Quartz rods offer high purity and excellent thermal stability, making them ideal for precision applications like semiconductor manufacturing and optical instruments. Quartz tubes provide larger surface areas and are preferred for heating elements in industrial furnaces and chemical processing due to their durability and resistance to thermal shock. Both forms leverage quartz's unique properties but serve distinct roles based on shape, size, and specific performance requirements.

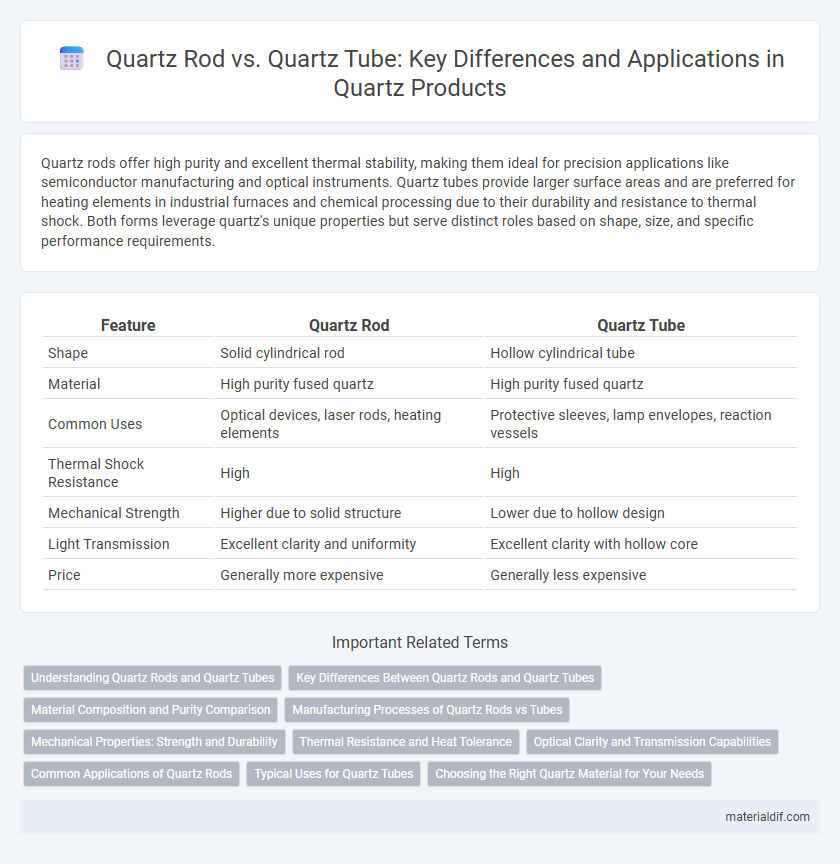

Table of Comparison

| Feature | Quartz Rod | Quartz Tube |

|---|---|---|

| Shape | Solid cylindrical rod | Hollow cylindrical tube |

| Material | High purity fused quartz | High purity fused quartz |

| Common Uses | Optical devices, laser rods, heating elements | Protective sleeves, lamp envelopes, reaction vessels |

| Thermal Shock Resistance | High | High |

| Mechanical Strength | Higher due to solid structure | Lower due to hollow design |

| Light Transmission | Excellent clarity and uniformity | Excellent clarity with hollow core |

| Price | Generally more expensive | Generally less expensive |

Understanding Quartz Rods and Quartz Tubes

Quartz rods and quartz tubes are both high-purity silica materials used in industrial and scientific applications, but they differ in shape and functionality. Quartz rods are solid cylindrical pieces offering excellent thermal stability and mechanical strength, ideal for optical components and heating elements, while quartz tubes are hollow cylinders commonly used for chemical reactions, laboratory equipment, and protective enclosures with superior thermal shock resistance. Understanding the differences between quartz rods and tubes ensures the selection of the appropriate material for specific needs in optics, electronics, and chemical processing industries.

