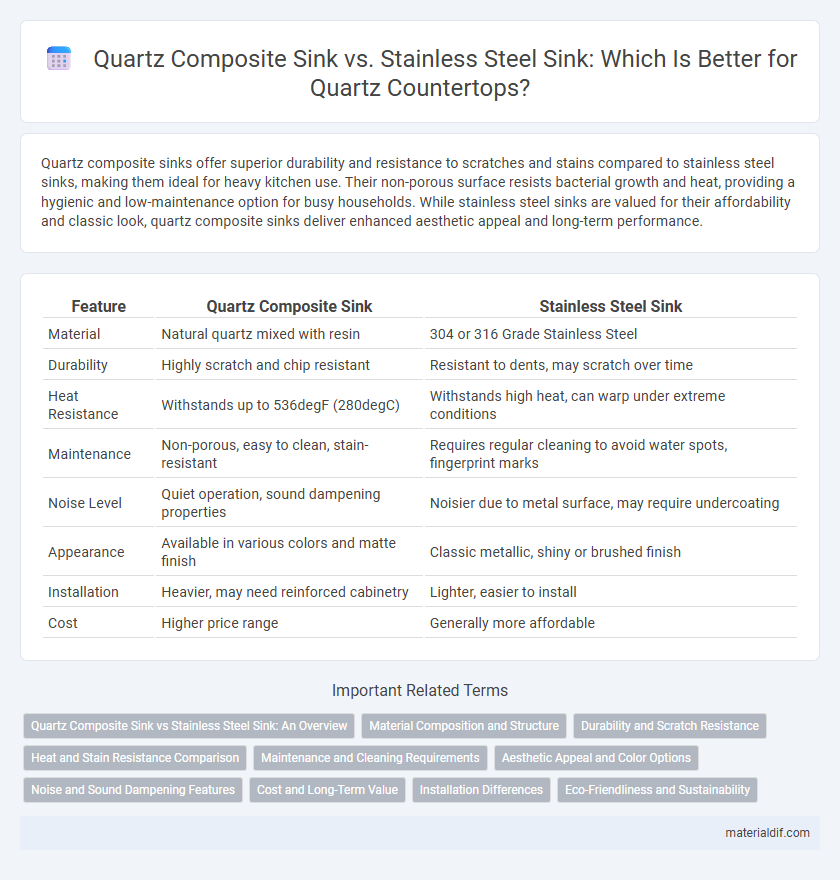

Quartz composite sinks offer superior durability and resistance to scratches and stains compared to stainless steel sinks, making them ideal for heavy kitchen use. Their non-porous surface resists bacterial growth and heat, providing a hygienic and low-maintenance option for busy households. While stainless steel sinks are valued for their affordability and classic look, quartz composite sinks deliver enhanced aesthetic appeal and long-term performance.

Table of Comparison

| Feature | Quartz Composite Sink | Stainless Steel Sink |

|---|---|---|

| Material | Natural quartz mixed with resin | 304 or 316 Grade Stainless Steel |

| Durability | Highly scratch and chip resistant | Resistant to dents, may scratch over time |

| Heat Resistance | Withstands up to 536degF (280degC) | Withstands high heat, can warp under extreme conditions |

| Maintenance | Non-porous, easy to clean, stain-resistant | Requires regular cleaning to avoid water spots, fingerprint marks |

| Noise Level | Quiet operation, sound dampening properties | Noisier due to metal surface, may require undercoating |

| Appearance | Available in various colors and matte finish | Classic metallic, shiny or brushed finish |

| Installation | Heavier, may need reinforced cabinetry | Lighter, easier to install |

| Cost | Higher price range | Generally more affordable |

Quartz Composite Sink vs Stainless Steel Sink: An Overview

Quartz composite sinks offer superior durability and scratch resistance compared to stainless steel sinks, making them ideal for heavy kitchen use. They provide a quieter and more heat-resistant surface, maintaining their aesthetic appeal over time with minimal maintenance. Stainless steel sinks, while more affordable and easier to install, often show water spots and dents, which quartz composites effectively resist due to their robust engineered material.

