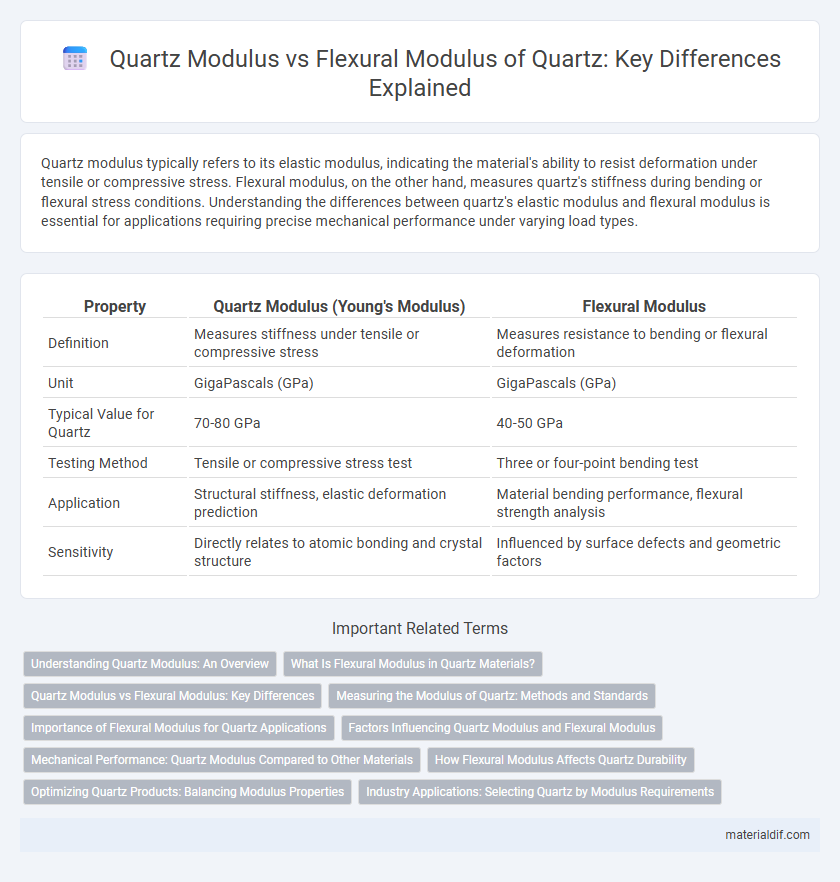

Quartz modulus typically refers to its elastic modulus, indicating the material's ability to resist deformation under tensile or compressive stress. Flexural modulus, on the other hand, measures quartz's stiffness during bending or flexural stress conditions. Understanding the differences between quartz's elastic modulus and flexural modulus is essential for applications requiring precise mechanical performance under varying load types.

Table of Comparison

| Property | Quartz Modulus (Young's Modulus) | Flexural Modulus |

|---|---|---|

| Definition | Measures stiffness under tensile or compressive stress | Measures resistance to bending or flexural deformation |

| Unit | GigaPascals (GPa) | GigaPascals (GPa) |

| Typical Value for Quartz | 70-80 GPa | 40-50 GPa |

| Testing Method | Tensile or compressive stress test | Three or four-point bending test |

| Application | Structural stiffness, elastic deformation prediction | Material bending performance, flexural strength analysis |

| Sensitivity | Directly relates to atomic bonding and crystal structure | Influenced by surface defects and geometric factors |

Understanding Quartz Modulus: An Overview

Quartz modulus primarily refers to the Young's modulus of quartz, measuring its stiffness or resistance to elastic deformation under tensile or compressive stress, typically around 70 GPa. Flexural modulus, on the other hand, quantifies the material's ability to resist deformation under bending stress, providing insights into quartz's performance in applications involving flexure. Understanding these moduli helps engineers select quartz for precise optical components, resonators, and microelectromechanical systems where mechanical stability and flexibility are critical.

What Is Flexural Modulus in Quartz Materials?

