Quartz slabs offer natural stone aesthetics with durability and low maintenance, while porcelain slabs provide superior resistance to heat, scratches, and stains due to their dense, non-porous composition. Porcelain slabs are ideal for both indoor and outdoor applications, boasting high resistance to UV rays and weathering, whereas quartz slabs are primarily preferred for indoor countertops and surfaces. Choosing between quartz and porcelain slabs depends on specific needs like durability, aesthetics, and environmental exposure.

Table of Comparison

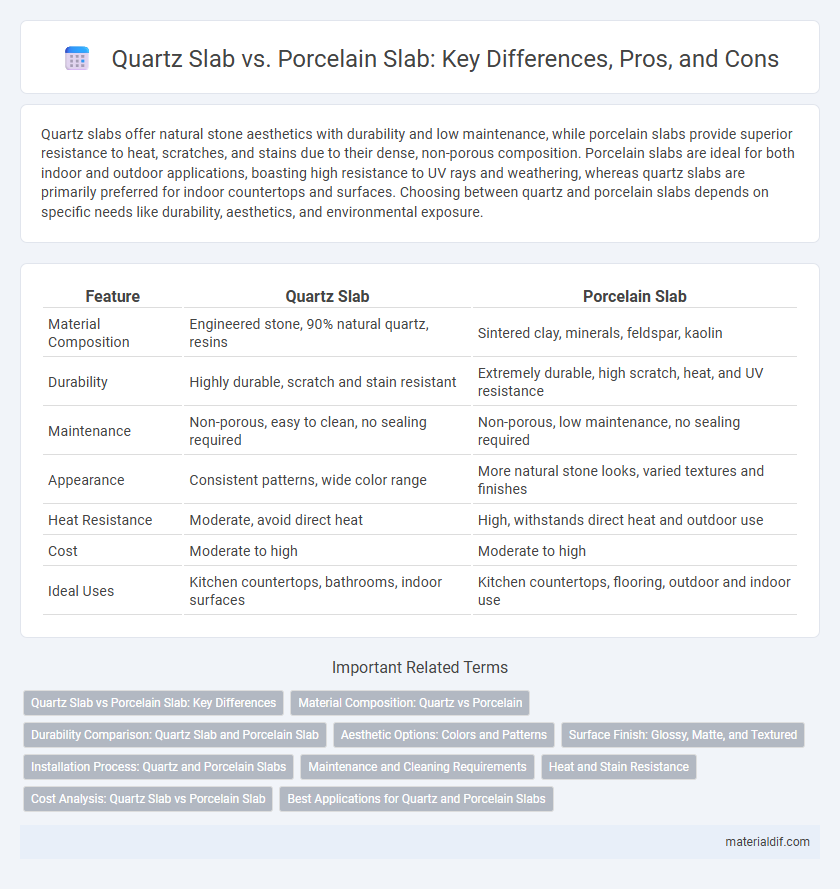

| Feature | Quartz Slab | Porcelain Slab |

|---|---|---|

| Material Composition | Engineered stone, 90% natural quartz, resins | Sintered clay, minerals, feldspar, kaolin |

| Durability | Highly durable, scratch and stain resistant | Extremely durable, high scratch, heat, and UV resistance |

| Maintenance | Non-porous, easy to clean, no sealing required | Non-porous, low maintenance, no sealing required |

| Appearance | Consistent patterns, wide color range | More natural stone looks, varied textures and finishes |

| Heat Resistance | Moderate, avoid direct heat | High, withstands direct heat and outdoor use |

| Cost | Moderate to high | Moderate to high |

| Ideal Uses | Kitchen countertops, bathrooms, indoor surfaces | Kitchen countertops, flooring, outdoor and indoor use |

Quartz Slab vs Porcelain Slab: Key Differences

Quartz slabs offer non-porous surfaces with enhanced durability and resistance to stains due to their engineered composition of natural quartz and resins. Porcelain slabs, made from dense ceramic materials fired at high temperatures, provide superior heat and scratch resistance along with low water absorption. Key differences include quartz slabs' warmth and variety of patterns versus porcelain slabs' lightweight, UV resistance, and suitability for both indoor and outdoor applications.

