Monocrystalline quartz features a uniform crystal structure that provides higher purity and superior durability, making it ideal for precision applications and high-end jewelry. Polycrystalline quartz consists of multiple crystals fused together, resulting in lower purity but increased mechanical strength and affordability for industrial uses. Both types offer unique advantages depending on the required balance between performance and cost.

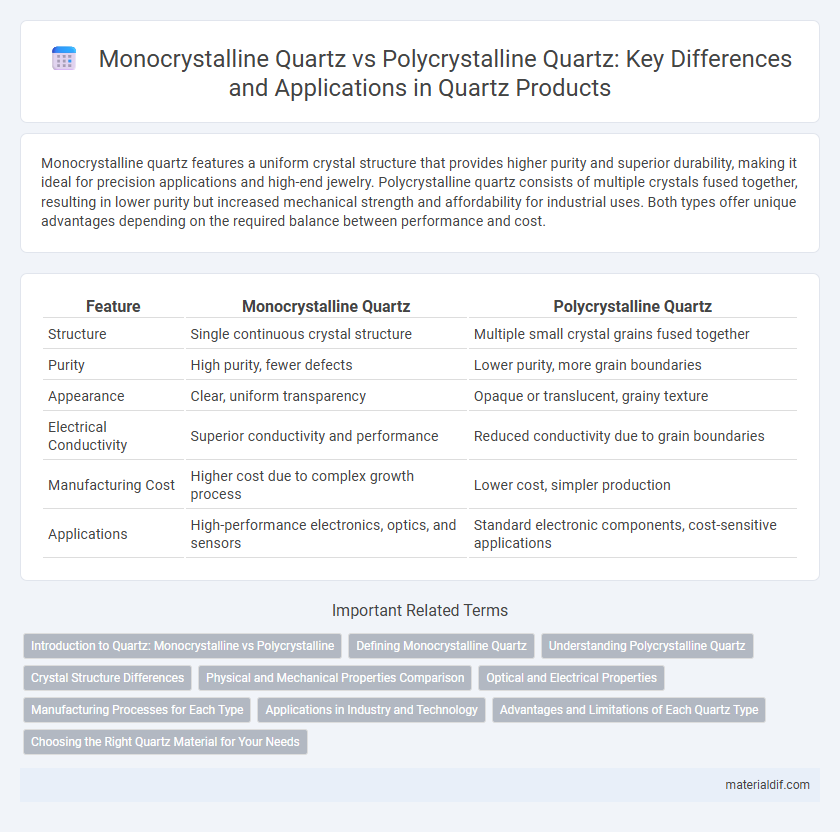

Table of Comparison

| Feature | Monocrystalline Quartz | Polycrystalline Quartz |

|---|---|---|

| Structure | Single continuous crystal structure | Multiple small crystal grains fused together |

| Purity | High purity, fewer defects | Lower purity, more grain boundaries |

| Appearance | Clear, uniform transparency | Opaque or translucent, grainy texture |

| Electrical Conductivity | Superior conductivity and performance | Reduced conductivity due to grain boundaries |

| Manufacturing Cost | Higher cost due to complex growth process | Lower cost, simpler production |

| Applications | High-performance electronics, optics, and sensors | Standard electronic components, cost-sensitive applications |

Introduction to Quartz: Monocrystalline vs Polycrystalline

Monocrystalline quartz features a uniform crystal structure formed from a single continuous crystal, resulting in higher purity and enhanced piezoelectric properties essential for precision electronic applications. Polycrystalline quartz consists of multiple small quartz crystals fused together, exhibiting more grain boundaries that can affect electrical performance but offer cost-effective production for less demanding uses. Understanding the structural differences informs the selection between monocrystalline quartz for high-performance oscillators and polycrystalline quartz for general frequency control devices.

Defining Monocrystalline Quartz

Monocrystalline quartz consists of a single, continuous crystal lattice, giving it superior purity, uniformity, and stability compared to polycrystalline quartz. This structure is essential for high-performance electronic and optical applications, as it reduces defects and enhances signal precision. Monocrystalline quartz's consistent molecular alignment contributes to its durability and high-frequency oscillation accuracy.

