Quartz porosity refers to the presence of tiny pores or voids within the quartz structure, allowing fluids or gases to pass through or be stored. Non-porous quartz lacks these spaces, resulting in a dense, impermeable material commonly used in applications requiring durability and chemical resistance. The distinction between porous and non-porous quartz significantly impacts its use in filtration, construction, and ornamental purposes.

Table of Comparison

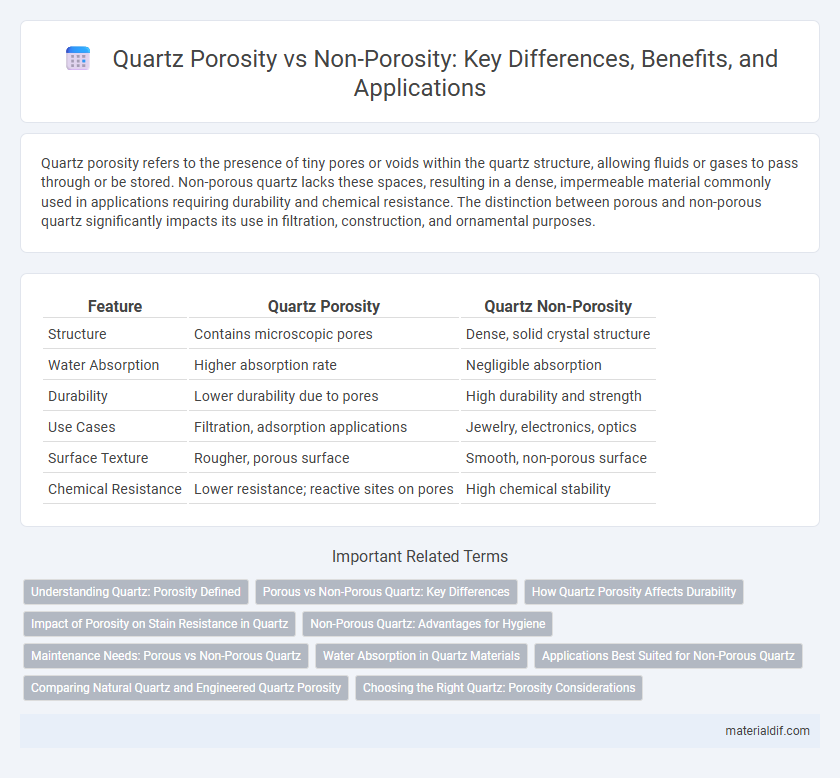

| Feature | Quartz Porosity | Quartz Non-Porosity |

|---|---|---|

| Structure | Contains microscopic pores | Dense, solid crystal structure |

| Water Absorption | Higher absorption rate | Negligible absorption |

| Durability | Lower durability due to pores | High durability and strength |

| Use Cases | Filtration, adsorption applications | Jewelry, electronics, optics |

| Surface Texture | Rougher, porous surface | Smooth, non-porous surface |

| Chemical Resistance | Lower resistance; reactive sites on pores | High chemical stability |

Understanding Quartz: Porosity Defined

Quartz porosity refers to the presence of microscopic voids or pores within quartz crystals that can influence fluid storage and permeability in geological formations. Non-porous quartz lacks these internal spaces, resulting in a dense structure with minimal fluid retention capacity. Understanding quartz porosity is crucial for applications in hydrocarbon reservoirs and groundwater aquifers, where permeability directly impacts extraction efficiency and resource management.

Porous vs Non-Porous Quartz: Key Differences

Porous quartz contains microscopic voids or pores that can absorb fluids, making it less dense and more reactive to environmental factors, while non-porous quartz is compact with minimal to no void spaces, resulting in higher durability and resistance to staining. Porous quartz often requires sealing to prevent damage and maintain structural integrity, whereas non-porous quartz is naturally resistant to moisture and easier to clean. The distinction between porous and non-porous quartz significantly impacts its applications in construction, countertops, and optical devices.

