Quartz is a natural mineral commonly used in countertops, while engineered quartz is a man-made product combining crushed quartz with resins and pigments for enhanced durability. Engineered quartz offers greater design versatility, consistent patterns, and resistance to stains and scratches compared to natural quartz. Both materials provide excellent hardness and low porosity, but engineered quartz requires less maintenance and customizes better to modern interior styles.

Table of Comparison

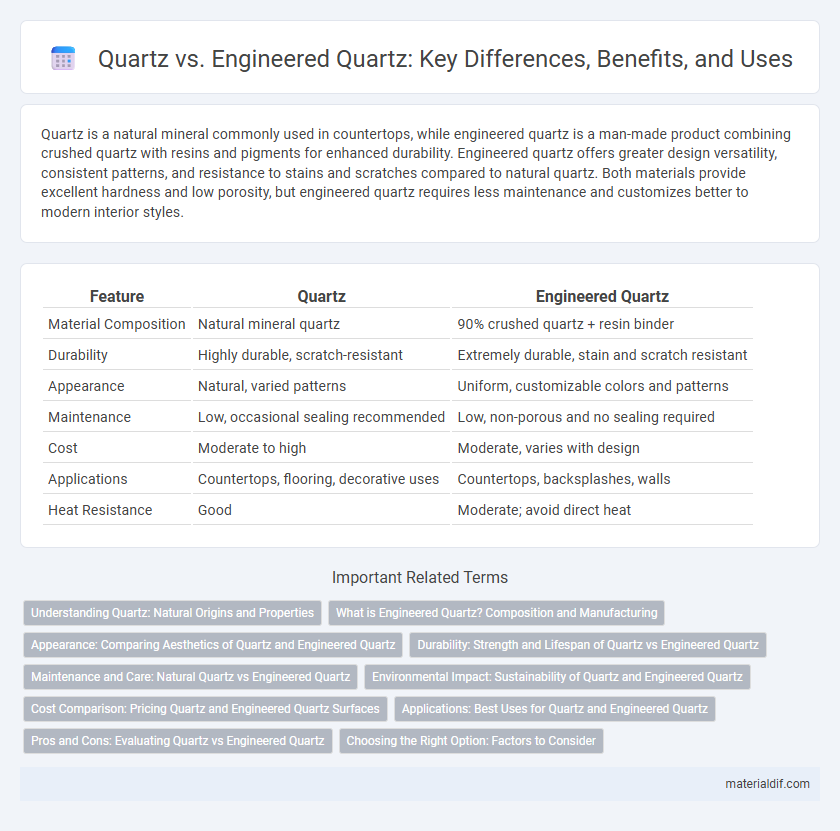

| Feature | Quartz | Engineered Quartz |

|---|---|---|

| Material Composition | Natural mineral quartz | 90% crushed quartz + resin binder |

| Durability | Highly durable, scratch-resistant | Extremely durable, stain and scratch resistant |

| Appearance | Natural, varied patterns | Uniform, customizable colors and patterns |

| Maintenance | Low, occasional sealing recommended | Low, non-porous and no sealing required |

| Cost | Moderate to high | Moderate, varies with design |

| Applications | Countertops, flooring, decorative uses | Countertops, backsplashes, walls |

| Heat Resistance | Good | Moderate; avoid direct heat |

Understanding Quartz: Natural Origins and Properties

Quartz is a natural mineral composed primarily of silicon dioxide, renowned for its durability, hardness, and resistance to heat and scratches. Formed through geological processes over millions of years, natural quartz exhibits unique variations in color and veining that are highly valued in countertops and decorative applications. Its inherent strength and non-porous nature make it a preferred material for both natural specimens and engineered quartz products.

