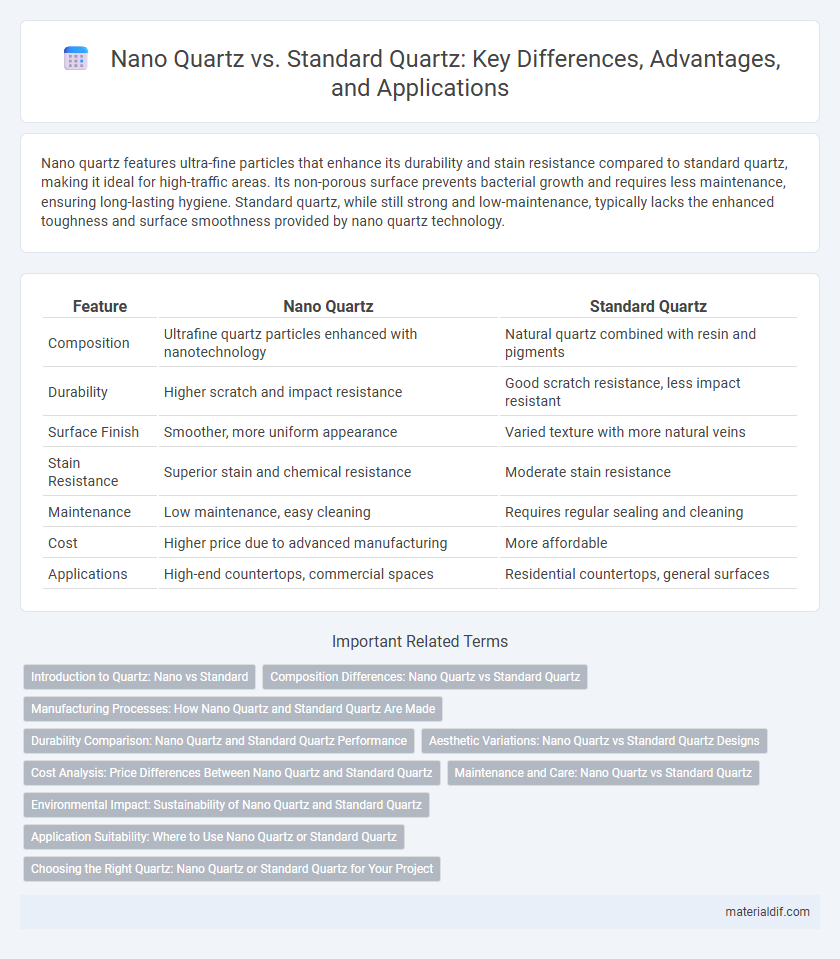

Nano quartz features ultra-fine particles that enhance its durability and stain resistance compared to standard quartz, making it ideal for high-traffic areas. Its non-porous surface prevents bacterial growth and requires less maintenance, ensuring long-lasting hygiene. Standard quartz, while still strong and low-maintenance, typically lacks the enhanced toughness and surface smoothness provided by nano quartz technology.

Table of Comparison

| Feature | Nano Quartz | Standard Quartz |

|---|---|---|

| Composition | Ultrafine quartz particles enhanced with nanotechnology | Natural quartz combined with resin and pigments |

| Durability | Higher scratch and impact resistance | Good scratch resistance, less impact resistant |

| Surface Finish | Smoother, more uniform appearance | Varied texture with more natural veins |

| Stain Resistance | Superior stain and chemical resistance | Moderate stain resistance |

| Maintenance | Low maintenance, easy cleaning | Requires regular sealing and cleaning |

| Cost | Higher price due to advanced manufacturing | More affordable |

| Applications | High-end countertops, commercial spaces | Residential countertops, general surfaces |

Introduction to Quartz: Nano vs Standard

Nano quartz features ultra-fine particles typically under 100 nanometers, resulting in enhanced surface smoothness and improved durability compared to standard quartz. Standard quartz consists of larger crystalline grains that provide a more granular texture but may be less resilient against scratches and stains. The nano-scale composition of nano quartz enables superior mechanical strength and stain resistance, making it ideal for high-performance applications in countertops and industrial surfaces.

