Quartz crystal is a naturally occurring mineral known for its unique piezoelectric properties and exceptional durability, making it highly valuable in watches, electronics, and healing practices. Quartz glass, on the other hand, is a synthetic material produced by melting high-purity silica, prized for its transparency, thermal resistance, and use in optical instruments and laboratory equipment. Both materials share the same chemical composition of silicon dioxide but differ significantly in structure, formation, and applications.

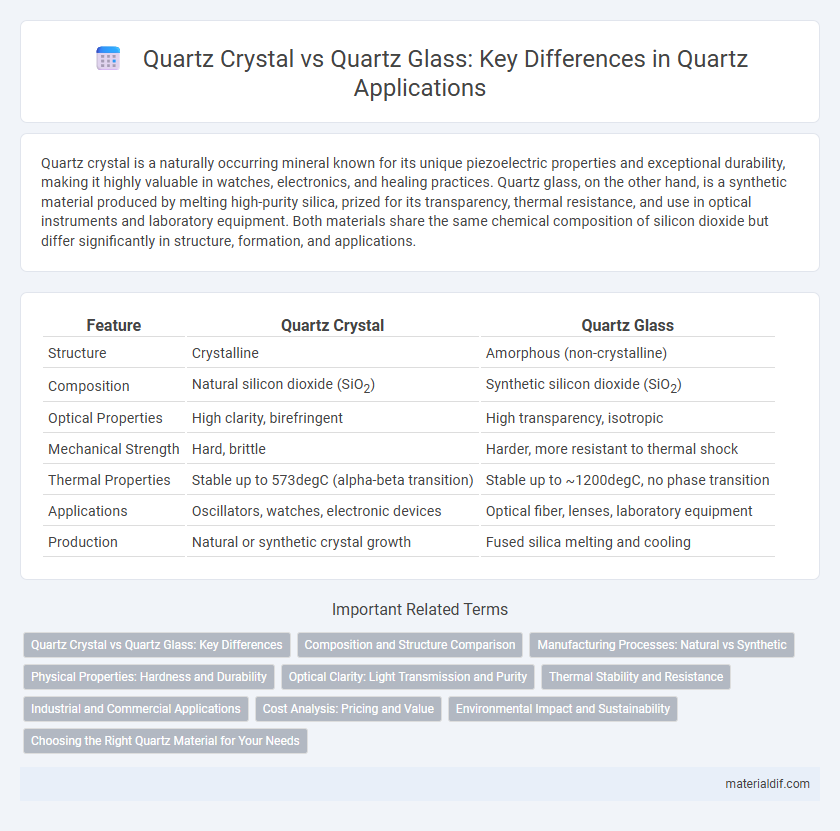

Table of Comparison

| Feature | Quartz Crystal | Quartz Glass |

|---|---|---|

| Structure | Crystalline | Amorphous (non-crystalline) |

| Composition | Natural silicon dioxide (SiO2) | Synthetic silicon dioxide (SiO2) |

| Optical Properties | High clarity, birefringent | High transparency, isotropic |

| Mechanical Strength | Hard, brittle | Harder, more resistant to thermal shock |

| Thermal Properties | Stable up to 573degC (alpha-beta transition) | Stable up to ~1200degC, no phase transition |

| Applications | Oscillators, watches, electronic devices | Optical fiber, lenses, laboratory equipment |

| Production | Natural or synthetic crystal growth | Fused silica melting and cooling |

Quartz Crystal vs Quartz Glass: Key Differences

Quartz crystal is a naturally occurring mineral composed of silicon dioxide with a well-defined atomic structure, essential for piezoelectric applications, while quartz glass is a synthetic, non-crystalline form of silicon dioxide used primarily for its optical clarity and thermal resistance. Quartz crystal exhibits consistent vibrational frequencies making it ideal for precision oscillators in electronics, whereas quartz glass's amorphous nature provides superior transparency and thermal shock resistance in laboratory and industrial equipment. The fundamental difference lies in quartz crystal's ordered lattice enabling electronic precision, contrasting with quartz glass's disordered structure optimized for optical and thermal properties.