Material Composition and Structure

Quartz composite sinks combine natural quartz stone particles with durable resin binders, creating a dense and non-porous surface resistant to scratches and stains. Stainless steel sinks are made from alloyed steel compositions, primarily iron mixed with chromium and nickel, offering excellent corrosion resistance and a smooth, metallic finish. The composite's structure provides better heat retention and sound dampening compared to the thinner, more conductive stainless steel sinks.

Durability and Scratch Resistance

Quartz composite sinks offer superior durability due to their robust mixture of natural quartz and resin, making them highly resistant to chips and cracks compared to stainless steel sinks. Their non-porous surface enhances scratch resistance, maintaining a sleek appearance even after prolonged use. Stainless steel sinks, while durable, are more prone to dents and visible scratches, especially from heavy kitchenware.

Heat and Stain Resistance Comparison

Quartz composite sinks offer superior heat resistance, withstanding temperatures up to 536degF (280degC) without damage, compared to stainless steel sinks that can dent or discolor under extreme heat. Stain resistance in quartz composites is enhanced by non-porous surfaces that resist common household chemicals and discoloration, while stainless steel may show water spots and fingerprints more prominently. Both materials require proper care, but quartz composite sinks generally maintain appearance and durability longer in high-stain environments.

Maintenance and Cleaning Requirements

Quartz composite sinks require gentle cleaning with non-abrasive cloths and mild detergents to maintain their scratch-resistant, stain-proof surfaces, avoiding harsh chemicals that can damage resin binders. Stainless steel sinks demand regular wiping to prevent water spots and fingerprints, with occasional use of stainless steel polish to maintain their luster and resist corrosion. Both materials benefit from prompt removal of food residues and standing water to uphold durability and hygiene.

Aesthetic Appeal and Color Options

Quartz composite sinks offer a sleek, modern aesthetic with a smooth, matte finish that resists scratches and stains, making them a popular choice for contemporary kitchens. They come in a wide range of colors, including earthy tones like granite gray, onyx black, and sandy beige, allowing for greater customization to match various countertop materials. Stainless steel sinks provide a classic, industrial look with a shiny, reflective surface but typically offer limited color options, primarily silver and brushed nickel finishes.

Noise and Sound Dampening Features

Quartz composite sinks absorb sound more effectively due to their dense, non-metallic composition, significantly reducing noise from water impact and dish handling. Stainless steel sinks, typically thinner, tend to be noisier but can feature soundproofing pads or undercoatings to improve sound dampening. Choosing a quartz composite sink enhances kitchen acoustics with inherent noise-reduction properties, while stainless steel requires additional treatments for comparable sound control.

Cost and Long-Term Value

Quartz composite sinks generally cost more upfront than stainless steel sinks, with prices typically ranging from $300 to $700 compared to $150 to $400 for stainless steel. Despite the higher initial investment, quartz sinks offer superior durability and resist scratches, stains, and heat, contributing to greater long-term value. Stainless steel sinks may require more frequent repairs or replacement due to dents and scratches, potentially increasing overall costs over time.

Installation Differences

Quartz composite sinks require precise cutouts and additional support due to their heavier weight, making installation more complex than stainless steel sinks. Stainless steel sinks are lighter, easier to handle, and often come with pre-drilled holes, allowing for quicker, more straightforward installation. The durability of quartz composite also necessitates specialized sealants to prevent water damage during installation, unlike stainless steel sinks that use standard caulking methods.

Eco-Friendliness and Sustainability

Quartz composite sinks are crafted from a blend of natural quartz stone and resin, offering exceptional durability and resistance to scratches while being environmentally friendly due to the use of abundant natural materials and lower energy consumption during manufacturing. Stainless steel sinks, made from recyclable metal alloys, provide sustainability benefits by supporting a circular economy through easy recycling and long lifespan, but their production involves higher energy usage and environmental impact. Choosing between the two depends on prioritizing natural material composition and lower manufacturing emissions (quartz composite) versus recyclability and industrial durability (stainless steel).

Quartz Composite Sink vs Stainless Steel Sink Infographic

materialdif.com

materialdif.com