Pure quartz is a naturally occurring crystalline form of silicon dioxide known for its high chemical purity and exceptional hardness. Fused quartz is produced by melting natural quartz sand at extremely high temperatures, resulting in a non-crystalline, amorphous glass with superior thermal and optical properties. The key difference lies in structure, where pure quartz is crystalline and fused quartz is amorphous, affecting their applications in electronics, optics, and high-temperature environments.

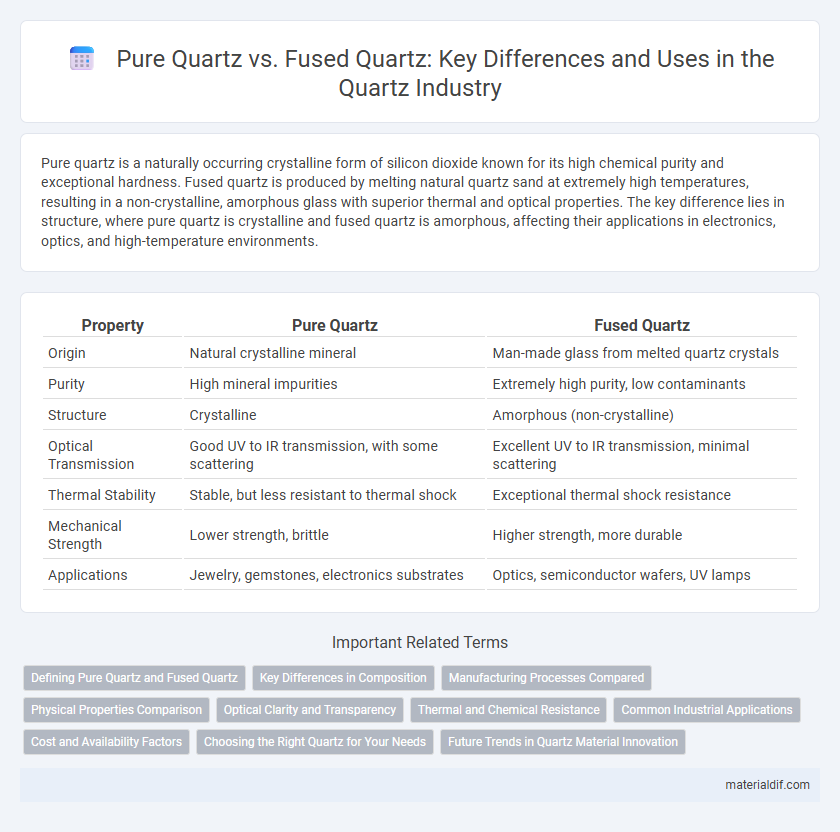

Table of Comparison

| Property | Pure Quartz | Fused Quartz |

|---|---|---|

| Origin | Natural crystalline mineral | Man-made glass from melted quartz crystals |

| Purity | High mineral impurities | Extremely high purity, low contaminants |

| Structure | Crystalline | Amorphous (non-crystalline) |

| Optical Transmission | Good UV to IR transmission, with some scattering | Excellent UV to IR transmission, minimal scattering |

| Thermal Stability | Stable, but less resistant to thermal shock | Exceptional thermal shock resistance |

| Mechanical Strength | Lower strength, brittle | Higher strength, more durable |

| Applications | Jewelry, gemstones, electronics substrates | Optics, semiconductor wafers, UV lamps |

Defining Pure Quartz and Fused Quartz

Pure quartz is a naturally occurring crystalline form of silicon dioxide (SiO2) characterized by its high purity and ordered atomic structure, commonly used in optical and electronic applications. Fused quartz, also known as fused silica, is a non-crystalline amorphous solid produced by melting high-purity quartz crystals at extremely high temperatures, resulting in a material with superior thermal stability and optical clarity. Both materials exhibit excellent chemical resistance and mechanical strength, but fused quartz offers enhanced homogeneity and reduced internal stress, making it ideal for precision instruments and high-performance optical components.

Key Differences in Composition

Pure quartz is a naturally occurring crystalline form of silicon dioxide (SiO2) with a consistent atomic structure, while fused quartz is manufactured through the melting and rapid cooling of high-purity quartz sand to form an amorphous, non-crystalline solid. Compositionally, pure quartz retains a well-ordered lattice structure, contributing to its optical clarity and mechanical strength. Fused quartz lacks the crystalline order, resulting in enhanced thermal shock resistance and lower impurity levels compared to natural pure quartz.

