Sintered quartz is created by fusing fine quartz particles under high temperature and pressure, resulting in a highly durable and non-porous surface ideal for industrial applications and high-performance countertops. Pressed quartz involves compressing quartz particles with resin binders, producing a dense, uniform material often used in residential countertops with enhanced stain resistance and aesthetic appeal. The key difference lies in sintered quartz's superior heat resistance and structural integrity compared to the resin-based composition of pressed quartz, which offers more design versatility but less durability.

Table of Comparison

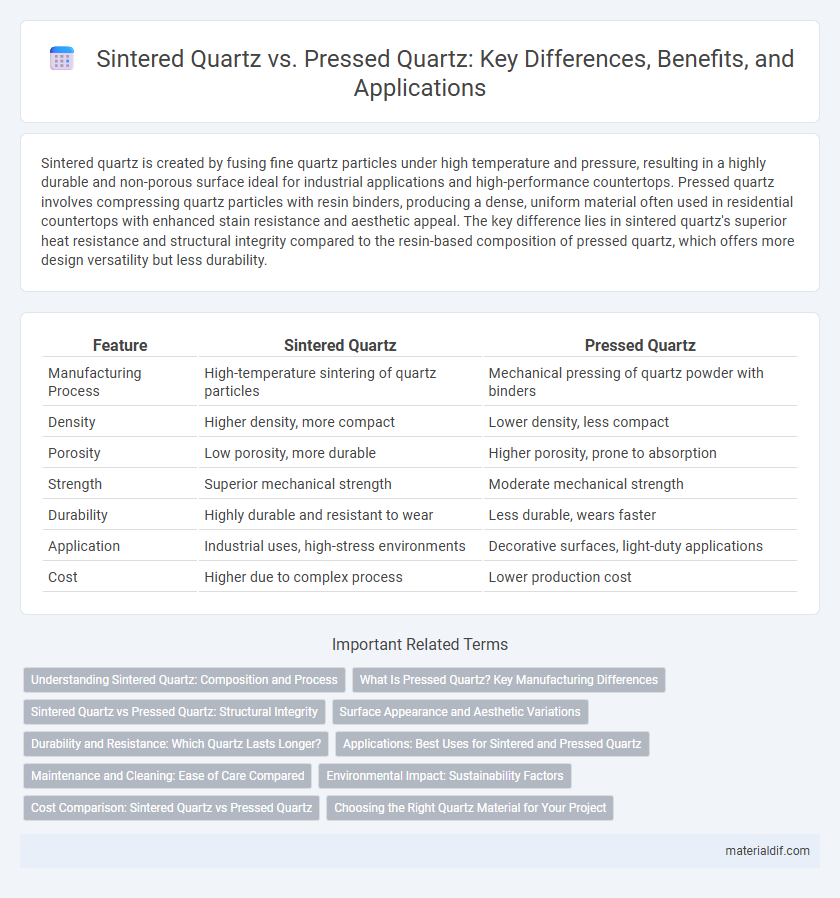

| Feature | Sintered Quartz | Pressed Quartz |

|---|---|---|

| Manufacturing Process | High-temperature sintering of quartz particles | Mechanical pressing of quartz powder with binders |

| Density | Higher density, more compact | Lower density, less compact |

| Porosity | Low porosity, more durable | Higher porosity, prone to absorption |

| Strength | Superior mechanical strength | Moderate mechanical strength |

| Durability | Highly durable and resistant to wear | Less durable, wears faster |

| Application | Industrial uses, high-stress environments | Decorative surfaces, light-duty applications |

| Cost | Higher due to complex process | Lower production cost |

Understanding Sintered Quartz: Composition and Process

Sintered quartz is composed of high-purity quartz particles fused under extreme heat and pressure without melting, resulting in a dense, homogeneous material with exceptional thermal stability and chemical resistance. The sintering process involves compacting quartz powders in a mold and heating them just below their melting point, which preserves the crystalline structure while eliminating porosity. This method produces quartz with superior mechanical strength and precision, making it suitable for advanced industrial applications compared to pressed quartz, which is typically less uniform and mechanically weaker.