How Quartz Porosity Affects Durability

Quartz porosity significantly influences its durability by determining the mineral's resistance to weathering and mechanical stress. Higher porosity in quartz increases the likelihood of fluid infiltration and microfracture development, which can weaken the crystal structure over time. In contrast, non-porous quartz exhibits enhanced strength and longevity due to its compact, impermeable nature, making it highly resistant to degradation in various environmental conditions.

Impact of Porosity on Stain Resistance in Quartz

Quartz porosity plays a critical role in determining stain resistance, with non-porous quartz exhibiting superior resistance due to its dense, compact surface that prevents liquid absorption. Porous quartz allows liquids and oils to penetrate, increasing susceptibility to staining and requiring more frequent sealing and maintenance. Therefore, low or non-porous quartz surfaces are preferred in high-use areas to ensure durable stain resistance and ease of cleaning.

Non-Porous Quartz: Advantages for Hygiene

Non-porous quartz surfaces resist bacteria and mold growth due to their dense, impermeable structure, making them ideal for maintaining high hygiene standards. Unlike porous materials, non-porous quartz prevents liquid absorption, reducing the risk of staining and contamination. This durability and easy-to-clean nature make non-porous quartz a preferred choice for kitchens, hospitals, and laboratories where sanitation is critical.

Maintenance Needs: Porous vs Non-Porous Quartz

Porous quartz surfaces require frequent sealing and specialized cleaning to prevent stains and bacteria buildup, increasing long-term maintenance efforts. Non-porous quartz, by contrast, resists moisture and contaminants naturally, allowing for easier cleaning with mild detergents and less frequent upkeep. The low porosity in engineered quartz enhances durability and reduces the risk of mold, making it ideal for kitchens and bathrooms with minimal maintenance needs.

Water Absorption in Quartz Materials

Quartz porosity significantly influences water absorption rates, with porous quartz materials exhibiting higher water retention due to their interconnected pore networks. Non-porous quartz demonstrates minimal water absorption, making it ideal for applications requiring low moisture uptake and high durability. Understanding the porosity-water absorption relationship in quartz aids in selecting the appropriate material for construction, filtration, and decorative uses.

Applications Best Suited for Non-Porous Quartz

Non-porous quartz is highly valued in applications requiring extreme durability and low maintenance, such as kitchen countertops and bathroom surfaces, due to its resistance to stains, bacteria, and moisture infiltration. Its dense structure prevents liquid absorption, making it ideal for environments with high hygiene standards like hospitals and commercial kitchens. Non-porous quartz surfaces also excel in industrial settings where chemical resistance and ease of cleaning are critical.

Comparing Natural Quartz and Engineered Quartz Porosity

Natural quartz exhibits low porosity due to its dense crystalline structure, which limits fluid absorption and enhances durability in geological contexts. Engineered quartz, while also designed with minimal porosity, incorporates resins and pigments that fill micro-pores, resulting in a more uniform, nearly non-porous surface ideal for countertops and sanitary applications. The controlled porosity in engineered quartz reduces susceptibility to staining and bacterial growth compared to natural quartz, making it preferable for hygiene-sensitive environments.

Choosing the Right Quartz: Porosity Considerations

Quartz porosity plays a crucial role in determining its suitability for various applications, with porous quartz exhibiting higher water absorption and potential staining risks compared to non-porous quartz, which offers superior durability and resistance to moisture. Selecting the right quartz depends on the intended use; non-porous quartz is ideal for countertops and surfaces requiring minimal maintenance and hygiene, while porous quartz may be suitable for decorative or less exposed installations. Understanding the porosity levels, typically measured by water absorption rates below 0.5% for non-porous and above 0.5% for porous quartz, ensures optimal performance and longevity.

Quartz Porosity vs Non-porosity Infographic

materialdif.com

materialdif.com