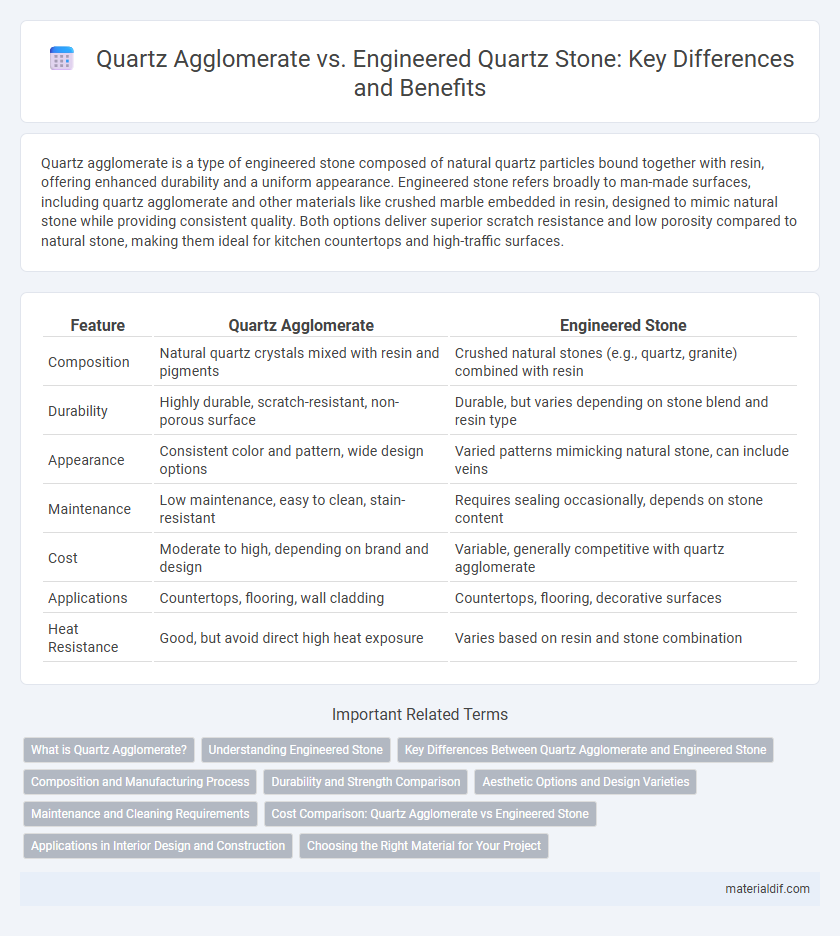

Quartz agglomerate is a type of engineered stone composed of natural quartz particles bound together with resin, offering enhanced durability and a uniform appearance. Engineered stone refers broadly to man-made surfaces, including quartz agglomerate and other materials like crushed marble embedded in resin, designed to mimic natural stone while providing consistent quality. Both options deliver superior scratch resistance and low porosity compared to natural stone, making them ideal for kitchen countertops and high-traffic surfaces.

Table of Comparison

| Feature | Quartz Agglomerate | Engineered Stone |

|---|---|---|

| Composition | Natural quartz crystals mixed with resin and pigments | Crushed natural stones (e.g., quartz, granite) combined with resin |

| Durability | Highly durable, scratch-resistant, non-porous surface | Durable, but varies depending on stone blend and resin type |

| Appearance | Consistent color and pattern, wide design options | Varied patterns mimicking natural stone, can include veins |

| Maintenance | Low maintenance, easy to clean, stain-resistant | Requires sealing occasionally, depends on stone content |

| Cost | Moderate to high, depending on brand and design | Variable, generally competitive with quartz agglomerate |

| Applications | Countertops, flooring, wall cladding | Countertops, flooring, decorative surfaces |

| Heat Resistance | Good, but avoid direct high heat exposure | Varies based on resin and stone combination |

What is Quartz Agglomerate?

Quartz agglomerate is a composite material consisting of roughly 90-95% natural quartz crystals combined with resin binders and pigments to create a dense, durable surface. Unlike engineered stone, which often includes a mix of quartz and other aggregates, quartz agglomerate emphasizes a higher quartz content for enhanced hardness and resistance to scratches. This material is commonly used in kitchen countertops and flooring due to its durability, low porosity, and aesthetic appeal.