Understanding Polycrystalline Quartz

Polycrystalline quartz consists of multiple smaller quartz crystals fused together, offering a cost-effective alternative to monocrystalline quartz with slightly lower purity and efficiency levels. This structure often results in a less uniform appearance and a higher density of grain boundaries, impacting the material's mechanical strength and electrical properties. Polycrystalline quartz is widely used in applications demanding durability and thermal stability, such as in electronic components and optical devices, where its polycrystalline nature enhances certain performance characteristics.

Crystal Structure Differences

Monocrystalline quartz features a continuous and uniform crystal lattice, resulting in higher purity and consistent physical properties across the material. Polycrystalline quartz consists of multiple small quartz crystals fused together, creating grain boundaries that can affect its mechanical strength and optical clarity. These structural differences impact their respective applications in electronics and optics, where monocrystalline quartz is preferred for precision and stability.

Physical and Mechanical Properties Comparison

Monocrystalline quartz exhibits superior mechanical strength and higher hardness, typically around 7 on the Mohs scale, compared to polycrystalline quartz, which has a slightly lower hardness due to grain boundaries. Physically, monocrystalline quartz features a uniform crystal structure with enhanced thermal stability and lower internal stress, while polycrystalline quartz consists of multiple crystalline grains resulting in increased grain boundaries that can reduce thermal and mechanical performance. The density of monocrystalline quartz is generally consistent at approximately 2.65 g/cm3, whereas polycrystalline quartz may exhibit minor variations due to porosity and grain orientation.

Optical and Electrical Properties

Monocrystalline quartz exhibits superior optical clarity and higher piezoelectric efficiency due to its uniform crystal lattice, making it ideal for precision oscillators and high-frequency applications. Polycrystalline quartz, composed of multiple crystallites, has lower optical transparency and reduced electrical uniformity, causing greater energy losses and signal distortion. These distinctions affect their performance in devices such as resonators, sensors, and electronic filters where optical and electrical properties are critical.

Manufacturing Processes for Each Type

Monocrystalline quartz is manufactured through the hydrothermal growth process, where a single seed crystal is subjected to high temperature and pressure in a nutrient-rich solution, resulting in a uniform crystal lattice. Polycrystalline quartz, on the other hand, is produced by melting and recrystallizing quartz powder, forming multiple small crystals that are fused together, which creates grain boundaries within the material. These distinct manufacturing processes significantly influence the physical properties and applications of each quartz type, with monocrystalline quartz offering superior purity and electronic performance.

Applications in Industry and Technology

Monocrystalline quartz, known for its uniform crystal lattice, is widely used in high-precision electronic components such as oscillators and resonators in the telecommunications and aerospace industries due to its superior piezoelectric properties. Polycrystalline quartz, composed of multiple crystal grains, is preferred in applications requiring mechanical strength and durability, including optical instruments, pressure sensors, and cutting tools in manufacturing. Both forms are essential in semiconductor wafer production, with monocrystalline quartz enabling better electronic performance and polycrystalline quartz offering cost-effective versatility in device packaging and insulation.

Advantages and Limitations of Each Quartz Type

Monocrystalline quartz offers superior purity and consistency, resulting in enhanced optical clarity and better electronic performance, but it is costlier and more challenging to produce in large sizes. Polycrystalline quartz provides improved structural strength and is more affordable due to its simpler manufacturing process, yet it exhibits lower homogeneity and slightly reduced electronic quality compared to its monocrystalline counterpart. Selecting between monocrystalline and polycrystalline quartz depends on application-specific requirements for clarity, strength, cost, and performance.

Choosing the Right Quartz Material for Your Needs

Monocrystalline quartz offers higher purity and superior electrical properties, making it ideal for precision electronic components and frequency control devices. Polycrystalline quartz, composed of multiple crystal grains, provides cost-effective durability suitable for general industrial applications requiring thermal stability. Selecting the right quartz material depends on balancing performance requirements, budget constraints, and the specific application environment.

Monocrystalline Quartz vs Polycrystalline Quartz Infographic

materialdif.com

materialdif.com