Material Composition: Quartz vs Porcelain

Quartz slabs consist of approximately 90% natural quartz crystals combined with resin binders and pigments, offering exceptional hardness and non-porous surface properties. Porcelain slabs are made from a blend of natural clay, sand, and feldspar, fired at extremely high temperatures to achieve density and durability with minimal water absorption. The intrinsic material composition of quartz provides enhanced resistance to stains and scratches, while porcelain's vitrified structure grants superior heat resistance and structural rigidity.

Durability Comparison: Quartz Slab and Porcelain Slab

Quartz slabs exhibit high durability with excellent resistance to scratches, stains, and heat, making them ideal for heavy-use kitchen countertops. Porcelain slabs offer superior hardness and are highly resistant to UV rays, making them more suitable for outdoor applications and environments prone to high temperatures. Both materials provide long-lasting performance, but porcelain's enhanced durability against weathering and heat surpasses that of quartz in specific use cases.

Aesthetic Options: Colors and Patterns

Quartz slabs offer a wide range of colors and patterns, including natural stone looks and vibrant, uniform hues due to engineered manufacturing. Porcelain slabs provide exceptional variety with intricate designs that can mimic marble, wood, and concrete, often featuring high-resolution prints and a naturally textured surface. Both materials excel in aesthetic versatility, but porcelain typically allows for larger slab sizes and more detailed pattern replication.

Surface Finish: Glossy, Matte, and Textured

Quartz slabs offer a range of surface finishes including glossy, matte, and textured, each enhancing aesthetic appeal and functionality depending on the application. Porcelain slabs also provide similar finishes but tend to be more resistant to scratches and stains, especially in glossy forms, while textured porcelain surfaces offer superior slip resistance compared to quartz. The choice between quartz and porcelain slabs with respect to surface finish hinges on desired durability, maintenance level, and design preference for residential or commercial spaces.

Installation Process: Quartz and Porcelain Slabs

Quartz slabs require professional installation due to their weight and resin composition, typically involving precise cutting with diamond blades and adhesive bonding to ensure durability. Porcelain slabs demand specialized tools like water-cooled diamond saws for cutting and are often installed with epoxy or thin-set mortar, requiring careful handling to prevent chipping. Both materials benefit from experienced fabricators to achieve clean edges and seamless fitting, but porcelain's brittleness makes its installation process more delicate compared to quartz.

Maintenance and Cleaning Requirements

Quartz slabs require regular cleaning with mild detergent and water to maintain their non-porous surface, preventing staining and bacterial growth, while avoiding harsh chemicals or abrasive pads. Porcelain slabs are highly resistant to stains and scratches, allowing for easy maintenance with just soap and water, and they do not require sealing over time. Both materials offer low-maintenance solutions, but quartz may need periodic sealing to preserve its appearance depending on the specific resin used.

Heat and Stain Resistance

Quartz slabs exhibit excellent stain resistance due to their non-porous surface, making them highly durable against common household stains. However, quartz is sensitive to heat and can suffer damage or discoloration when exposed to high temperatures. Porcelain slabs, in contrast, offer superior heat resistance and maintain their structural integrity under intense heat, while also providing strong stain resistance suitable for kitchen and outdoor applications.

Cost Analysis: Quartz Slab vs Porcelain Slab

Quartz slabs typically range from $50 to $150 per square foot, making them a premium choice compared to porcelain slabs, which generally cost between $30 and $70 per square foot. The installation costs for quartz are often higher due to its heavier weight and the need for professional handling, whereas porcelain slabs are lighter and easier to install, reducing labor expenses. Maintenance costs favor porcelain as well since it is more resistant to staining and chipping, lowering the need for repairs over time.

Best Applications for Quartz and Porcelain Slabs

Quartz slabs are ideal for kitchen countertops and bathroom vanities due to their non-porous surface, resistance to stains, and wide range of colors and patterns. Porcelain slabs excel in outdoor applications, commercial spaces, and high-traffic areas because of their superior durability, heat resistance, and low maintenance requirements. Both materials offer versatility but quartz suits indoor environments requiring aesthetic appeal, while porcelain fits demanding settings needing robust performance.

Quartz Slab vs Porcelain Slab Infographic

materialdif.com

materialdif.com