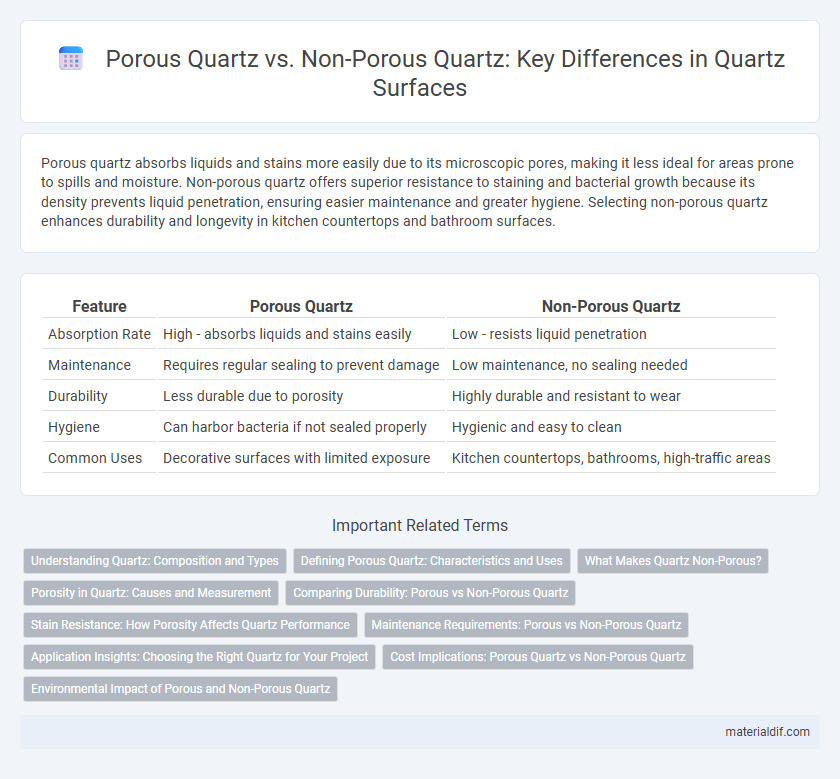

Porous quartz absorbs liquids and stains more easily due to its microscopic pores, making it less ideal for areas prone to spills and moisture. Non-porous quartz offers superior resistance to staining and bacterial growth because its density prevents liquid penetration, ensuring easier maintenance and greater hygiene. Selecting non-porous quartz enhances durability and longevity in kitchen countertops and bathroom surfaces.

Table of Comparison

| Feature | Porous Quartz | Non-Porous Quartz |

|---|---|---|

| Absorption Rate | High - absorbs liquids and stains easily | Low - resists liquid penetration |

| Maintenance | Requires regular sealing to prevent damage | Low maintenance, no sealing needed |

| Durability | Less durable due to porosity | Highly durable and resistant to wear |

| Hygiene | Can harbor bacteria if not sealed properly | Hygienic and easy to clean |

| Common Uses | Decorative surfaces with limited exposure | Kitchen countertops, bathrooms, high-traffic areas |

Understanding Quartz: Composition and Types

Porous quartz contains microscopic voids that can absorb liquids and stains, making it less durable for certain applications compared to non-porous quartz, which is dense and impermeable. Non-porous quartz, engineered by combining natural quartz crystals with resin and pigments, offers superior resistance to moisture, bacteria, and staining, ideal for kitchen countertops and high-traffic surfaces. Understanding the distinction between porous and non-porous quartz is essential for selecting the appropriate material based on durability, maintenance, and intended use.

Defining Porous Quartz: Characteristics and Uses

Porous quartz features a network of interconnected pores that allow fluids and gases to pass through, making it highly valuable in filtration, catalysis, and oil recovery applications. This microporous structure enhances surface area and adsorption capacity, distinguishing it from non-porous quartz, which lacks such permeability and is typically used in optical and electronic devices. The unique characteristics of porous quartz enable its use in advanced environmental and industrial processes requiring efficient fluid flow and chemical interaction.

