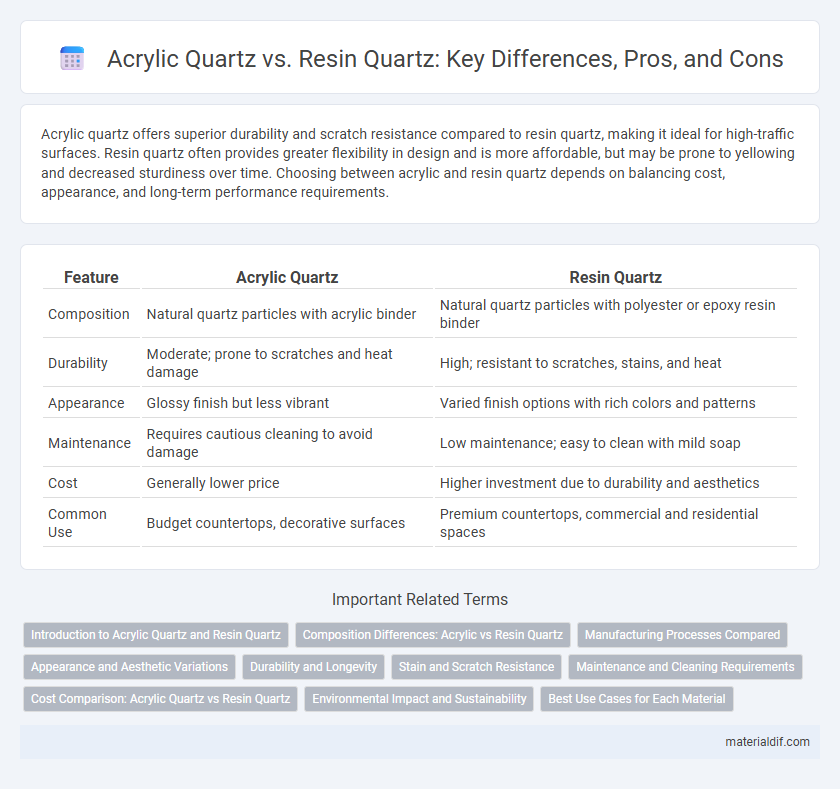

Acrylic quartz offers superior durability and scratch resistance compared to resin quartz, making it ideal for high-traffic surfaces. Resin quartz often provides greater flexibility in design and is more affordable, but may be prone to yellowing and decreased sturdiness over time. Choosing between acrylic and resin quartz depends on balancing cost, appearance, and long-term performance requirements.

Table of Comparison

| Feature | Acrylic Quartz | Resin Quartz |

|---|---|---|

| Composition | Natural quartz particles with acrylic binder | Natural quartz particles with polyester or epoxy resin binder |

| Durability | Moderate; prone to scratches and heat damage | High; resistant to scratches, stains, and heat |

| Appearance | Glossy finish but less vibrant | Varied finish options with rich colors and patterns |

| Maintenance | Requires cautious cleaning to avoid damage | Low maintenance; easy to clean with mild soap |

| Cost | Generally lower price | Higher investment due to durability and aesthetics |

| Common Use | Budget countertops, decorative surfaces | Premium countertops, commercial and residential spaces |

Introduction to Acrylic Quartz and Resin Quartz

Acrylic quartz combines natural quartz crystals with acrylic resin, creating a durable, non-porous surface ideal for countertops and flooring. Resin quartz is made by blending natural quartz particles with epoxy or polyester resin, offering enhanced strength and resistance to staining compared to traditional materials. Both materials provide versatile, low-maintenance options, but acrylic quartz tends to offer a smoother finish while resin quartz delivers greater durability.

Composition Differences: Acrylic vs Resin Quartz

Acrylic quartz consists primarily of natural quartz crystals bonded with an acrylic polymer, resulting in a lightweight, durable surface with enhanced flexibility. Resin quartz is composed of crushed quartz particles embedded in a synthetic resin matrix, which provides superior hardness and scratch resistance compared to acrylic-based composites. The distinct bonding agents--acrylic polymer versus resin--impact the material's heat resistance, durability, and application suitability in countertops and decorative surfaces.

Manufacturing Processes Compared

Acrylic quartz is produced by blending acrylic resin with natural quartz aggregates through a heat polymerization process, resulting in a highly durable, non-porous surface ideal for countertops. Resin quartz, however, relies on a mixture of polyester or epoxy resins combined with quartz aggregates, cured under controlled heat and pressure to achieve a dense, engineered stone. The key manufacturing difference lies in the type of resin and polymerization technique, impacting the final product's strength, flexibility, and resistance to heat and stains.

Appearance and Aesthetic Variations

Acrylic quartz offers a vibrant, glossy finish with rich color depth and a more uniform appearance, making it ideal for intricate patterns and bold design choices. Resin quartz presents a softer sheen and can mimic natural stone textures with subtle variations, catering to classic or understated aesthetics. Both materials provide diverse color palettes and patterns, but acrylic quartz excels in vivid, polished looks while resin quartz leans toward natural, muted tones.

Durability and Longevity

Acrylic quartz offers superior durability compared to resin quartz due to its higher resistance to scratches, impacts, and heat, making it ideal for high-traffic surfaces. Resin quartz, while cost-effective and visually versatile, tends to degrade faster under prolonged exposure to UV light and heavy use, limiting its longevity. Choosing acrylic quartz ensures a longer-lasting surface with minimal maintenance in demanding environments.

Stain and Scratch Resistance

Acrylic quartz exhibits moderate stain resistance but is less durable against scratches compared to resin quartz, which features a denser composition with enhanced scratch resistance and better protection against staining. Resin quartz surfaces maintain their appearance longer due to superior hardness and non-porous qualities, preventing discoloration and surface damage from everyday use. Choosing resin quartz is ideal for high-traffic areas requiring robust stain and scratch resistance without frequent maintenance.

Maintenance and Cleaning Requirements

Acrylic quartz surfaces demand regular cleaning with mild soap and water to prevent scratching and maintain their glossy finish. Resin quartz, known for its durability, requires minimal maintenance but benefits from wiping with a damp cloth and non-abrasive cleaners to avoid discoloration. Both materials resist stains effectively, yet avoiding harsh chemicals ensures long-lasting beauty and structural integrity in quartz countertops.

Cost Comparison: Acrylic Quartz vs Resin Quartz

Acrylic quartz typically costs less than resin quartz due to the lower price of acrylic materials and simpler manufacturing processes. Resin quartz, while more expensive, offers enhanced durability and a higher-quality finish, justifying its premium cost. Cost differences between acrylic and resin quartz often influence budget decisions in interior design and construction projects.

Environmental Impact and Sustainability

Acrylic quartz, composed primarily of natural quartz combined with acrylic resin, offers a more sustainable option due to its lower energy consumption in production compared to resin quartz, which relies heavily on petroleum-based polymers. The recyclability of acrylic quartz is higher, reducing landfill waste, whereas resin quartz poses challenges in biodegradability and chemical pollution during manufacturing. Choosing acrylic quartz supports environmental preservation through reduced carbon footprint and enhanced material durability, aligning with sustainable construction practices.

Best Use Cases for Each Material

Acrylic quartz offers exceptional clarity and is ideal for decorative applications, such as countertops and bathroom vanities, where visual appeal is paramount. Resin quartz provides superior durability and resistance to heat and chemicals, making it best suited for high-traffic areas and industrial environments. Selecting between acrylic and resin quartz depends on balancing aesthetic requirements with functional performance needs.

Acrylic Quartz vs Resin Quartz Infographic

materialdif.com

materialdif.com