Quartz surfaces offer enhanced durability and stain resistance compared to solid surfaces, making them ideal for high-traffic areas like kitchens and bathrooms. Unlike solid surfaces, quartz countertops are engineered from natural quartz crystals bound with resin, providing superior hardness and scratch resistance. Maintenance is minimal since quartz does not require sealing, unlike many solid surface materials that can be more porous and prone to damage.

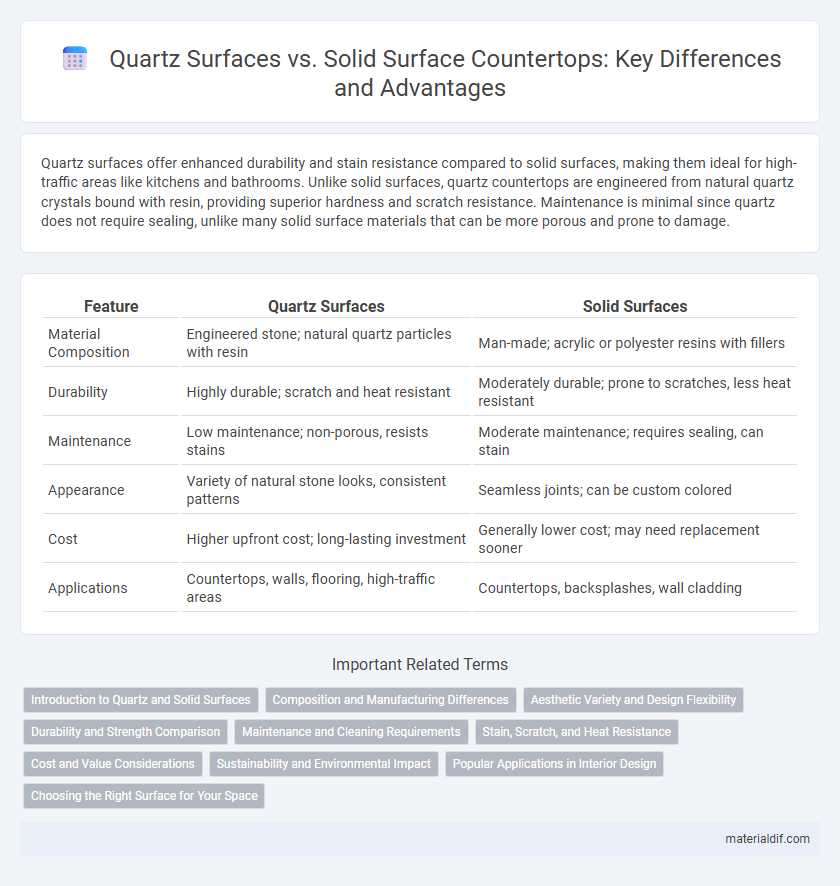

Table of Comparison

| Feature | Quartz Surfaces | Solid Surfaces |

|---|---|---|

| Material Composition | Engineered stone; natural quartz particles with resin | Man-made; acrylic or polyester resins with fillers |

| Durability | Highly durable; scratch and heat resistant | Moderately durable; prone to scratches, less heat resistant |

| Maintenance | Low maintenance; non-porous, resists stains | Moderate maintenance; requires sealing, can stain |

| Appearance | Variety of natural stone looks, consistent patterns | Seamless joints; can be custom colored |

| Cost | Higher upfront cost; long-lasting investment | Generally lower cost; may need replacement sooner |

| Applications | Countertops, walls, flooring, high-traffic areas | Countertops, backsplashes, wall cladding |

Introduction to Quartz and Solid Surfaces

Quartz surfaces consist of engineered stone made primarily from natural quartz crystals combined with resin and pigments, offering high durability, non-porous characteristics, and resistance to stains and scratches. Solid surfaces are man-made materials composed of acrylic, polyester, or a blend of resins and alumina trihydrate, known for their seamless appearance, repairability, and ease of maintenance. Both materials provide versatile applications in countertops and interior design but differ in composition, performance, and aesthetic appeal.

