Low-grade quartz contains numerous impurities and structural flaws that reduce its clarity and durability, making it less suitable for precision applications. High-grade quartz exhibits high purity, exceptional clarity, and consistent crystal structure, essential for advanced technological uses such as semiconductors and optical instruments. The distinction between low-grade and high-grade quartz significantly impacts its value and usability across various industrial sectors.

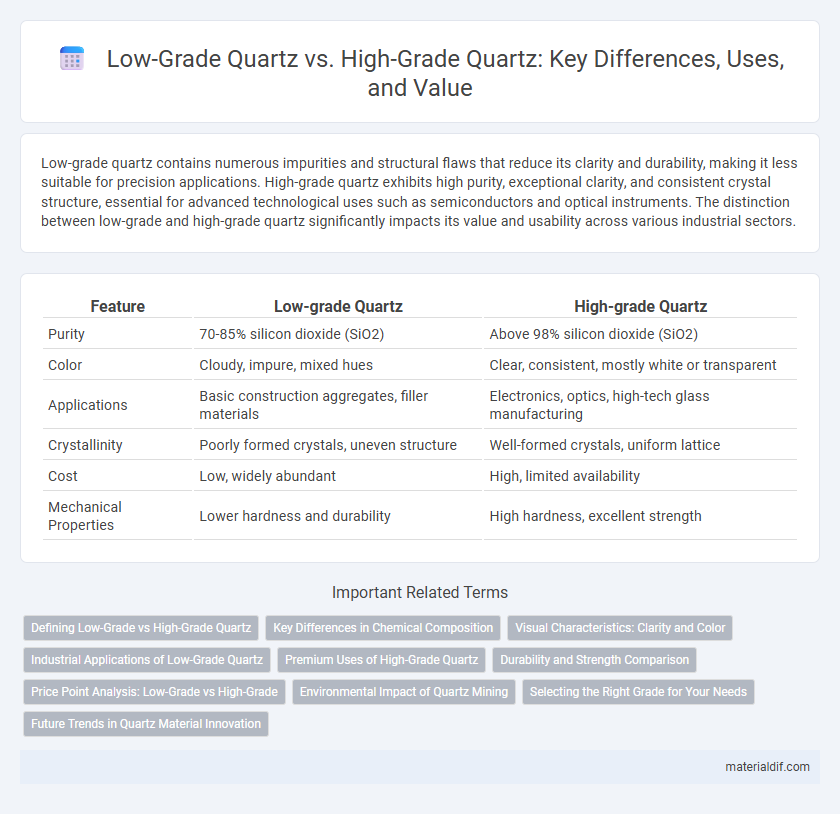

Table of Comparison

| Feature | Low-grade Quartz | High-grade Quartz |

|---|---|---|

| Purity | 70-85% silicon dioxide (SiO2) | Above 98% silicon dioxide (SiO2) |

| Color | Cloudy, impure, mixed hues | Clear, consistent, mostly white or transparent |

| Applications | Basic construction aggregates, filler materials | Electronics, optics, high-tech glass manufacturing |

| Crystallinity | Poorly formed crystals, uneven structure | Well-formed crystals, uniform lattice |

| Cost | Low, widely abundant | High, limited availability |

| Mechanical Properties | Lower hardness and durability | High hardness, excellent strength |

Defining Low-Grade vs High-Grade Quartz

Low-grade quartz contains a higher amount of impurities and lower crystallinity, which reduces its value and suitability for industrial applications such as electronics and optics. High-grade quartz exhibits exceptional purity with minimal inclusions, making it ideal for precise manufacturing processes requiring high thermal and chemical stability. The purity level, measured by the percentage of silicon dioxide (SiO2), is the key differentiator, with high-grade quartz typically exceeding 99.95% SiO2 content.