What Makes Quartz Non-Porous?

Quartz becomes non-porous due to its dense crystalline structure formed through the fusion of silicon dioxide molecules, which eliminates microscopic gaps and pores. This compact arrangement prevents water, stains, and bacteria from penetrating the surface, making non-porous quartz highly resistant to damage and easy to maintain. Industrial processes like high-pressure compression and polymer resin bonding further enhance quartz's non-porosity by sealing any natural fissures present in the raw material.

Porosity in Quartz: Causes and Measurement

Porosity in quartz significantly influences its physical properties and applications, with porous quartz containing microscopic voids or pores formed due to incomplete crystal growth or environmental factors during formation. These pores affect quartz's density, permeability, and surface area, making porous quartz suitable for filtration and catalytic applications, whereas non-porous quartz offers greater durability and chemical resistance for use in electronics and optics. Measurement of porosity in quartz typically involves techniques such as mercury intrusion porosimetry, gas adsorption methods like BET analysis, and advanced imaging technologies like scanning electron microscopy (SEM) to quantify pore size distribution and volume.

Comparing Durability: Porous vs Non-Porous Quartz

Porous quartz tends to absorb moisture and stains more easily, compromising its long-term durability, especially in high-traffic or wet environments. Non-porous quartz offers superior resistance to bacteria, stains, and liquids, making it more durable for kitchen countertops and bathroom surfaces. The inherent density of non-porous quartz enhances its structural integrity, reducing the risk of cracks and surface degradation over time.

Stain Resistance: How Porosity Affects Quartz Performance

Porous quartz surfaces absorb liquids more readily, making them susceptible to staining from substances like wine, coffee, and oils, while non-porous quartz resists stains effectively due to its dense composition. The reduced porosity in engineered quartz enhances stain resistance by preventing liquid penetration into the material. Selecting non-porous quartz for countertops ensures easier maintenance and longer-lasting aesthetic appeal in high-use kitchen environments.

Maintenance Requirements: Porous vs Non-Porous Quartz

Porous quartz requires more frequent sealing and careful cleaning to prevent stains and bacterial growth, while non-porous quartz surfaces resist staining and microbial penetration without additional treatments. Maintenance of porous quartz involves using pH-balanced cleaners and avoiding harsh chemicals to preserve the surface integrity. Non-porous quartz offers a low-maintenance solution, as its dense structure repels liquids, dirt, and oils, making routine cleaning simpler and less time-consuming.

Application Insights: Choosing the Right Quartz for Your Project

Porous quartz offers increased breathability and moisture absorption, making it ideal for industrial filtration and specialized scientific equipment where fluid interaction is crucial. Non-porous quartz provides superior chemical resistance and durability, preferred in countertops, laboratory surfaces, and electronics where impermeability prevents contamination and enhances longevity. Selecting the right quartz depends on balancing permeability requirements with durability needs specific to your project environment.

Cost Implications: Porous Quartz vs Non-Porous Quartz

Porous quartz tends to be more cost-effective due to its lower manufacturing complexity and availability in natural forms, making it a budget-friendly option for various applications. Non-porous quartz, often engineered with advanced sealing and compaction techniques, commands a higher price because of its enhanced durability and resistance to staining and moisture. Businesses and homeowners should weigh these cost implications against performance needs, as non-porous quartz may reduce long-term maintenance expenses despite the initial higher investment.

Environmental Impact of Porous and Non-Porous Quartz

Porous quartz absorbs water and chemicals more readily, increasing the risk of contamination and environmental harm during manufacturing and disposal. Non-porous quartz resists moisture and chemical infiltration, reducing pollutant release and enhancing durability, which lowers environmental impact over its lifecycle. Choosing non-porous quartz supports sustainability by minimizing harmful emissions and waste generation in construction and industrial applications.

Porous Quartz vs Non-Porous Quartz Infographic

materialdif.com

materialdif.com