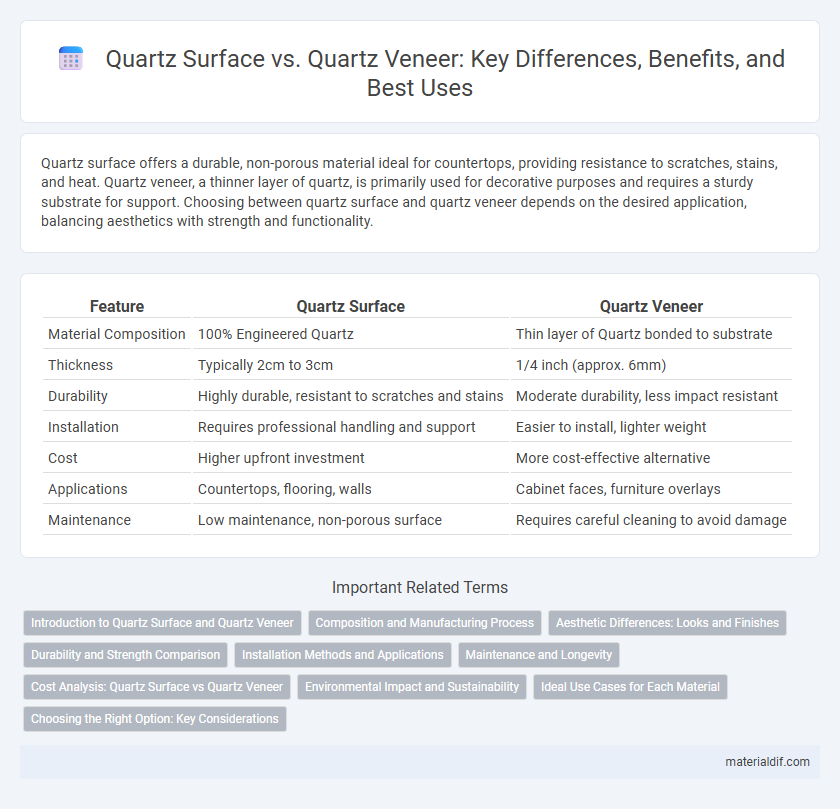

Quartz surface offers a durable, non-porous material ideal for countertops, providing resistance to scratches, stains, and heat. Quartz veneer, a thinner layer of quartz, is primarily used for decorative purposes and requires a sturdy substrate for support. Choosing between quartz surface and quartz veneer depends on the desired application, balancing aesthetics with strength and functionality.

Table of Comparison

| Feature | Quartz Surface | Quartz Veneer |

|---|---|---|

| Material Composition | 100% Engineered Quartz | Thin layer of Quartz bonded to substrate |

| Thickness | Typically 2cm to 3cm | 1/4 inch (approx. 6mm) |

| Durability | Highly durable, resistant to scratches and stains | Moderate durability, less impact resistant |

| Installation | Requires professional handling and support | Easier to install, lighter weight |

| Cost | Higher upfront investment | More cost-effective alternative |

| Applications | Countertops, flooring, walls | Cabinet faces, furniture overlays |

| Maintenance | Low maintenance, non-porous surface | Requires careful cleaning to avoid damage |

Introduction to Quartz Surface and Quartz Veneer

Quartz surfaces, made from engineered stone composed of approximately 90-95% natural quartz and resin binders, offer exceptional durability, resistance to scratches, stains, and heat, making them ideal for countertops and flooring. Quartz veneer, a thinner layer of engineered quartz, provides similar visual aesthetics and durability benefits but is designed for applications requiring lighter weight and easier installation, such as wall cladding and backsplashes. Both materials combine natural quartz's hardness with advanced manufacturing techniques, offering modern, low-maintenance options for interior design.

Composition and Manufacturing Process

Quartz surfaces consist primarily of 90-95% natural quartz crystals combined with resin binders and pigments, engineered through a high-pressure and high-temperature process to create a durable, non-porous slab. Quartz veneers are thinner, flexible sheets made by bonding crushed quartz particles with adhesives onto a backing material, allowing lightweight application on surfaces without the bulk of full quartz slabs. The manufacturing process of quartz surfaces involves compacting and curing the mixture to achieve high density and strength, while quartz veneers use lamination techniques to maintain flexibility and ease of installation.