Composition and Structure Comparison

Quartz crystal consists of a naturally occurring, crystalline form of silicon dioxide (SiO2) with a well-ordered atomic lattice that imparts piezoelectric properties essential for electronic applications. Quartz glass, or fused silica, is an amorphous, non-crystalline form of silicon dioxide produced by melting high-purity quartz crystals and rapidly cooling to eliminate crystallinity, resulting in superior thermal and optical transparency. The distinct structural difference--crystalline versus amorphous silicon dioxide--dictates their respective mechanical strength, optical clarity, and electrical behaviors in industry and technology.

Manufacturing Processes: Natural vs Synthetic

Quartz crystal forms naturally through geological processes where silicon dioxide crystallizes over millions of years under high pressure and temperature, resulting in a hexagonal lattice structure with piezoelectric properties. Quartz glass, also known as fused quartz, is produced synthetically by melting high-purity quartz sand at extremely high temperatures followed by rapid cooling, creating an amorphous solid without crystalline structure. The natural formation of quartz crystal contrasts with the industrial manufacturing of quartz glass, emphasizing the differences in crystal morphology, purity, and applications in electronic and optical industries.

Physical Properties: Hardness and Durability

Quartz crystal exhibits a Mohs hardness of 7, making it notably resistant to scratching and physical wear compared to standard quartz glass, which is typically softer and more prone to surface damage. The crystalline structure of quartz crystal contributes to its superior durability and mechanical strength, maintaining integrity under high stress and temperature variations. In contrast, quartz glass, being an amorphous solid, lacks the ordered lattice, resulting in lower hardness and reduced resistance to thermal shock and mechanical abrasion.

Optical Clarity: Light Transmission and Purity

Quartz crystal exhibits exceptional optical clarity due to its natural crystalline structure, enabling superior light transmission and minimal distortion. In contrast, quartz glass, although transparent, often contains microscopic impurities and internal stresses that reduce purity and slightly diminish its light transmission efficiency. The intrinsic purity of quartz crystal enhances its performance in precision optical applications such as lasers and high-resolution lenses, where maximum clarity is critical.

Thermal Stability and Resistance

Quartz crystal exhibits superior thermal stability and resistance compared to quartz glass, maintaining structural integrity at temperatures exceeding 1,000degC without deforming or losing its piezoelectric properties. Quartz glass, while still heat resistant, softens at around 1,100degC and lacks the anisotropic thermal expansion characteristics found in quartz crystal, making it less stable under thermal stress. The low thermal expansion coefficient of quartz crystal ensures minimal dimensional changes during rapid temperature fluctuations, critical for precise resonators and sensors.

Industrial and Commercial Applications

Quartz crystal exhibits superior piezoelectric properties, making it essential for precise frequency control in oscillators and resonators used in telecommunications and industrial sensors. Quartz glass, highly resistant to thermal shock and chemical corrosion, is preferred for manufacturing high-performance lenses, laboratory equipment, and semiconductor processing components. The distinct physical and chemical properties of quartz crystal and quartz glass cater to specialized industrial and commercial requirements, optimizing functionality and durability.

Cost Analysis: Pricing and Value

Quartz crystal commands a higher price due to its natural formation and superior piezoelectric properties, making it ideal for high-precision applications like electronics and timekeeping. Quartz glass, synthesized through melting and rapid cooling, is more affordable and widely used in optics and laboratory equipment due to its thermal resistance and clarity. The cost difference reflects the balance between performance requirements and budget constraints in selecting either material.

Environmental Impact and Sustainability

Quartz crystal, a natural mineral, requires energy-intensive mining processes that disrupt ecosystems and contribute to habitat loss, whereas quartz glass is typically synthesized from abundant silicon dioxide with lower environmental degradation. Quartz glass production involves melting raw materials at high temperatures but allows for recycling and reuse, reducing waste compared to quartz crystal extraction. Sustainable practices in quartz glass manufacturing, such as energy-efficient furnaces and closed-loop recycling systems, significantly minimize carbon footprints and resource consumption.

Choosing the Right Quartz Material for Your Needs

Quartz Crystal offers superior piezoelectric properties essential for electronic oscillators and precise frequency control, making it ideal for high-accuracy applications. Quartz Glass, characterized by its exceptional thermal and chemical resistance, is preferred in optical instruments and laboratory equipment requiring transparency and durability. Selecting the right quartz material depends on whether electronic performance or structural resilience and clarity are prioritized in your project.

Quartz Crystal vs Quartz Glass Infographic

materialdif.com

materialdif.com