Composition Differences: Nano Quartz vs Standard Quartz

Nano quartz incorporates ultra-fine silica particles, typically measuring less than 100 nanometers, which enhances its density and surface smoothness compared to standard quartz. Standard quartz contains larger crystalline silica fragments combined with resin and pigments, resulting in a coarser texture and less uniform surface. The nanoscale composition of nano quartz contributes to superior strength, scratch resistance, and a more consistent appearance in engineered stone surfaces.

Manufacturing Processes: How Nano Quartz and Standard Quartz Are Made

Nano Quartz is produced through advanced nanotechnology techniques that manipulate quartz particles at the molecular level to create a denser, more uniform material with enhanced durability and resistance to scratches. Standard Quartz, on the other hand, is manufactured by combining crushed natural quartz with resins and pigments, then curing the mixture under heat and pressure to form solid slabs. The precise control over particle size and bonding in Nano Quartz results in superior mechanical properties compared to the traditional manufacturing process of Standard Quartz.

Durability Comparison: Nano Quartz and Standard Quartz Performance

Nano quartz exhibits superior durability compared to standard quartz due to its enhanced nano-particle technology, which increases resistance to scratches, stains, and heat. This advanced composition results in a denser surface that withstands daily wear and tear more effectively, making it ideal for high-traffic areas. Standard quartz, while durable, is more prone to minor abrasions and surface damage over time, especially under constant heavy use.

Aesthetic Variations: Nano Quartz vs Standard Quartz Designs

Nano Quartz offers finer particle sizes that result in smoother textures and more vibrant colors compared to Standard Quartz. The enhanced uniformity of Nano Quartz allows for intricate, modern designs with greater detail and a higher gloss finish. Standard Quartz tends to have more natural, varied patterns and earthy tones, appealing to traditional aesthetic preferences.

Cost Analysis: Price Differences Between Nano Quartz and Standard Quartz

Nano quartz typically commands a higher price compared to standard quartz due to its advanced manufacturing process and enhanced durability features. The cost difference can range from 20% to 50%, influenced by brand reputation, thickness, and surface finish. Investment in nano quartz surfaces often yields long-term savings by reducing maintenance and replacement expenses.

Maintenance and Care: Nano Quartz vs Standard Quartz

Nano Quartz surfaces require less maintenance than standard quartz due to their enhanced resistance to stains, scratches, and bacterial growth. The nano-coatings applied to Nano Quartz reduce the need for frequent sealing and simplify routine cleaning with mild soap and water. Standard quartz demands periodic sealing and more careful handling to prevent damage and maintain its appearance over time.

Environmental Impact: Sustainability of Nano Quartz and Standard Quartz

Nano Quartz exhibits a reduced environmental footprint compared to Standard Quartz, owing to its enhanced efficiency in raw material usage and lower energy consumption during production. The sustainability of Nano Quartz is further supported by its longer lifespan and improved durability, minimizing the frequency of replacements and waste generation. Standard Quartz, while widely used, often requires higher energy inputs and produces more waste, making Nano Quartz a more eco-friendly alternative in surface material applications.

Application Suitability: Where to Use Nano Quartz or Standard Quartz

Nano Quartz offers superior durability and scratch resistance, making it ideal for high-traffic applications such as kitchen countertops and commercial surfaces. Standard Quartz, while still robust, suits residential installations like bathroom vanities and decorative wall cladding where intense wear is less frequent. Selecting Nano Quartz enhances longevity in demanding environments, whereas Standard Quartz balances cost and performance for everyday use.

Choosing the Right Quartz: Nano Quartz or Standard Quartz for Your Project

Nano quartz offers enhanced durability and stain resistance compared to standard quartz, making it ideal for high-traffic areas or surfaces exposed to harsh conditions. Standard quartz provides excellent aesthetic appeal with various patterns and colors, suitable for decorative applications where cost efficiency is a priority. Selecting between nano quartz and standard quartz depends on project requirements, balancing performance needs with budget and design preferences.

Nano Quartz vs Standard Quartz Infographic

materialdif.com

materialdif.com