Quartz offers superior durability and non-porous properties compared to ceramic, making it highly resistant to stains and scratches. Ceramic is more heat-resistant but tends to chip or crack under heavy impact, whereas quartz surfaces combine natural stone beauty with enhanced strength due to engineered resin binders. For kitchen countertops, quartz provides easier maintenance and longer-lasting aesthetic appeal than ceramic options.

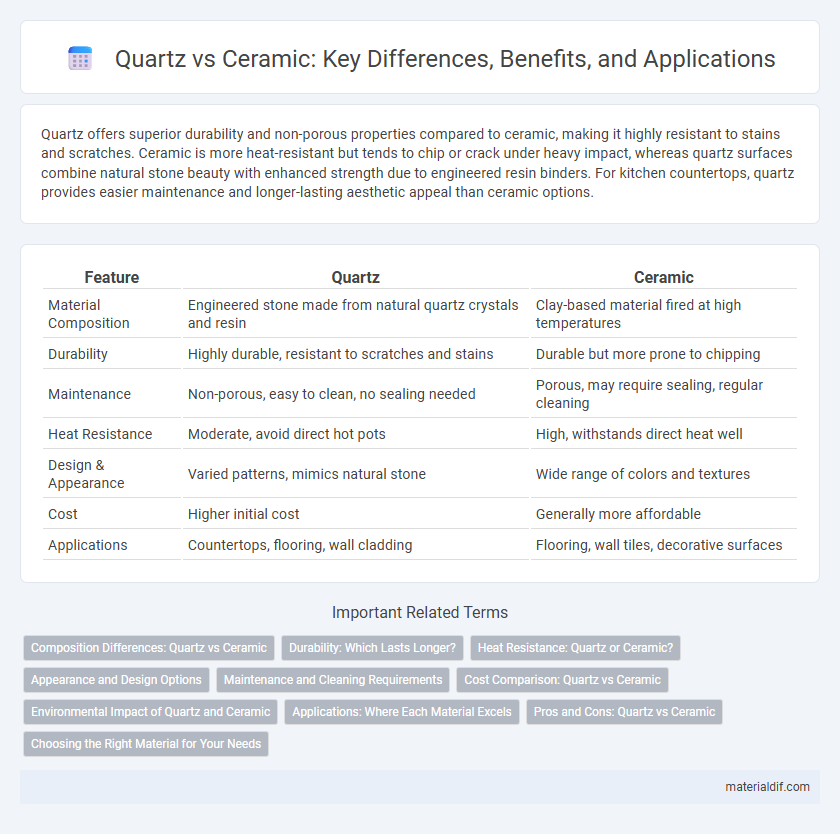

Table of Comparison

| Feature | Quartz | Ceramic |

|---|---|---|

| Material Composition | Engineered stone made from natural quartz crystals and resin | Clay-based material fired at high temperatures |

| Durability | Highly durable, resistant to scratches and stains | Durable but more prone to chipping |

| Maintenance | Non-porous, easy to clean, no sealing needed | Porous, may require sealing, regular cleaning |

| Heat Resistance | Moderate, avoid direct hot pots | High, withstands direct heat well |

| Design & Appearance | Varied patterns, mimics natural stone | Wide range of colors and textures |

| Cost | Higher initial cost | Generally more affordable |

| Applications | Countertops, flooring, wall cladding | Flooring, wall tiles, decorative surfaces |

Composition Differences: Quartz vs Ceramic

Quartz surfaces are engineered from about 90% natural quartz crystals combined with resin binders and pigments, resulting in a durable and non-porous material ideal for countertops. Ceramic tiles are primarily composed of natural clay and minerals, fired at high temperatures to achieve hardness and resistance, but lack the resin component found in quartz composites. The resin content in quartz enhances its flexibility and stain resistance, distinguishing it from the brittle and porous structure of ceramic materials.

Durability: Which Lasts Longer?

