Porcelain and quartz are both popular materials for countertops, but they differ significantly in composition and properties. Porcelain is a ceramic made from clay and minerals, fired at high temperatures to achieve durability and resistance to scratches, stains, and heat, making it ideal for outdoor and indoor use. Quartz, an engineered stone composed of natural quartz crystals mixed with resins, offers exceptional strength, low porosity, and a wide range of colors and patterns, making it highly resistant to stains and easy to maintain.

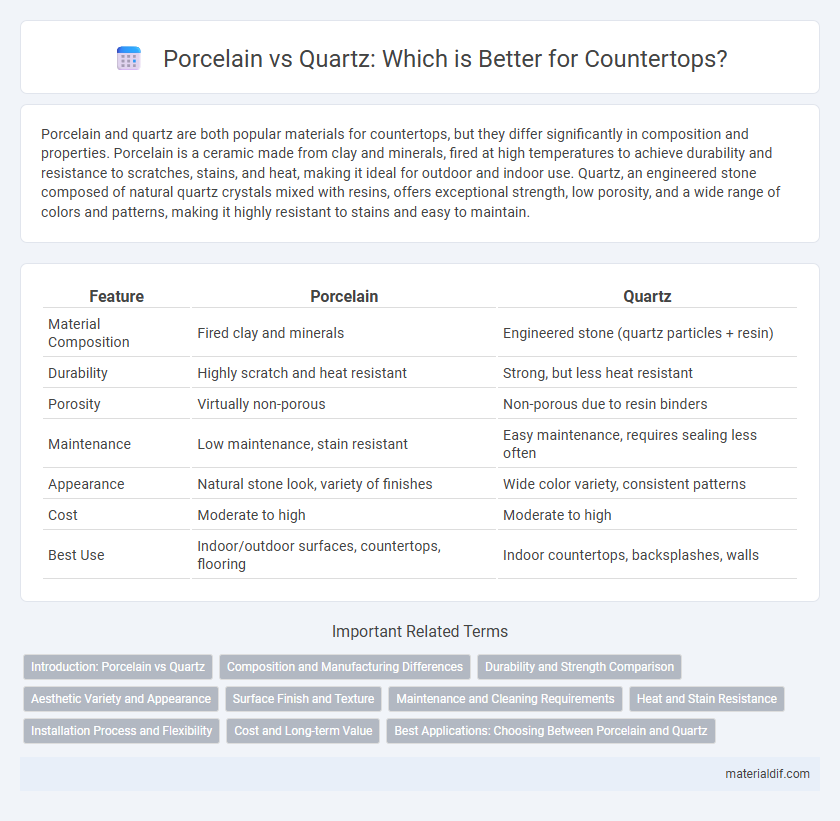

Table of Comparison

| Feature | Porcelain | Quartz |

|---|---|---|

| Material Composition | Fired clay and minerals | Engineered stone (quartz particles + resin) |

| Durability | Highly scratch and heat resistant | Strong, but less heat resistant |

| Porosity | Virtually non-porous | Non-porous due to resin binders |

| Maintenance | Low maintenance, stain resistant | Easy maintenance, requires sealing less often |

| Appearance | Natural stone look, variety of finishes | Wide color variety, consistent patterns |

| Cost | Moderate to high | Moderate to high |

| Best Use | Indoor/outdoor surfaces, countertops, flooring | Indoor countertops, backsplashes, walls |

Introduction: Porcelain vs Quartz

Porcelain and quartz are two prominent materials used in countertop and flooring applications, each offering distinct properties and benefits. Porcelain is a ceramic material known for its durability, resistance to heat, and ultra-low porosity, making it highly stain-resistant. Quartz, an engineered stone composed of natural quartz crystals combined with resin, provides exceptional strength, non-porosity, and a wide range of aesthetic options ideal for kitchens and bathrooms.