Understanding Engineered Stone

Engineered stone is a composite material manufactured by combining natural quartz particles with resin binders and pigments, delivering a highly durable and non-porous surface ideal for countertops and flooring. Unlike quartz agglomerate, which primarily consists of crushed quartz without extensive binding agents, engineered stone offers enhanced consistency in color and texture due to its controlled production process. Its resistance to stains, scratches, and heat makes engineered stone a popular choice for both residential and commercial applications.

Key Differences Between Quartz Agglomerate and Engineered Stone

Quartz agglomerate consists of natural quartz fragments bonded with resin, offering high durability and resistance to heat and scratches, making it ideal for countertops. Engineered stone, while similar in composition, may incorporate additional fillers and pigments, allowing for a wider range of colors and patterns but sometimes sacrificing slightly on hardness and heat resistance. The key differences lie in their manufacturing process, material composition, and resulting physical properties, which influence cost, appearance, and performance in various applications.

Composition and Manufacturing Process

Quartz agglomerate consists predominantly of natural quartz crystals bound together by resin, whereas engineered stone combines quartz with other minerals and polymers for enhanced durability. The manufacturing process of quartz agglomerate involves compressing and curing quartz resin mixtures under heat and pressure, while engineered stone is typically produced by blending crushed stone with resins and pigments, then casting and curing the composite. Both methods result in non-porous, stain-resistant surfaces but differ in ingredient ratios and production techniques affecting strength and appearance.

Durability and Strength Comparison

Quartz agglomerate comprises crushed quartz bound with resin, offering high durability and moderate strength suitable for residential use. Engineered stone, typically made of natural quartz with enhanced polymer binders, provides superior strength and resistance to impact and staining, ideal for commercial applications. Both materials exhibit low porosity, ensuring excellent scratch and heat resistance, but engineered stone generally outperforms quartz agglomerate in long-term durability under heavy use.

Aesthetic Options and Design Varieties

Quartz agglomerate offers a broad range of aesthetic options, featuring vibrant colors and natural stone patterns created by binding crushed quartz with resin. Engineered stone also provides extensive design variety, often mimicking natural stones like marble and granite with enhanced durability and uniformity. Both materials excel in delivering customizable styles suited for modern countertops, backsplashes, and flooring applications.

Maintenance and Cleaning Requirements

Quartz agglomerate requires regular cleaning with mild soap and water to maintain its non-porous surface and prevent staining, while engineered stone demands similar care but may need specialized cleaners to protect its resin and pigments. Both materials resist scratches and heat but should avoid harsh chemicals and abrasive pads to preserve their finishes. Routine maintenance for both involves wiping spills promptly and periodic sealing for certain engineered stone variants to enhance durability.

Cost Comparison: Quartz Agglomerate vs Engineered Stone

Quartz agglomerate typically costs less than engineered stone due to its simpler manufacturing process and lower material expenses. Engineered stone, infused with resin and compacted under high pressure, often demands higher production costs reflected in its market price. Choosing between the two depends on budget constraints and desired durability, with quartz agglomerate offering a cost-effective option without sacrificing performance.

Applications in Interior Design and Construction

Quartz agglomerate and engineered stone serve distinct roles in interior design and construction, with quartz agglomerate favored for its natural quartz content offering superior durability and scratch resistance in high-traffic areas like kitchen countertops and flooring. Engineered stone, composed of crushed stone bound with resin, provides versatile aesthetic options and is commonly used for bathroom vanities, wall claddings, and decorative accents due to its customizable surface finishes. Both materials enhance interior aesthetics while providing functional benefits such as low porosity and ease of maintenance, making them ideal choices in residential and commercial projects.

Choosing the Right Material for Your Project

Quartz agglomerate offers durability and consistent color patterns ideal for high-traffic surfaces, while engineered stone provides a wider variety of design options with added flexibility in thickness and texture. Consider the project's specific requirements such as budget, aesthetic preferences, and maintenance needs to determine the most suitable material. Evaluating factors like stain resistance, heat tolerance, and installation complexity ensures an informed choice for kitchens, bathrooms, or commercial spaces.

Quartz Agglomerate vs Engineered Stone Infographic

materialdif.com

materialdif.com