Fused quartz is a high-purity, non-crystalline form of silicon dioxide created by melting natural quartz crystals, offering superior thermal stability and resistance to chemical corrosion compared to quartz glass. Quartz glass, often produced by melting quartz sand or other silica sources, can contain impurities that affect its optical and mechanical properties. The choice between fused quartz and quartz glass depends on the application's demand for purity, thermal performance, and durability.

Table of Comparison

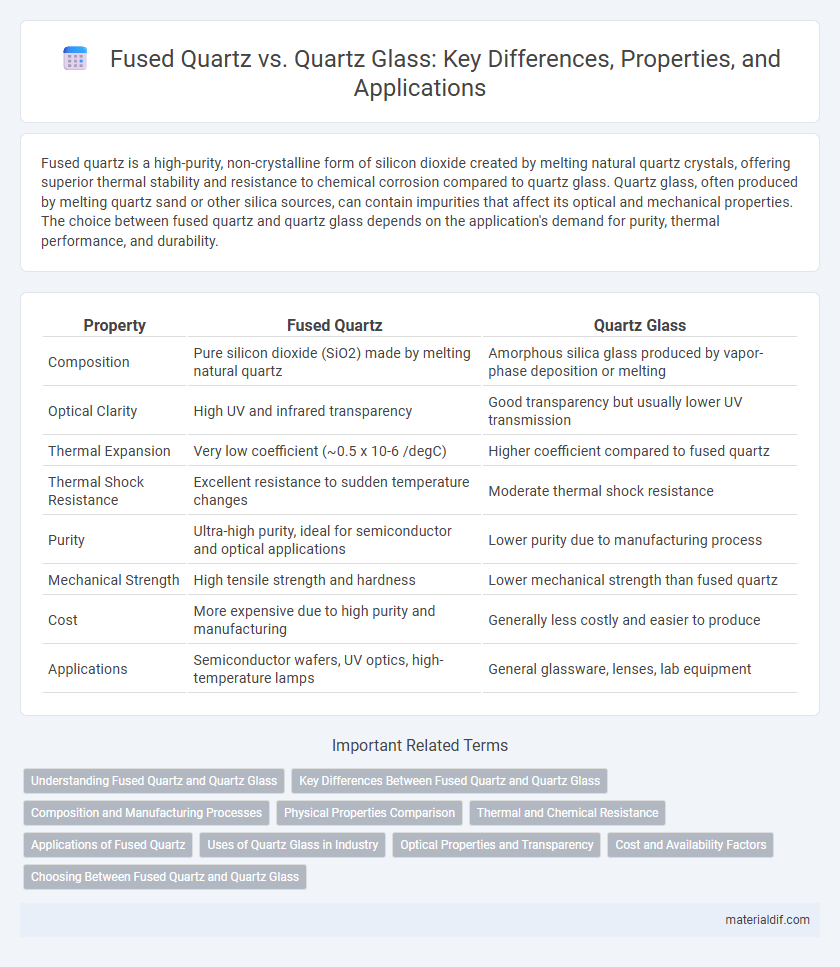

| Property | Fused Quartz | Quartz Glass |

|---|---|---|

| Composition | Pure silicon dioxide (SiO2) made by melting natural quartz | Amorphous silica glass produced by vapor-phase deposition or melting |

| Optical Clarity | High UV and infrared transparency | Good transparency but usually lower UV transmission |

| Thermal Expansion | Very low coefficient (~0.5 x 10-6 /degC) | Higher coefficient compared to fused quartz |

| Thermal Shock Resistance | Excellent resistance to sudden temperature changes | Moderate thermal shock resistance |

| Purity | Ultra-high purity, ideal for semiconductor and optical applications | Lower purity due to manufacturing process |

| Mechanical Strength | High tensile strength and hardness | Lower mechanical strength than fused quartz |

| Cost | More expensive due to high purity and manufacturing | Generally less costly and easier to produce |

| Applications | Semiconductor wafers, UV optics, high-temperature lamps | General glassware, lenses, lab equipment |

Understanding Fused Quartz and Quartz Glass

Fused quartz is a high-purity, non-crystalline form of silicon dioxide created by melting natural quartz crystals at extreme temperatures, resulting in exceptional thermal stability and optical clarity. Quartz glass, often used interchangeably with fused quartz, is a synthetic, transparent material produced through melting high-purity silica powder, offering consistent chemical resistance and superior UV transmission. Both materials serve critical roles in industries requiring durable, heat-resistant, and optically clear components, such as semiconductor manufacturing and scientific instrumentation.