Composition and Manufacturing Differences

Porcelain is made from natural clay and minerals fired at extremely high temperatures to achieve a dense, non-porous surface, while quartz countertops consist of around 90% engineered quartz crystals combined with resin and pigments for durability and design variety. The manufacturing of porcelain involves a sintering process, which fuses materials without melting them, ensuring hardness and heat resistance. Quartz countertops are produced through a process called compression molding, which binds crushed quartz with resin, offering enhanced flexibility and stain resistance.

Durability and Strength Comparison

Porcelain and quartz both exhibit exceptional durability, but quartz is engineered with resin binders and natural quartz crystals, resulting in higher scratch and impact resistance. Porcelain is highly heat resistant and less prone to staining due to its vitrified surface, yet quartz surfaces generally surpass porcelain in tensile strength and overall toughness. For applications demanding long-term strength and minimal maintenance, quartz is often the preferred choice due to its superior durability under heavy usage conditions.

Aesthetic Variety and Appearance

Quartz offers a broader aesthetic variety with over 90% natural quartz crystals combined with pigments and resins, allowing for consistent colors and patterns that mimic natural stones like marble and granite. Porcelain, while durable and available in various finishes, often has a more limited range of colors and textures, typically embodying a matte or glossy tile appearance. Quartz surfaces provide a seamless, polished look with customizable options, making them ideal for modern, elegant interior designs where uniformity and gloss are desired.

Surface Finish and Texture

Porcelain surfaces exhibit a smooth, matte finish with subtle texture variations that enhance their natural stone appearance, making them highly resistant to scratches and staining. Quartz countertops, engineered from natural quartz crystals combined with resins, offer a glossy or semi-glossy finish with a consistently uniform texture that provides enhanced durability and low maintenance. Both materials deliver impressive surface resilience, but porcelain's denser composition results in a slightly cooler, harder feel compared to the warmer, more polished texture of quartz.

Maintenance and Cleaning Requirements

Porcelain surfaces require minimal maintenance, needing only regular cleaning with mild soap and water to prevent stains and preserve their natural finish. Quartz countertops are non-porous and resistant to staining but should be cleaned with a gentle, non-abrasive cleaner to avoid dulling their polished surface. Both materials avoid sealing, but quartz demands careful attention to avoid harsh chemicals that can degrade resin binders.

Heat and Stain Resistance

Quartz surfaces offer superior stain resistance compared to porcelain due to their non-porous structure, which prevents liquids and oils from penetrating. Porcelain's heat resistance is notably higher, withstanding direct exposure to high temperatures without damage, making it ideal for kitchen applications involving hot pots and pans. Quartz can tolerate moderate heat but risks discoloration or damage when exposed to extreme temperatures.

Installation Process and Flexibility

Porcelain tiles require a more intricate installation process involving precise cutting and specialized tools due to their hardness and brittleness, making adjustments on-site challenging. In contrast, quartz slabs offer greater flexibility with simpler installation techniques, allowing for easier customization and quicker fitting, especially on countertops and complex layouts. Quartz's adaptability reduces labor time and potential damage, providing a more efficient solution in dynamic spaces.

Cost and Long-term Value

Porcelain typically costs less upfront than quartz, making it an attractive option for budget-conscious projects. Quartz offers superior durability and low maintenance, which enhances long-term value by reducing replacement and repair expenses. Investing in quartz surfaces often results in higher overall cost efficiency due to its resilience and sustained aesthetic appeal.

Best Applications: Choosing Between Porcelain and Quartz

Porcelain excels in outdoor applications and high-traffic areas due to its durability, resistance to UV rays, and low porosity, making it ideal for patios, facades, and bathrooms. Quartz's engineered surface offers superior scratch resistance and non-porosity, perfect for kitchen countertops and indoor surfaces requiring easy maintenance and stain resistance. Selecting between porcelain and quartz depends on the specific environment and usage, with porcelain favored for exterior and heavy-wear areas, while quartz suits indoor settings demanding elegance and hygiene.

Porcelain vs Quartz Infographic

materialdif.com

materialdif.com