Key Differences Between Quartz Rods and Quartz Tubes

Quartz rods and quartz tubes differ primarily in shape and application, with rods being solid cylindrical pieces while tubes are hollow and shaped like cylinders with a hollow center. Quartz rods offer superior rigidity and are frequently used in precision instruments, whereas quartz tubes provide enhanced thermal insulation and fluid containment for applications like heating elements and laboratory equipment. The material purity and thermal resistance remain high in both, but the choice depends on whether structural strength or fluid flow is the priority.

Material Composition and Purity Comparison

Quartz rods and quartz tubes differ primarily in shape but share similar material composition, both made from high-purity silicon dioxide (SiO2). Quartz rods generally exhibit higher uniformity in purity due to the controlled manufacturing process, resulting in fewer impurities and inclusions compared to quartz tubes. The enhanced purity of quartz rods makes them preferable in applications demanding superior optical clarity and thermal stability.

Manufacturing Processes of Quartz Rods vs Tubes

Quartz rods are typically manufactured through a precision drawing process where molten quartz is carefully pulled to form solid cylindrical shapes, ensuring high purity and uniformity suited for optical and electronic applications. In contrast, quartz tubes are produced using a combination of blowing and rotational shaping techniques, where molten quartz is inflated and rotated to create hollow cylindrical structures with consistent wall thickness, ideal for laboratory and industrial uses. The distinct manufacturing processes directly impact the mechanical properties and application suitability of quartz rods and tubes.

Mechanical Properties: Strength and Durability

Quartz rods exhibit higher mechanical strength and durability due to their solid, uniform structure, making them ideal for applications requiring resistance to impact and bending. Quartz tubes, while offering superior thermal shock resistance and flexibility, generally possess lower tensile strength compared to rods, which can limit their performance under heavy mechanical stress. The choice between quartz rod and tube depends on balancing the need for mechanical robustness with thermal and chemical stability in specific industrial environments.

Thermal Resistance and Heat Tolerance

Quartz rods exhibit higher thermal resistance and superior heat tolerance compared to quartz tubes, making them ideal for applications requiring sustained exposure to extreme temperatures. The solid structure of quartz rods allows for better heat distribution and minimizes thermal shock risks, whereas quartz tubes, being hollow, may have lower thermal thresholds and are more prone to cracking under rapid temperature changes. Selecting between quartz rod and tube depends on the specific heat endurance and durability needs of high-temperature industrial processes.

Optical Clarity and Transmission Capabilities

Quartz rods offer superior optical clarity compared to quartz tubes due to their solid, homogeneous structure, minimizing light scattering and absorption. The transmission capabilities of quartz rods are optimized for precise applications requiring high purity and low signal loss, especially in ultraviolet to infrared wavelengths. Quartz tubes, while still effective, often exhibit slightly lower transmission efficiency because of their hollow, cylindrical design which can introduce internal reflections and minor optical distortions.

Common Applications of Quartz Rods

Quartz rods are widely used in industrial heating elements, laboratory equipment, and optical devices due to their excellent thermal stability and chemical resistance. Their applications include infrared heating systems, UV lamp sleeves, and precision alignment tools in semiconductor manufacturing. Compared to quartz tubes, quartz rods provide greater structural integrity and uniform heat distribution, making them ideal for high-temperature and precision-demanding processes.

Typical Uses for Quartz Tubes

Quartz tubes are commonly used in laboratory and industrial applications for their excellent resistance to high temperatures and chemical corrosion, making them ideal for heating elements, protective covers, and light transmission in UV lamps. Their tubular shape allows for efficient gas flow and containment in processes such as semiconductor manufacturing and chemical vapor deposition. Quartz tubes also serve as durable containers in furnaces and reactors where stable thermal insulation and transparency to specific wavelengths are required.

Choosing the Right Quartz Material for Your Needs

Quartz rods offer superior strength and thermal stability, making them ideal for high-temperature applications such as laboratory equipment and UV lamps. Quartz tubes provide excellent chemical resistance and are commonly used in protective casing and fluid transport systems. Selecting between quartz rod and tube depends on the specific requirements for mechanical durability, thermal performance, and shape configuration in your project.

Quartz Rod vs Quartz Tube Infographic

materialdif.com

materialdif.com