Key Differences Between Fused Quartz and Quartz Glass

Fused quartz is a high-purity silica glass made by melting natural quartz crystals at extremely high temperatures, resulting in exceptional thermal stability and resistance to thermal shock, whereas quartz glass is typically manufactured from various silica sources, including synthetic materials and may contain impurities. Fused quartz offers superior optical transparency in ultraviolet and infrared spectrums, making it ideal for high-precision optical components, while quartz glass often has slightly lower optical clarity and thermal resistance. The key differences lie in their manufacturing processes, purity levels, and performance characteristics, with fused quartz providing enhanced durability and purity for advanced industrial and scientific applications.

Composition and Manufacturing Processes

Fused quartz is made from high-purity silica (SiO2) melted at extremely high temperatures, resulting in a non-crystalline, amorphous solid with superior thermal and chemical resistance. Quartz glass, often produced through the fusion of natural quartz crystals, contains microscopic crystallites that can affect optical clarity and structural uniformity. The manufacturing process of fused quartz involves melting synthetic silica in a controlled environment, whereas quartz glass typically involves melting and refining natural quartz, influencing the final material's purity and performance.

Physical Properties Comparison

Fused quartz and quartz glass both originate from high-purity silica but differ significantly in physical properties; fused quartz is made by melting natural quartz crystals, resulting in higher thermal stability and resistance to thermal shock with a melting point around 1713degC. Quartz glass, often fabricated through flame fusion or chemical vapor deposition, presents slightly lower thermal conductivity and mechanical strength but offers superior optical clarity and uniformity. The thermal expansion coefficient of fused quartz is approximately 0.55 x 10-6 /degC, making it ideal for high-temperature applications, while quartz glass typically exhibits higher expansion rates, limiting its use in extreme environments.

Thermal and Chemical Resistance

Fused quartz exhibits superior thermal resistance, withstanding temperatures up to 1,200degC without deformation, compared to quartz glass, which typically withstands up to 600degC. Chemically, fused quartz resists most acids and alkalis except hydrofluoric acid, making it ideal for harsh chemical environments, whereas quartz glass shows lower chemical durability. This enhanced thermal and chemical stability positions fused quartz as the preferred material for high-performance industrial applications.

Applications of Fused Quartz

Fused quartz is widely used in high-precision optical applications such as ultraviolet lamps, semiconductor manufacturing, and fiber optics due to its exceptional thermal stability and high purity. Unlike quartz glass, fused quartz offers superior resistance to thermal shock and chemical corrosion, making it ideal for laboratory crucibles and aerospace components. Its excellent transparency across a broad spectrum--from ultraviolet to infrared--enables critical performance in laser systems and photolithography processes.

Uses of Quartz Glass in Industry

Quartz glass, also known as fused silica, is widely used in industries requiring high thermal stability and chemical resistance, such as semiconductor manufacturing and aerospace engineering. Its exceptional transparency to ultraviolet light makes it ideal for optical components, including lenses and fiber optics. Quartz glass is crucial in laboratory equipment and high-intensity lighting due to its purity and durability under extreme conditions.

Optical Properties and Transparency

Fused quartz exhibits superior optical clarity with a broad transmission range from ultraviolet (UV) to near-infrared (NIR) wavelengths, maintaining low optical absorption and minimal birefringence. Quartz glass, although similar, typically has slightly lower purity, resulting in reduced UV transparency and higher absorption in the short-wavelength spectrum. Both materials offer excellent thermal stability, but fused quartz is preferred in high-precision optics due to its higher homogeneity and lower defect density that enhance overall transparency.

Cost and Availability Factors

Fused quartz costs significantly more than quartz glass due to its superior purity and manufacturing process that requires melting high-purity silica at extremely high temperatures. Quartz glass, often made from lower-purity silica or synthesized materials, is more readily available and affordable for general industrial applications. Cost and availability factors make fused quartz ideal for specialized optical and semiconductor uses, while quartz glass suits budget-conscious projects requiring decent thermal and chemical resistance.

Choosing Between Fused Quartz and Quartz Glass

Fused quartz and quartz glass both offer high purity and excellent thermal stability, making them ideal for precision optical applications. Fused quartz is fabricated through melting natural quartz crystals, resulting in superior chemical durability and UV transmission, while quartz glass is typically made from synthetic silica, providing consistent quality and lower birefringence. Selecting between fused quartz and quartz glass depends on specific requirements such as thermal shock resistance, optical clarity, and cost considerations for industrial or scientific use.

Fused Quartz vs Quartz Glass Infographic

materialdif.com

materialdif.com