Fused quartz is a non-crystalline, amorphous form of silicon dioxide produced by melting high-purity silica, resulting in a material with exceptional thermal stability and low thermal expansion. Crystalline quartz, by contrast, features an ordered atomic structure with piezoelectric properties, making it ideal for electronic applications like oscillators and sensors. The distinct microstructures of fused and crystalline quartz influence their optical clarity, mechanical strength, and suitability across various industrial uses.

Table of Comparison

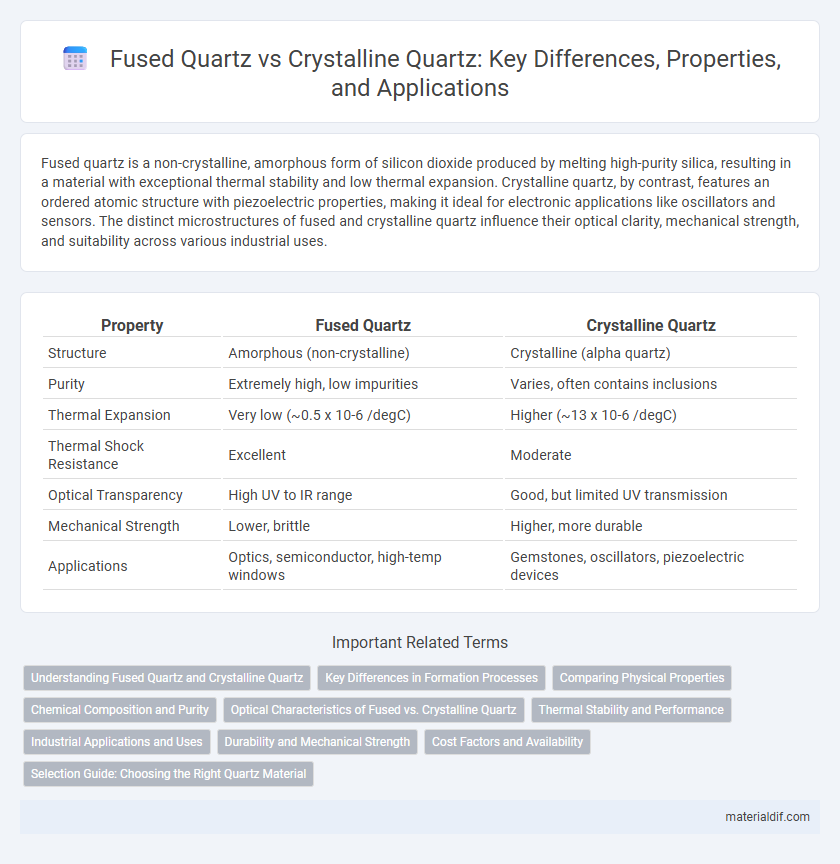

| Property | Fused Quartz | Crystalline Quartz |

|---|---|---|

| Structure | Amorphous (non-crystalline) | Crystalline (alpha quartz) |

| Purity | Extremely high, low impurities | Varies, often contains inclusions |

| Thermal Expansion | Very low (~0.5 x 10-6 /degC) | Higher (~13 x 10-6 /degC) |

| Thermal Shock Resistance | Excellent | Moderate |

| Optical Transparency | High UV to IR range | Good, but limited UV transmission |

| Mechanical Strength | Lower, brittle | Higher, more durable |

| Applications | Optics, semiconductor, high-temp windows | Gemstones, oscillators, piezoelectric devices |

Understanding Fused Quartz and Crystalline Quartz

Fused quartz is a non-crystalline, amorphous form of silicon dioxide created by melting high-purity quartz crystals, offering superior thermal stability and optical clarity. Crystalline quartz consists of a structured lattice of silicon dioxide, known for its piezoelectric properties and commonly used in electronic oscillators and precision instruments. Understanding the differences between fused quartz and crystalline quartz is crucial for applications requiring specific thermal, optical, or electrical characteristics.

Key Differences in Formation Processes

Fused quartz forms through the melting and rapid cooling of high-purity silica, resulting in an amorphous, non-crystalline structure with superior thermal stability and optical clarity. Crystalline quartz develops naturally over long geological periods via the slow cooling and crystallization of silicon dioxide, forming a well-ordered crystal lattice that influences its physical properties. These distinct formation processes determine the differences in durability, transparency, and applications of fused quartz versus crystalline quartz in industries such as optics and electronics.

