz exhibits superior resistance to stains and chemicals due to its dense, non-porous surface, which prevents absorption of liquids and corrosive substances. Cement-bound quartz, being more porous, is prone to staining and chemical damage, requiring regular sealing to maintain durability. The enhanced chemical resilience of polymer-bound quartz makes it ideal for high-traffic areas and environments exposed to harsh cleaners or acids.

Installation Processes and Techniques

Polymer-bound quartz installation involves mixing quartz aggregates with a resin binder, allowing for rapid curing and minimal jointing, which enhances surface durability and reduces downtime. Cement-bound quartz requires a traditional wet-mixing process with cement and water, necessitating longer curing periods and precise moisture control to achieve optimal bonding and strength. Techniques for polymer-bound quartz emphasize spray or trowel application with immediate finishing, while cement-bound quartz demands careful formwork and gradual compaction to prevent cracking.

Environmental Impact and Sustainability

Polymer-bound quartz significantly reduces environmental impact by minimizing the need for energy-intensive cement production, which is a major source of CO2 emissions globally. Cement-bound quartz involves higher carbon footprints due to cement manufacturing's heavy use of fossil fuels and raw material extraction, contributing to resource depletion and pollution. Sustainable practices favor polymer binders that offer longer durability and recyclability, thus lowering waste generation and enhancing lifecycle performance.

Cost Factors and Value Proposition

Polymer-bound quartz generally incurs higher upfront costs due to the price of synthetic resins and specialized installation techniques, but it offers superior durability and chemical resistance, reducing maintenance expenses over time. Cement-bound quartz presents a more economical initial investment, leveraging widely available materials and simpler application methods, but may require more frequent repairs and exhibit lower resistance to environmental stress. The value proposition of polymer-bound quartz lies in its long-term performance and minimal upkeep, whereas cement-bound quartz appeals to budget-conscious projects prioritizing affordability over extended lifespan.

Ideal Applications for Each Quartz Type

Polymer-bound quartz offers superior chemical resistance and flexibility, making it ideal for high-performance coatings, decorative surfaces, and applications exposed to frequent mechanical stress or harsh environmental conditions. Cement-bound quartz excels in structural and heavy-duty flooring solutions, providing excellent compressive strength and durability for industrial or commercial environments requiring robust load-bearing capacities. Selecting the appropriate quartz type depends on the specific requirements for mechanical resilience, chemical exposure, and aesthetic finish in the intended application.

Polymer-Bound Quartz vs Cement-Bound Quartz Infographic

materialdif.com

materialdif.com