Quartz surfaces, composed of 90% natural quartz crystals combined with resin, offer exceptional durability and resistance to scratches, chips, and stains, making them highly suitable for high-traffic areas. Ceramic, typically fired clay, is also durable but is generally more prone to chipping and cracking under heavy impact or sharp objects. Quartz's non-porous structure provides enhanced longevity and requires less maintenance compared to ceramic, which may absorb stains and degrade over time if not properly sealed.

Heat Resistance: Quartz or Ceramic?

Ceramic materials exhibit superior heat resistance compared to quartz, withstanding temperatures above 1200degC without damage. Quartz, primarily composed of silicon dioxide, begins to soften and degrade around 573degC, limiting its use in high-heat applications. Therefore, ceramic is the preferred choice for environments requiring exposure to extreme heat due to its enhanced thermal stability.

Appearance and Design Options

Quartz offers a wide range of vibrant colors and consistent patterns due to its engineered composition, making it ideal for contemporary and uniform designs. Ceramic tends to feature more natural and earthy tones, often mimicking stone or clay textures, which appeals to those seeking rustic or traditional aesthetics. Both materials provide versatile design options, but quartz allows for greater customization in sheen and style, enhancing modern interior appeal.

Maintenance and Cleaning Requirements

Quartz surfaces require minimal maintenance due to their non-porous nature, making them resistant to stains and bacteria without the need for sealing. Ceramic countertops, while also durable, may need periodic sealing to prevent moisture absorption and staining. Both materials can be cleaned effectively with mild soap and water, but quartz offers enhanced ease of cleaning and long-term hygiene benefits.

Cost Comparison: Quartz vs Ceramic

Quartz countertops typically range from $50 to $150 per square foot, offering a mid-to-high price point due to engineered materials and durability. Ceramic countertops generally cost between $30 and $60 per square foot, making them a budget-friendly option with a natural, porous surface. The cost difference reflects quartz's enhanced resistance to staining and scratches, while ceramic appeals to cost-sensitive projects seeking aesthetic versatility.

Environmental Impact of Quartz and Ceramic

Quartz surfaces offer a lower environmental impact compared to ceramic tiles due to their longer lifespan and reduced need for replacement, minimizing waste accumulation. Manufacturing quartz requires less energy and produces fewer emissions than ceramic production, which involves high-temperature kilns and significant resource consumption. Recycled content in quartz countertops further reduces environmental footprint, contrasting with ceramics that often lack sustainable material integration.

Applications: Where Each Material Excels

Quartz excels in kitchen countertops and bathroom vanities due to its non-porous, stain-resistant surface and superior durability against heat and scratches. Ceramic is preferred for wall tiles, backsplashes, and decorative accents, offering excellent moisture resistance and a wide range of design options with vibrant colors and patterns. Both materials perform well in high-traffic areas, but quartz's strength makes it ideal for heavy-use surfaces, while ceramic's versatility suits aesthetic-driven applications.

Pros and Cons: Quartz vs Ceramic

Quartz countertops offer exceptional durability and resistance to scratches and stains due to their engineered composition, making them ideal for high-traffic kitchens. Ceramic surfaces, while highly heat resistant and available in a wide variety of colors and designs, tend to be more brittle and prone to chipping. Quartz requires less maintenance and is non-porous, thereby resisting bacteria and mold, whereas ceramic tiles may need grouting upkeep and can harbor dirt in grout lines.

Choosing the Right Material for Your Needs

Quartz offers a non-porous surface with high durability and low maintenance, making it ideal for kitchens and bathrooms prone to heavy use and spills. Ceramic provides excellent heat resistance and versatility at a lower cost, suitable for areas with less frequent wear or decorative applications. Evaluating factors such as budget, durability needs, and maintenance preferences helps determine whether quartz's engineered strength or ceramic's natural hardness is the better choice for specific projects.

Quartz vs Ceramic Infographic

materialdif.com

materialdif.com