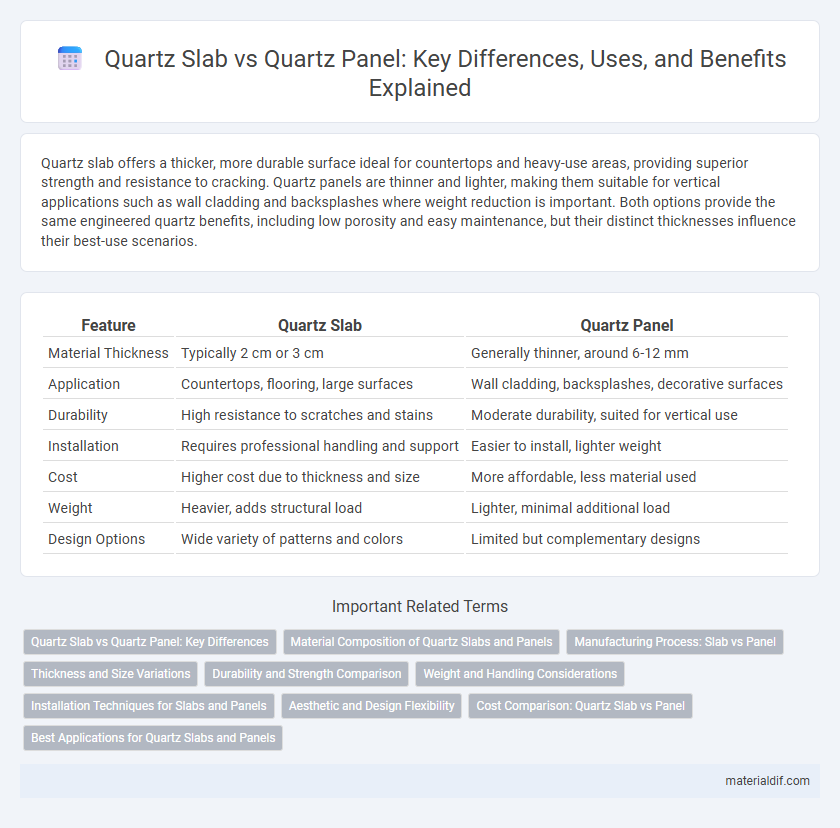

Quartz slab offers a thicker, more durable surface ideal for countertops and heavy-use areas, providing superior strength and resistance to cracking. Quartz panels are thinner and lighter, making them suitable for vertical applications such as wall cladding and backsplashes where weight reduction is important. Both options provide the same engineered quartz benefits, including low porosity and easy maintenance, but their distinct thicknesses influence their best-use scenarios.

Table of Comparison

| Feature | Quartz Slab | Quartz Panel |

|---|---|---|

| Material Thickness | Typically 2 cm or 3 cm | Generally thinner, around 6-12 mm |

| Application | Countertops, flooring, large surfaces | Wall cladding, backsplashes, decorative surfaces |

| Durability | High resistance to scratches and stains | Moderate durability, suited for vertical use |

| Installation | Requires professional handling and support | Easier to install, lighter weight |

| Cost | Higher cost due to thickness and size | More affordable, less material used |

| Weight | Heavier, adds structural load | Lighter, minimal additional load |

| Design Options | Wide variety of patterns and colors | Limited but complementary designs |

Quartz Slab vs Quartz Panel: Key Differences

Quartz slabs are large, thick engineered stone pieces typically used for countertops and flooring, offering durability and a seamless appearance. Quartz panels are thinner, lighter sheets designed for wall cladding and decorative facades, providing flexibility and ease of installation. The primary differences lie in thickness, application, and weight, with slabs suited for horizontal surfaces and panels optimized for vertical surfaces.

Material Composition of Quartz Slabs and Panels

Quartz slabs and quartz panels both consist primarily of engineered quartz, composed of approximately 90-95% natural quartz crystals combined with resins and pigments for enhanced durability and aesthetic appeal. Quartz slabs typically feature a thicker and more homogeneous composition, providing superior strength and resistance to impact and heat. In contrast, quartz panels are generally thinner, optimized for decorative applications where flexibility and lighter weight are essential, but they maintain a similar base material composition to slabs.