What is Engineered Quartz? Composition and Manufacturing

Engineered quartz is a man-made composite material composed of approximately 90-95% natural quartz crystals combined with resin polymers and pigments, enhancing durability and design versatility. Manufactured through a process that blends crushed quartz with binding agents before being compressed and cured under high heat and pressure, engineered quartz offers consistent quality and a wide range of colors and patterns. This composition results in a non-porous, stain-resistant surface ideal for countertops, distinguishing it from natural quartz, which is a pure mineral formed naturally within the earth.

Appearance: Comparing Aesthetics of Quartz and Engineered Quartz

Natural quartz showcases unique, intricate patterns and color variations formed by geological processes, creating a distinctive and organic aesthetic. Engineered quartz offers consistent color and pattern uniformity due to its manufactured composition, enabling precise matching and a polished, modern look. The choice between natural quartz and engineered quartz often depends on preference for natural variation versus predictable, customizable design.

Durability: Strength and Lifespan of Quartz vs Engineered Quartz

Natural quartz boasts excellent hardness with a Mohs rating of 7, contributing to its impressive scratch resistance and durability over time. Engineered quartz combines crushed quartz with resins and polymers, enhancing its strength and making it non-porous, which significantly improves stain resistance and lifespan compared to natural quartz. Both materials are highly durable, but engineered quartz offers superior longevity and low maintenance due to its consistent composition and added protective elements.

Maintenance and Care: Natural Quartz vs Engineered Quartz

Natural quartz countertops require sealing to prevent staining and should be cleaned with pH-neutral cleaners to maintain their surface integrity. Engineered quartz offers enhanced stain resistance and does not need sealing, making it easier to maintain with simple soap and water solutions. Both materials benefit from avoiding abrasive cleaners and heat exposure to prolong their durability and appearance.

Environmental Impact: Sustainability of Quartz and Engineered Quartz

Natural quartz extraction involves significant energy consumption and habitat disruption, raising environmental concerns. Engineered quartz, composed of approximately 90% quartz combined with resins and pigments, offers greater sustainability by utilizing industrial byproducts and reducing quarrying impact. The manufacturing process of engineered quartz promotes resource efficiency and lowers waste, making it a more eco-friendly alternative in surface material selection.

Cost Comparison: Pricing Quartz and Engineered Quartz Surfaces

Quartz surfaces generally cost between $50 and $100 per square foot, while engineered quartz ranges from $60 to $120 per square foot due to added manufacturing processes and design options. Natural quartz requires less processing, leading to lower material expenses, whereas engineered quartz incorporates resins and pigments that increase production costs. Homeowners should factor in installation fees and surface durability when comparing the overall value of quartz versus engineered quartz countertops.

Applications: Best Uses for Quartz and Engineered Quartz

Quartz excels in applications requiring natural aesthetic and durability, such as kitchen countertops, bathroom vanities, and wall cladding, benefiting from its natural mineral composition. Engineered quartz suits high-traffic areas like commercial spaces, including office countertops, restaurant surfaces, and laboratory benches, due to its enhanced resistance to stains, scratches, and bacteria. Both materials offer versatility in interior design but differ in maintenance and performance based on their composition and intended use.

Pros and Cons: Evaluating Quartz vs Engineered Quartz

Quartz offers natural beauty and unique veining patterns, making it highly desirable for decorative purposes, but it can be more porous and prone to staining compared to engineered quartz. Engineered quartz provides superior durability, non-porous surface, and consistent design options due to its composite of quartz particles and resin, yet it may lack the authentic look of natural quartz. Choosing between quartz and engineered quartz depends on priorities like maintenance ease, aesthetic preference, and budget.

Choosing the Right Option: Factors to Consider

Quartz offers natural variations and unique patterns due to its mined origin, making it ideal for those seeking authentic stone aesthetics. Engineered quartz provides consistent color, enhanced durability, and low porosity, suitable for high-traffic areas requiring easy maintenance. Cost, design preference, and application environment are critical factors when choosing between natural quartz and engineered quartz surfaces.

Quartz vs Engineered Quartz Infographic

materialdif.com

materialdif.com