High-purity quartz offers superior chemical and optical properties essential for advanced applications like semiconductor manufacturing and optical fibers. Industrial quartz, while abundant and cost-effective, contains impurities that limit its use to construction, glassmaking, and foundry operations. Choosing high-purity quartz ensures enhanced performance and reliability in precision technologies where material consistency is critical.

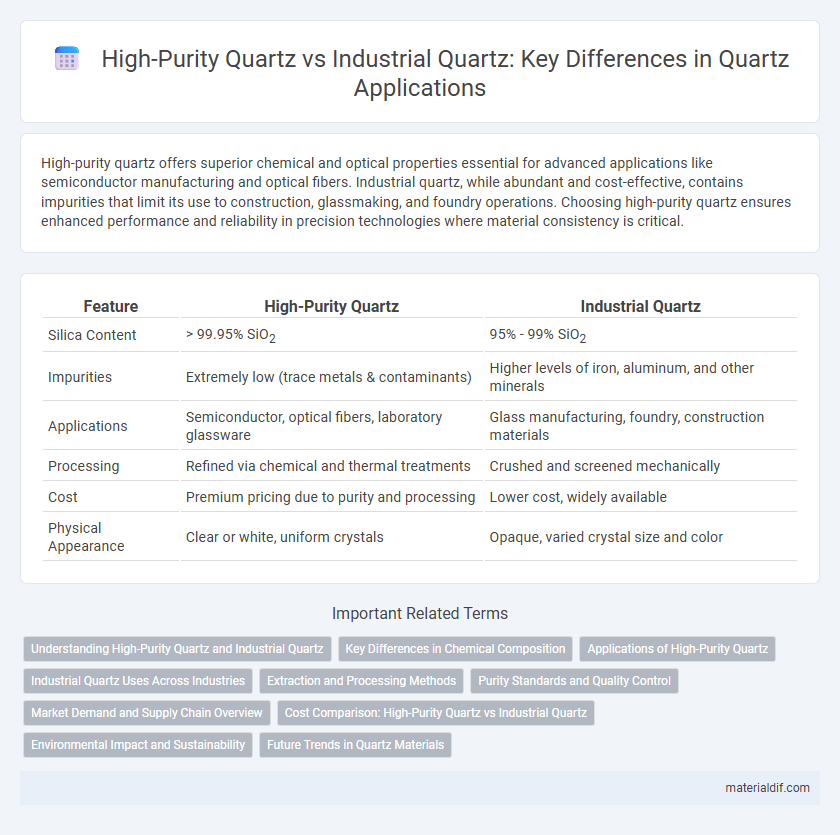

Table of Comparison

| Feature | High-Purity Quartz | Industrial Quartz |

|---|---|---|

| Silica Content | > 99.95% SiO2 | 95% - 99% SiO2 |

| Impurities | Extremely low (trace metals & contaminants) | Higher levels of iron, aluminum, and other minerals |

| Applications | Semiconductor, optical fibers, laboratory glassware | Glass manufacturing, foundry, construction materials |

| Processing | Refined via chemical and thermal treatments | Crushed and screened mechanically |

| Cost | Premium pricing due to purity and processing | Lower cost, widely available |

| Physical Appearance | Clear or white, uniform crystals | Opaque, varied crystal size and color |

Understanding High-Purity Quartz and Industrial Quartz

High-purity quartz contains over 99.99% silicon dioxide (SiO2), making it essential for semiconductor manufacturing, optical fibers, and laboratory equipment where contamination must be minimized. Industrial quartz, with purity levels typically between 95% and 98%, is widely used in glassmaking, foundry molds, and construction materials due to its excellent physical properties and cost-effectiveness. Understanding the differences in purity, crystalline structure, and application environments helps optimize material selection for specific industrial processes.

Key Differences in Chemical Composition

High-purity quartz primarily consists of silicon dioxide (SiO2) with minimal impurities, often exceeding 99.99% purity, making it ideal for semiconductor and optical applications. Industrial quartz contains higher levels of impurities such as iron, aluminum, and titanium, which impact its suitability for specialized uses and reduce its overall purity level. The key chemical composition difference lies in the trace elemental content, directly affecting the material's performance in high-tech industries versus general manufacturing.