Aesthetic Differences: Looks and Finishes

Quartz surfaces deliver a uniform, non-porous finish with consistent color and pattern, making them ideal for sleek countertops and modern kitchen designs. Quartz veneers, being thinner, often exhibit more natural stone-like variations and textures, enhancing depth and character while maintaining a lightweight structure. The choice between quartz surface and veneer hinges on desired visual impact and application, with surfaces offering polished perfection and veneers providing authentic stone aesthetics.

Durability and Strength Comparison

Quartz surfaces are engineered with a high concentration of natural quartz crystals, making them exceptionally durable and resistant to scratches, stains, and heat. Quartz veneer, a thinner layer primarily used for aesthetic enhancement, lacks the same structural strength and durability as full quartz surfaces. When comparing longevity and resistance to damage, quartz surfaces consistently outperform quartz veneers in both commercial and residential applications.

Installation Methods and Applications

Quartz surfaces are typically installed as thick slabs, requiring precise measurement, cutting, and professional adhesive application for countertops and flooring, providing durability and a seamless look. Quartz veneer consists of thin quartz layers applied over existing surfaces using strong adhesives, offering a lightweight and cost-effective solution primarily for wall cladding and decorative panels. Installation of quartz veneer is less labor-intensive and faster, suitable for renovation projects where minimal structural modification is desired.

Maintenance and Longevity

Quartz surfaces provide superior durability and require minimal maintenance, offering resistance to scratches, stains, and heat. Quartz veneers, being thinner, are more susceptible to damage and may need more frequent care to maintain their appearance. The longevity of quartz surfaces significantly outperforms veneers due to their robust composition and thicker construction.

Cost Analysis: Quartz Surface vs Quartz Veneer

Quartz surfaces typically cost between $50 and $100 per square foot due to their durability and full slab thickness, while quartz veneers are generally priced lower, around $30 to $60 per square foot, reflecting their thinner profile and reduced material usage. Installation costs for quartz surfaces tend to be higher because of their weight and complexity, whereas quartz veneers offer savings with easier handling and quicker application. Long-term value favors quartz surfaces for higher durability and resistance, potentially offsetting the initial cost difference when factoring in maintenance and replacement.

Environmental Impact and Sustainability

Quartz surfaces consist primarily of natural quartz crystals combined with resins, resulting in a durable, low-maintenance product with a longer lifespan and lower replacement frequency, which contributes to reduced environmental impact over time. Quartz veneers use thinner layers of quartz bonded to substrates, requiring less raw material extraction but often involving adhesives and substrates with higher environmental footprints, potentially affecting recyclability and overall sustainability. The sustainability of quartz surfaces depends on factors such as the sourcing of raw materials, manufacturing energy consumption, and end-of-life recyclability, with thicker quartz surfaces generally offering better durability and reduced environmental burden compared to quartz veneers.

Ideal Use Cases for Each Material

Quartz surfaces are highly durable and non-porous, making them ideal for kitchen countertops, bathroom vanities, and high-traffic areas where resistance to scratches, stains, and heat is essential. Quartz veneer, being a thinner and lighter version, is suited for wall cladding, furniture accents, and decorative applications where weight savings and ease of installation are priorities. Both materials offer versatility and aesthetic appeal, but quartz surface is preferred for heavy-duty use while quartz veneer excels in design-focused, lightweight installations.

Choosing the Right Option: Key Considerations

Quartz surface offers a durable and scratch-resistant choice ideal for countertops and high-traffic areas, while quartz veneer provides a thinner, lightweight option suitable for cladding and decorative applications. Key considerations include thickness, installation complexity, cost, and intended use, with quartz surface ensuring better durability and quartz veneer offering versatility and ease of application. Evaluating durability needs, budget constraints, and aesthetic preferences helps determine the optimal option between quartz surface and quartz veneer.

Quartz Surface vs Quartz Veneer Infographic

materialdif.com

materialdif.com