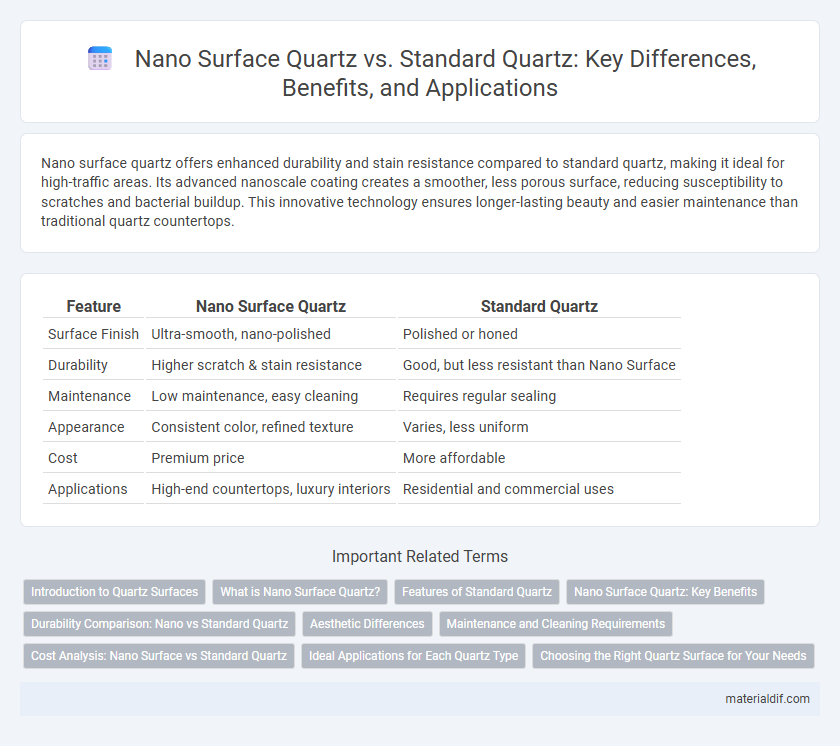

Nano surface quartz offers enhanced durability and stain resistance compared to standard quartz, making it ideal for high-traffic areas. Its advanced nanoscale coating creates a smoother, less porous surface, reducing susceptibility to scratches and bacterial buildup. This innovative technology ensures longer-lasting beauty and easier maintenance than traditional quartz countertops.

Table of Comparison

| Feature | Nano Surface Quartz | Standard Quartz |

|---|---|---|

| Surface Finish | Ultra-smooth, nano-polished | Polished or honed |

| Durability | Higher scratch & stain resistance | Good, but less resistant than Nano Surface |

| Maintenance | Low maintenance, easy cleaning | Requires regular sealing |

| Appearance | Consistent color, refined texture | Varies, less uniform |

| Cost | Premium price | More affordable |

| Applications | High-end countertops, luxury interiors | Residential and commercial uses |

Introduction to Quartz Surfaces

Quartz surfaces, composed of approximately 90-95% natural quartz crystals combined with resins and pigments, offer exceptional durability and scratch resistance compared to standard surfaces. Nano Surface Quartz incorporates advanced nanotechnology, enhancing stain resistance and providing a smoother, more non-porous finish than traditional quartz, making it ideal for high-use areas. Both types maintain quartz's inherent hardness and low maintenance, but Nano Surface Quartz delivers superior performance in hygiene and longevity.

What is Nano Surface Quartz?

Nano Surface Quartz is an advanced engineered stone featuring ultra-fine quartz particles combined with nanotechnology to create a highly durable and non-porous surface. This innovation enhances resistance to scratches, stains, and heat compared to standard quartz, making it ideal for high-traffic kitchens and bathrooms. Its smooth, glossy finish also provides superior aesthetic appeal and easier maintenance over traditional quartz surfaces.

Features of Standard Quartz

Standard quartz surfaces offer high durability with excellent resistance to scratches, stains, and heat, making them ideal for kitchen countertops and heavy-use areas. They also provide a non-porous surface that inhibits bacterial growth and requires minimal maintenance compared to natural stones. Standard quartz is available in a wide range of colors and patterns, ensuring versatile design options for both residential and commercial applications.

Nano Surface Quartz: Key Benefits

Nano Surface Quartz offers superior durability compared to standard quartz, featuring enhanced resistance to scratches, stains, and heat due to its advanced nano-coating technology. This innovative surface provides a non-porous, hygienic barrier that prevents bacterial growth and simplifies cleaning, making it ideal for high-traffic areas. Its consistent color retention and low maintenance requirements position Nano Surface Quartz as a premium choice for long-lasting, aesthetically appealing countertops.

Durability Comparison: Nano vs Standard Quartz

Nano Surface Quartz exhibits superior durability compared to standard quartz due to its enhanced resistance to scratches, stains, and impact. The nanotechnology used in its production creates a denser and more uniform surface, significantly reducing porosity and increasing hardness. This results in longer-lasting performance and lower maintenance requirements compared to conventional quartz materials.

Aesthetic Differences

Nano surface quartz offers a smoother, more refined finish compared to standard quartz, resulting in enhanced light reflection and a visually striking appearance. The ultra-fine texture of nano surface quartz provides a modern, sleek look with deeper color richness and subtle depth. Standard quartz, while durable, typically features a slightly coarser texture and less pronounced color vibrancy, making nano surface quartz preferable for high-end design applications focused on aesthetic sophistication.

Maintenance and Cleaning Requirements

Nano Surface Quartz requires minimal maintenance due to its enhanced non-porous structure, which resists stains and fingerprints more effectively than Standard Quartz. Standard Quartz, while durable, often needs more frequent cleaning with mild soap and avoids abrasive cleaners to prevent surface dullness. Both materials benefit from wiping spills promptly, but Nano Surface Quartz offers superior long-term ease of cleaning and upkeep.

Cost Analysis: Nano Surface vs Standard Quartz

Nano Surface Quartz typically commands a higher price point than Standard Quartz due to its advanced manufacturing process and enhanced durability. The cost difference ranges from 15% to 30%, reflecting the premium nature of nano-coating technology that improves scratch resistance and stain protection. Despite the initial investment, Nano Surface Quartz offers long-term savings by reducing maintenance and replacement expenses associated with Standard Quartz.

Ideal Applications for Each Quartz Type

Nano Surface Quartz, known for its ultra-smooth texture and enhanced resistance to stains and scratches, is ideal for high-traffic areas such as kitchen countertops, commercial surfaces, and bathroom vanities where durability and cleanliness are paramount. Standard Quartz, offering a balanced combination of strength and affordability, suits applications like wall cladding, less frequently used countertops, and decorative partitions where moderate wear is expected. Selecting the appropriate quartz type maximizes longevity and aesthetic appeal based on specific usage demands and environmental conditions.

Choosing the Right Quartz Surface for Your Needs

Nano surface quartz offers enhanced scratch resistance and a smoother finish compared to standard quartz, making it ideal for high-traffic areas and heavy-use countertops. Standard quartz provides durability and a wide range of colors at a more affordable price point, suitable for general home applications. Selecting the right quartz surface depends on balancing budget constraints, usage intensity, and desired aesthetic appeal for your space.

Nano Surface Quartz vs Standard Quartz Infographic

materialdif.com

materialdif.com