What Is Pressed Quartz? Key Manufacturing Differences

Pressed quartz is an engineered material created by compressing quartz particles mixed with resins and pigments under high pressure and heat, resulting in a dense and uniform surface. Unlike sintered quartz, which involves fusing quartz particles at extremely high temperatures without binders, pressed quartz relies on resin binders to hold the material together. This manufacturing difference leads pressed quartz to offer enhanced design flexibility and a wider range of colors but may exhibit lower heat resistance compared to sintered quartz.

Sintered Quartz vs Pressed Quartz: Structural Integrity

Sintered quartz exhibits superior structural integrity compared to pressed quartz due to its manufacturing process, which involves fusing fine quartz particles at high temperatures to create a dense, homogeneous material. Pressed quartz, formed by compressing quartz powder under pressure, tends to have higher porosity and lower mechanical strength, making it more susceptible to fractures. The enhanced durability and thermal resistance of sintered quartz make it ideal for applications requiring robust, long-lasting quartz components.

Surface Appearance and Aesthetic Variations

Sintered quartz offers a more uniform and consistent surface appearance due to its high-temperature fabrication process, resulting in finer grain structures and smoother finishes. Pressed quartz exhibits greater aesthetic variations with visible veins and color swirls, providing a more natural stone-like look preferred in decorative applications. Surface textures of sintered quartz tend to be matte or satin, while pressed quartz allows for a wider range of gloss levels and customizable patterns.

Durability and Resistance: Which Quartz Lasts Longer?

Sintered quartz exhibits superior durability and resistance compared to pressed quartz due to its manufacturing process involving high-pressure and high-temperature fusion of silica particles. This results in greater structural integrity, enhanced resistance to chipping, scratching, and thermal shock, making sintered quartz ideal for high-traffic surfaces. Pressed quartz, while still durable, may be more prone to wear and damage over time due to its lower-density composition and less rigorous fabrication methods.

Applications: Best Uses for Sintered and Pressed Quartz

Sintered quartz, known for its high purity and strength, is ideal for semiconductor manufacturing, optical components, and laboratory equipment due to its excellent thermal stability and resistance to chemical corrosion. Pressed quartz, with its cost-effective production and sufficient durability, suits applications in decorative countertops, tiles, and household surfaces where aesthetic appeal and moderate wear resistance are required. Selecting between sintered and pressed quartz depends on balancing performance needs with budget constraints in industrial versus commercial and residential environments.

Maintenance and Cleaning: Ease of Care Compared

Sintered quartz surfaces offer exceptional durability and resistance to stains, requiring minimal maintenance with just regular cleaning using mild soap and water. Pressed quartz, while also durable, may demand more careful upkeep to prevent surface scratches and avoid harsh chemicals that can degrade resin binders. Both materials benefit from routine wiping to maintain their aesthetic appeal, but sintered quartz's non-porous structure ensures easier, more effective cleaning over time.

Environmental Impact: Sustainability Factors

Sintered quartz exhibits lower environmental impact due to its production process that uses natural quartz and minimal additives, resulting in less chemical waste and energy consumption compared to pressed quartz. Pressed quartz often incorporates resin binders, which can release volatile organic compounds (VOCs) and complicate recycling efforts. Sustainability factors favor sintered quartz for its longer lifespan and superior recyclability, minimizing landfill contribution and resource depletion.

Cost Comparison: Sintered Quartz vs Pressed Quartz

Sintered quartz generally incurs higher costs than pressed quartz due to its complex manufacturing process involving high-temperature sintering of finely ground quartz particles, resulting in superior density and mechanical properties. Pressed quartz, produced by compressing quartz particles under lower pressure and temperature, offers a more cost-effective option but with reduced strength and durability. The price difference reflects the enhanced performance of sintered quartz in industrial applications requiring greater thermal stability and wear resistance.

Choosing the Right Quartz Material for Your Project

Sintered quartz offers superior thermal stability and chemical resistance, making it ideal for high-performance applications and demanding environments. Pressed quartz, while more affordable and easier to shape, suits decorative or low-stress projects where extreme durability is not critical. Selecting the right quartz material depends on balancing project requirements like mechanical strength, thermal conductivity, and budget constraints.

Sintered Quartz vs Pressed Quartz Infographic

materialdif.com

materialdif.com