Composition and Manufacturing Differences

Quartz surfaces consist of approximately 90-95% natural quartz crystals combined with resin and pigments, offering enhanced durability and non-porosity. Solid surfaces are primarily made from acrylic or polyester resins mixed with minerals and pigments, resulting in a non-porous, seamless finish that can be more easily repaired. The manufacturing process for quartz involves engineered compression under heat and pressure, whereas solid surfaces are typically cast or poured and then cured.

Aesthetic Variety and Design Flexibility

Quartz surfaces offer a broader aesthetic variety compared to solid surfaces due to their engineered composition, allowing for consistent patterns and a wide range of colors that mimic natural stone with enhanced durability. Solid surfaces provide seamless joints and can be easily shaped into various designs, granting exceptional design flexibility for custom installations and integrated sinks. The combination of quartz's visual diversity and solid surfaces' moldability ensures tailored options for both modern and traditional interior designs.

Durability and Strength Comparison

Quartz surfaces exhibit superior durability and strength compared to solid surfaces due to their engineered composition of natural quartz combined with resins. The non-porous nature of quartz makes it highly resistant to scratches, stains, and heat, outperforming many solid surface materials. Solid surfaces, while resilient, generally lack the hardness of quartz, making them more prone to dents and surface damage over time.

Maintenance and Cleaning Requirements

Quartz surfaces feature non-porous construction, making them highly resistant to staining and requiring minimal maintenance compared to solid surfaces, which may absorb liquids and need more frequent sealing. Cleaning quartz involves simple wiping with mild soap and water, avoiding harsh chemicals to preserve its finish. Solid surfaces typically need periodic resealing and gentle cleaners to prevent damage and maintain appearance over time.

Stain, Scratch, and Heat Resistance

Quartz surfaces exhibit superior stain resistance due to their non-porous, engineered composition, preventing absorption of liquids and making them easier to maintain. Solid surfaces, while generally resistant to scratches, may show wear over time compared to quartz's tougher, silica-based structure that enhances scratch durability. Heat resistance is stronger in quartz surfaces, withstanding higher temperatures without damage, whereas solid surfaces can be more vulnerable to heat-induced marks and warping.

Cost and Value Considerations

Quartz surfaces typically cost between $50 and $150 per square foot, offering a durable and low-maintenance option with high resistance to stains and scratches. Solid surfaces, priced around $40 to $100 per square foot, provide seamless installation and easy repairability but may be more prone to heat damage and scratching. Evaluating long-term value, quartz often delivers better durability and resale appeal despite its higher upfront cost compared to solid surfaces.

Sustainability and Environmental Impact

Quartz surfaces are engineered using natural quartz crystals combined with resins and pigments, resulting in non-porous, durable materials that typically emit lower VOCs compared to some solid surfaces made from synthetic or composite materials. The manufacturing process of quartz surfaces often incorporates waste recycling and energy-efficient technologies, enhancing sustainability by reducing landfill contributions and resource consumption. In contrast, certain solid surfaces may rely heavily on petroleum-based resins or require more intensive energy during production, potentially increasing their environmental footprint.

Popular Applications in Interior Design

Quartz surfaces, engineered from natural quartz crystals combined with resins and pigments, offer exceptional durability and low maintenance, making them popular for kitchen countertops, bathroom vanities, and backsplashes. Solid surfaces, composed of acrylic or polyester resins with mineral fillers, are favored for seamless integration in sinks, wall cladding, and curved surfaces due to their non-porous and repairable nature. Both materials are widely used in interior design, with quartz preferred for high-traffic areas requiring scratch and stain resistance, while solid surfaces excel in customized, smooth, and hygienic applications.

Choosing the Right Surface for Your Space

Quartz surfaces offer unmatched durability and stain resistance due to their engineered composition of natural quartz crystals mixed with resins, making them ideal for high-traffic kitchens and bathrooms. Solid surfaces, crafted from acrylic or polyester resins, provide seamless joints and easy repair options, perfect for customized designs and integrating sinks or backsplashes. Selecting between quartz and solid surfaces depends on balancing the need for hardness and low maintenance with flexibility in design and repairability to enhance the functionality and aesthetics of your space.

Quartz Surfaces vs Solid Surfaces Infographic

materialdif.com

materialdif.com