Manufacturing Processes Compared

Pure quartz is naturally occurring crystalline silicon dioxide, typically mined and processed through crushing and purification methods to remove impurities, ensuring high purity and structural integrity. Fused quartz, on the other hand, is manufactured by melting high-purity quartz crystal or sand at extremely high temperatures, usually above 1700degC, followed by rapid cooling to produce an amorphous, non-crystalline glass with superior thermal shock resistance. This manufacturing process of fused quartz allows for enhanced uniformity and reduced internal stress compared to the crystalline structure of pure quartz, making it ideal for applications requiring extreme thermal stability and optical clarity.

Physical Properties Comparison

Pure quartz exhibits a crystalline structure with high hardness (7 on the Mohs scale) and excellent thermal stability, maintaining integrity up to 573degC before phase transition. Fused quartz, an amorphous form of silicon dioxide produced by melting pure quartz, has superior optical transparency, lower thermal expansion (0.5 x 10-6 /degC), and greater resistance to thermal shock compared to crystalline pure quartz. Both materials have high chemical purity, but fused quartz is preferred in applications requiring minimized thermal distortion and enhanced mechanical strength.

Optical Clarity and Transparency

Pure quartz exhibits high optical clarity and excellent transparency due to its natural crystalline structure, making it ideal for precision optical applications. Fused quartz, produced by melting and rapidly cooling high-purity quartz, offers exceptional uniformity and minimal impurities, resulting in enhanced optical clarity and superior transparency across a wide spectral range. The homogeneity of fused quartz ensures reduced birefringence and low light scattering compared to pure quartz, optimizing its performance in high-precision optics and photonics.

Thermal and Chemical Resistance

Pure quartz exhibits exceptional thermal stability with a melting point around 1,710degC, making it highly resistant to heat and thermal shock, whereas fused quartz, produced by melting natural quartz, shows enhanced uniformity and fewer impurities that improve its resistance to thermal expansion and cracking. Chemically, both pure and fused quartz demonstrate excellent resistance to most acids and alkalis, but fused quartz offers superior purity levels, reducing the risk of chemical contamination in sensitive applications. These properties make fused quartz ideal for high-precision environments requiring strict thermal and chemical durability, while pure quartz remains valuable for its natural crystalline structure.

Common Industrial Applications

Pure quartz, primarily composed of natural crystalline silicon dioxide, excels in applications requiring high thermal stability and optical clarity, such as precision optics, semiconductor wafers, and UV lamps. Fused quartz, created by melting natural quartz at high temperatures to form a non-crystalline glass, is widely used in manufacturing crucibles, high-temperature windows, and photolithography equipment due to its superior thermal shock resistance and purity. Both materials underpin critical industries including electronics, aerospace, and lighting, where durability, chemical inertness, and optical properties are paramount.

Cost and Availability Factors

Pure quartz is naturally occurring and generally more abundant, making it more cost-effective for large-scale industrial applications. Fused quartz, created by melting natural quartz to remove impurities, commands a higher price due to its superior purity, thermal stability, and optical clarity. Limited production capacity and energy-intensive manufacturing contribute to fused quartz's higher cost and more restricted availability compared to pure quartz.

Choosing the Right Quartz for Your Needs

Pure quartz is a naturally occurring crystalline form of silicon dioxide (SiO2), valued for its high thermal stability and optical clarity in applications like electronics and optics. Fused quartz, produced by melting natural quartz at high temperatures, offers superior thermal shock resistance and low thermal expansion, making it ideal for high-precision industrial processes and laboratory equipment. Selecting the right quartz depends on specific requirements such as temperature tolerance, mechanical strength, and optical properties, with pure quartz favored for natural purity and fused quartz chosen for enhanced durability and controlled properties.

Future Trends in Quartz Material Innovation

Future trends in quartz material innovation emphasize enhanced durability and thermal stability, with pure quartz maintaining high purity for advanced optics and electronics applications. Fused quartz developments focus on reducing impurities and improving homogeneity to meet stringent semiconductor manufacturing requirements. Emerging research explores hybrid quartz composites combining properties of pure and fused quartz for next-generation photonics and aerospace technologies.

Pure Quartz vs Fused Quartz Infographic

materialdif.com

materialdif.com