Manufacturing Process: Slab vs Panel

Quartz slabs are manufactured by compacting quartz crystals with resins and pigments under high pressure and heat, resulting in large, uniform surfaces ideal for countertops and flooring. Quartz panels undergo a similar process but are produced with thinner layers, designed for wall cladding and decorative architectural applications. The primary difference in manufacturing lies in the compression techniques and curing times, which influence thickness, durability, and intended use.

Thickness and Size Variations

Quartz slabs typically measure between 2 cm and 3 cm in thickness, offering robust durability for countertops and flooring applications, while quartz panels are generally thinner, ranging from 6 mm to 12 mm, suited for wall cladding and decorative purposes. Size variations in quartz slabs can reach up to 120 inches by 55 inches, providing expansive surface coverage, whereas quartz panels usually come in smaller dimensions, such as 48 inches by 96 inches, allowing for easier handling and installation. These differences in thickness and size directly affect the material's load-bearing capacity, aesthetic appeal, and versatility across residential and commercial design projects.

Durability and Strength Comparison

Quartz slabs offer superior durability due to their thickness, typically ranging from 2 cm to 3 cm, providing enhanced resistance to impact and heavy use. Quartz panels, thinner at around 6 mm to 12 mm, are more prone to bending and chipping, making slabs a stronger choice for countertops and high-traffic surfaces. The engineered composition of quartz slabs also contributes to their robustness, maintaining strength and resistance to heat and scratches better than quartz panels.

Weight and Handling Considerations

Quartz slabs, typically measuring 120 to 130 pounds per square foot, are heavier than quartz panels, which often weigh around 50 to 60 pounds per panel due to their thinner profile. The substantial weight of quartz slabs requires careful handling, usually necessitating specialized equipment and skilled labor to prevent damage during installation. Quartz panels offer easier maneuverability and faster installation, making them ideal for vertical applications where weight and ease of handling are critical factors.

Installation Techniques for Slabs and Panels

Quartz slab installation requires precise handling due to its large, heavy dimensions, often necessitating professional equipment like suction cups and leveling tools to ensure a seamless fit on countertops and flooring. Quartz panels, being thinner and lighter, allow for more flexible installation techniques, including adhesive bonding directly to vertical surfaces or frameworks, making them ideal for wall cladding and decorative facades. Both slabs and panels demand meticulous surface preparation and consistent curing times for adhesives or mortar to guarantee durability and longevity in applications.

Aesthetic and Design Flexibility

Quartz slabs provide a seamless, large-format surface ideal for countertops and backsplashes, offering sleek, uniform aesthetics with minimal grout lines. Quartz panels, typically thinner and smaller, allow for intricate design applications such as wall claddings, cabinetry, and decorative accents, enhancing spatial creativity. Both options deliver durable, customizable surfaces with diverse color and pattern variations, catering to varied aesthetic preferences and architectural needs.

Cost Comparison: Quartz Slab vs Panel

Quartz slabs generally cost more than quartz panels due to their larger size, higher material volume, and increased fabrication requirements. Quartz panels, being thinner and prefabricated, offer a more budget-friendly option while maintaining durability and aesthetic appeal. Choosing between quartz slab and quartz panel primarily depends on the project's scale, budget constraints, and desired finish quality.

Best Applications for Quartz Slabs and Panels

Quartz slabs, with their large size and uniform thickness, are ideal for kitchen countertops, bathroom vanities, and large-scale wall cladding where seamless surface and durability are essential. Quartz panels, typically thinner and lighter, are best suited for decorative wall applications, backsplashes, and furniture facades that require easy installation and precise cutouts. Both quartz slabs and panels provide scratch resistance, low maintenance, and a wide range of patterns, but slabs offer superior structural integrity for heavy-use surfaces.

Quartz Slab vs Quartz Panel Infographic

materialdif.com

materialdif.com