Key Differences in Chemical Composition

Low-grade quartz typically contains higher impurities such as iron, aluminum, and titanium oxides, which affect its purity and color, while high-grade quartz is characterized by a higher concentration of silicon dioxide (SiO2), often exceeding 99%. The chemical composition of high-grade quartz exhibits minimal trace elements, leading to superior clarity and enhanced performance in industrial applications like electronics and optics. Variations in impurity levels directly influence the physical properties and suitability of quartz for specialized uses, distinguishing low-grade from high-grade forms.

Visual Characteristics: Clarity and Color

Low-grade quartz typically exhibits cloudiness, inclusions, and a milky or dull appearance, lacking transparency and vibrant color. High-grade quartz boasts exceptional clarity, often being nearly transparent or colorless, with minimal impurities that allow light to pass through unobstructed. The color range of high-grade quartz can include vivid hues like amethyst purple or rose pink, whereas low-grade variants usually present muted or off-colors due to mineral contamination.

Industrial Applications of Low-Grade Quartz

Low-grade quartz, characterized by higher impurity levels and lower silicon dioxide content, is primarily utilized in industrial applications such as construction materials, glass manufacturing, and abrasive products where purity is less critical. Its cost-effectiveness and abundance make it suitable for producing concrete, ceramics, and filler materials in rubber and paint industries. Despite lower purity compared to high-grade quartz, low-grade quartz remains essential for bulk industrial processes requiring large volumes rather than ultra-high performance.

Premium Uses of High-Grade Quartz

High-grade quartz exhibits superior purity and clarity compared to low-grade quartz, making it essential for premium applications such as semiconductor manufacturing, optical instrumentation, and high-precision laboratory equipment. Its low impurity content and consistent crystalline structure ensure optimal performance and durability in advanced technology sectors. Industries rely on high-grade quartz to achieve enhanced electrical properties and thermal stability, which are critical for cutting-edge electronic devices and precision optics.

Durability and Strength Comparison

High-grade quartz features a denser crystalline structure, resulting in superior durability and greater resistance to scratches and impacts compared to low-grade quartz. Low-grade quartz tends to have more impurities and microfractures, which compromise its strength and make it more susceptible to chipping and wear over time. The enhanced hardness of high-grade quartz makes it ideal for demanding applications requiring long-lasting performance and minimal maintenance.

Price Point Analysis: Low-Grade vs High-Grade

Low-grade quartz typically commands a lower price point due to its higher impurity levels and limited applications in industrial and decorative uses. High-grade quartz, characterized by its exceptional purity and crystalline structure, attracts premium pricing driven by its demand in advanced electronics, optical devices, and luxury countertops. Price disparities between low-grade and high-grade quartz can reach 50-70%, reflecting the significant impact of purity and processing costs on market valuation.

Environmental Impact of Quartz Mining

Low-grade quartz mining generates a higher volume of waste rock and tailings, leading to increased soil erosion and habitat disruption compared to high-grade quartz extraction. High-grade quartz mining, though less wasteful, often involves energy-intensive processes that raise greenhouse gas emissions and water consumption. Implementing sustainable mining techniques and proper waste management can mitigate the environmental impact from both low-grade and high-grade quartz operations.

Selecting the Right Grade for Your Needs

Low-grade quartz contains higher impurities, making it suitable for construction applications where durability is necessary but aesthetic perfection is less critical. High-grade quartz offers superior purity and enhanced physical properties, ideal for precision instruments, electronics, and luxury countertops. Selecting the right grade depends on the intended use, balancing cost considerations against performance and appearance requirements.

Future Trends in Quartz Material Innovation

Low-grade quartz often contains impurities and lower silica content, limiting its applications, while high-grade quartz boasts superior purity and crystalline quality, making it ideal for advanced electronics and optical industries. Future trends in quartz material innovation emphasize enhancing material purity through cutting-edge refining techniques and developing synthetic quartz with tailored properties to meet increasing demands in semiconductor manufacturing and renewable energy technologies. Emerging research explores nanostructured quartz composites to improve durability and functional performance, driving breakthroughs in high-precision instruments and photonic devices.

Low-grade Quartz vs High-grade Quartz Infographic

materialdif.com

materialdif.com