Applications of High-Purity Quartz

High-purity quartz, characterized by its silica content exceeding 99.99%, is essential in semiconductor manufacturing, photovoltaic cells, and optical fibers due to its exceptional purity and minimal trace elements. This type of quartz ensures superior performance in electronic devices by reducing contamination and enhancing reliability in microchip production. In contrast, industrial quartz with lower purity is primarily used in construction, glass making, and foundry applications where ultra-high purity is not critical.

Industrial Quartz Uses Across Industries

Industrial quartz, valued for its durability and cost-efficiency, is extensively used in manufacturing, electronics, and construction sectors. It serves as a critical component in glassmaking, silicon metal production, and as filler material in paints and rubber. Its physical properties support applications in ceramics, foundry molds, and hydraulic fracturing, driving diverse industrial processes worldwide.

Extraction and Processing Methods

High-purity quartz extraction involves meticulous selection and mining of quartz with minimal impurities, often sourced from geologically stable regions, ensuring high silicon dioxide content above 99.99%. Processing methods for high-purity quartz include advanced chemical purification techniques such as acid leaching and high-temperature thermal treatment to remove contaminants like iron, aluminum, and titanium. In contrast, industrial quartz, used in construction and manufacturing, requires less rigorous extraction and basic crushing and grinding processes, as its purity standards are lower, typically around 95% to 99% silicon dioxide.

Purity Standards and Quality Control

High-purity quartz exceeds 99.99% silicon dioxide content, requiring rigorous quality control processes to meet stringent purity standards essential for semiconductor and optical applications. Industrial quartz typically contains 95-99% silicon dioxide, with allowable impurities tailored for construction or metallurgical uses where ultra-high purity is not critical. Advanced analytical techniques such as ICP-MS and XRD ensure consistent purity levels and detect trace contaminants, distinguishing high-purity quartz from industrial-grade materials.

Market Demand and Supply Chain Overview

High-purity quartz commands premium market demand due to its critical role in semiconductor manufacturing, solar panels, and specialty glass industries, requiring stringent purity levels above 99.99% SiO2. Industrial quartz, with lower purity levels typically between 95-98% SiO2, serves in construction, foundry, and chemical sectors where high-grade specifications are less critical but volume demand remains significant. The supply chain for high-purity quartz is tightly controlled, involving advanced beneficiation and refining processes, whereas industrial quartz benefits from abundant natural deposits and simpler processing, causing distinct supply dynamics and pricing models in global markets.

Cost Comparison: High-Purity Quartz vs Industrial Quartz

High-purity quartz commands a significantly higher price than industrial quartz due to its superior chemical composition and lower impurity levels, essential for semiconductor and optical applications. The cost disparity stems from advanced processing techniques required to achieve the high purity, driving up production expenses compared to the more readily available industrial quartz used primarily in construction and glassmaking. Companies prioritize high-purity quartz for specialized technology sectors despite the premium cost, whereas industrial quartz offers a cost-effective solution for large-scale, less sensitive manufacturing needs.

Environmental Impact and Sustainability

High-purity quartz, primarily used in semiconductor and solar industries, requires extensive purification processes that consume significant energy but generate fewer pollutants compared to industrial quartz mining. Industrial quartz extraction often leads to habitat disruption, dust emissions, and higher water usage, raising environmental concerns over sustainability. Advances in recycling and responsible sourcing methodologies enhance the sustainability profile of both quartz types by reducing waste and minimizing ecological footprints.

Future Trends in Quartz Materials

High-purity quartz, characterized by silica content above 99.99%, drives advanced semiconductor and photovoltaic industries, while industrial quartz with purity levels around 95-99% remains pivotal for glassmaking and foundry applications. Future trends indicate increasing demand for ultra-high-purity quartz due to evolving requirements in microelectronics and solar panel manufacturing, emphasizing innovations in refining and processing technologies. Growth in sustainable production methods and recycling of quartz materials also plays a crucial role in addressing environmental concerns and supply chain stability in the quartz market.

High-Purity Quartz vs Industrial Quartz Infographic

materialdif.com

materialdif.com