Flexural modulus in quartz materials measures the material's resistance to bending under stress, reflecting its stiffness in flexure tests. Unlike quartz modulus, which generally refers to bulk elasticity, flexural modulus specifically quantifies how quartz responds to bending forces, making it critical for applications involving structural support or mechanical load. High flexural modulus values in quartz indicate strong rigidity and minimal deformation when subjected to bending stresses.

Quartz Modulus vs Flexural Modulus: Key Differences

Quartz modulus, primarily representing its elastic modulus or Young's modulus, measures the material's resistance to elastic deformation under tensile or compressive stress. Flexural modulus, on the other hand, quantifies quartz's stiffness during bending or flexural stress, reflecting its ability to resist deformation when subjected to load across a beam or plate. Key differences lie in the type of stress measured: quartz modulus applies to linear, axial forces, while flexural modulus assesses resistance to bending, making the latter critical for applications involving structural flexing or load-bearing surfaces.

Measuring the Modulus of Quartz: Methods and Standards

Measuring the modulus of quartz involves assessing both the quartz modulus and flexural modulus to understand material stiffness under different stress conditions. Standard methods like ASTM E1876 for dynamic modulus measurement and ASTM D790 for flexural testing provide reliable protocols for evaluating quartz's mechanical properties. Accurate characterization requires precise instrumentation such as nanoindentation or resonant frequency techniques, ensuring adherence to these industry standards for consistency and reproducibility.

Importance of Flexural Modulus for Quartz Applications

Flexural modulus is a critical property for quartz in applications requiring high mechanical strength and resistance to bending under stress, such as in precision optical components and electronic substrates. Quartz exhibits a higher flexural modulus compared to its quartz modulus, making it more reliable for structural integrity under flexural loads. Understanding the flexural modulus ensures optimal material selection for durability and performance in demanding industrial uses.

Factors Influencing Quartz Modulus and Flexural Modulus

Quartz modulus, including Young's modulus and flexural modulus, is influenced by crystal structure, purity, and temperature, which affect its stiffness and deformation response. Impurities and defects disrupt atomic bonding, reducing modulus values, while temperature variations cause lattice expansion or contraction, altering elastic properties. Mechanical loading conditions and grain orientation further impact flexural modulus by modifying stress distribution and flexural strength in quartz materials.

Mechanical Performance: Quartz Modulus Compared to Other Materials

Quartz exhibits a high elastic modulus typically around 70 GPa, indicating significant stiffness compared to many common materials like polymers and some metals. Its flexural modulus, which measures resistance to bending, closely aligns with the Young's modulus due to quartz's crystalline structure and uniform mechanical properties. This superior mechanical performance makes quartz ideal for applications requiring rigidity and deformation resistance, outperforming materials such as glass and certain ceramics in structural stability.

How Flexural Modulus Affects Quartz Durability

The flexural modulus measures quartz's resistance to bending under load, directly influencing its durability in structural applications. Higher flexural modulus values indicate greater stiffness, minimizing deformation and enhancing quartz's ability to withstand mechanical stress and impact. This property is critical for quartz used in countertops, flooring, and engineered stone, where prolonged mechanical endurance and resistance to cracking are essential.

Optimizing Quartz Products: Balancing Modulus Properties

Quartz products require a precise balance between Quartz Modulus and Flexural Modulus to optimize performance in various industrial applications. Quartz Modulus, reflecting the material's stiffness under compressive stress, must be matched with Flexural Modulus, which measures resistance to bending forces, to ensure durability and structural integrity. Tailoring these modulus properties enhances the reliability of quartz in electronics, optics, and precision instruments.

Industry Applications: Selecting Quartz by Modulus Requirements

Quartz exhibits distinct mechanical properties, where the Modulus of Elasticity (Quartz Modulus) measures its stiffness under tensile or compressive stress, while the Flexural Modulus assesses resistance to bending forces. Industry applications such as electronics, optics, and precision instruments select quartz based on these modulus values to ensure material performance under specific loading conditions. Optimizing quartz selection by modulus requirements enhances durability, reliability, and functionality in high-precision manufacturing and structural applications.

Quartz Modulus vs Flexural Modulus Infographic

materialdif.com

materialdif.com