Comparing Physical Properties

Fused quartz exhibits higher thermal shock resistance and lower thermal expansion coefficient (approximately 0.5 x 10^-6 /degC) compared to crystalline quartz, which has a thermal expansion coefficient around 13 x 10^-6 /degC. Fused quartz is amorphous, resulting in superior optical transparency and resistance to UV radiation, while crystalline quartz's piezoelectric properties make it valuable for electronic applications. Mechanical strength of fused quartz is typically greater due to the absence of grain boundaries that are present in crystalline quartz, influencing fracture toughness and durability.

Chemical Composition and Purity

Fused quartz consists of high-purity silicon dioxide (SiO2) produced by melting natural quartz or synthetic silica, resulting in an almost entirely amorphous structure with minimal impurities. Crystalline quartz is composed of naturally occurring silicon dioxide arranged in a well-defined crystal lattice, often containing trace impurities such as aluminum, iron, or lithium. The chemical purity of fused quartz is significantly higher than crystalline quartz, making it ideal for applications requiring exceptional optical transparency and thermal stability.

Optical Characteristics of Fused vs. Crystalline Quartz

Fused quartz exhibits superior optical clarity and lower birefringence compared to crystalline quartz, making it ideal for high-precision optical applications. It has a broader transmission range in the ultraviolet to infrared spectrum, with minimal light scattering due to its non-crystalline structure. Crystalline quartz, while useful for its piezoelectric properties, shows higher birefringence and less uniform optical characteristics, limiting its use in advanced optical systems.

Thermal Stability and Performance

Fused quartz exhibits superior thermal stability compared to crystalline quartz due to its non-crystalline, amorphous structure, which minimizes thermal expansion and enhances resistance to thermal shock. Crystalline quartz tends to undergo phase transformations at elevated temperatures, leading to dimensional changes and potential structural stress during heating and cooling cycles. This makes fused quartz the preferred material for high-temperature applications requiring consistent performance and durability under thermal stress.

Industrial Applications and Uses

Fused quartz, known for its high purity and thermal stability, is widely used in semiconductor manufacturing, fiber optics, and high-temperature industrial processes due to its excellent resistance to thermal shock and chemical inertness. Crystalline quartz, with its piezoelectric properties, plays a critical role in electronic oscillators, sensors, and precision timing devices, making it indispensable in telecommunications and instrumentation industries. Industrial applications leverage fused quartz for its optical clarity and mechanical strength in demanding environments, while crystalline quartz is favored for electronic and frequency control components.

Durability and Mechanical Strength

Fused quartz exhibits superior durability and mechanical strength compared to crystalline quartz, due to its non-crystalline amorphous structure that resists thermal shock and mechanical stress more effectively. The absence of grain boundaries in fused quartz results in higher fracture toughness and greater resistance to cracking under pressure. Crystalline quartz, with its ordered atomic lattice, tends to be more brittle and susceptible to microfractures, limiting its performance in high-stress applications.

Cost Factors and Availability

Fused quartz, made by melting high-purity silica sand, generally costs more than crystalline quartz due to its superior purity and thermal stability, though it offers consistent availability from specialized suppliers. Crystalline quartz, sourced naturally and requiring minimal processing, is often less expensive and more widely available but may contain impurities affecting its performance in precision applications. Cost factors for fused quartz include energy-intensive production and raw material quality, while crystalline quartz costs hinge on mining and processing expenses.

Selection Guide: Choosing the Right Quartz Material

Fused quartz, composed of pure silicon dioxide with a non-crystalline amorphous structure, offers superior thermal stability, low thermal expansion, and excellent optical clarity, making it ideal for high-temperature and precision optical applications. Crystalline quartz, characterized by its ordered atomic structure and piezoelectric properties, excels in electronic components and frequency control devices. Selecting the right quartz material depends on application-specific requirements such as thermal resistance, optical transparency, mechanical strength, and electrical properties.

Fused Quartz vs Crystalline Quartz Infographic

materialdif.com

materialdif.com