Quartz agglomerate combines natural quartz particles with resin binders, resulting in a durable, non-porous surface ideal for countertops. Sintered stone, created by compressing natural minerals under high heat and pressure without resins, offers superior resistance to heat, scratches, and UV rays. Both materials provide aesthetic versatility, but sintered stone typically features enhanced durability and environmental sustainability compared to quartz agglomerate.

Table of Comparison

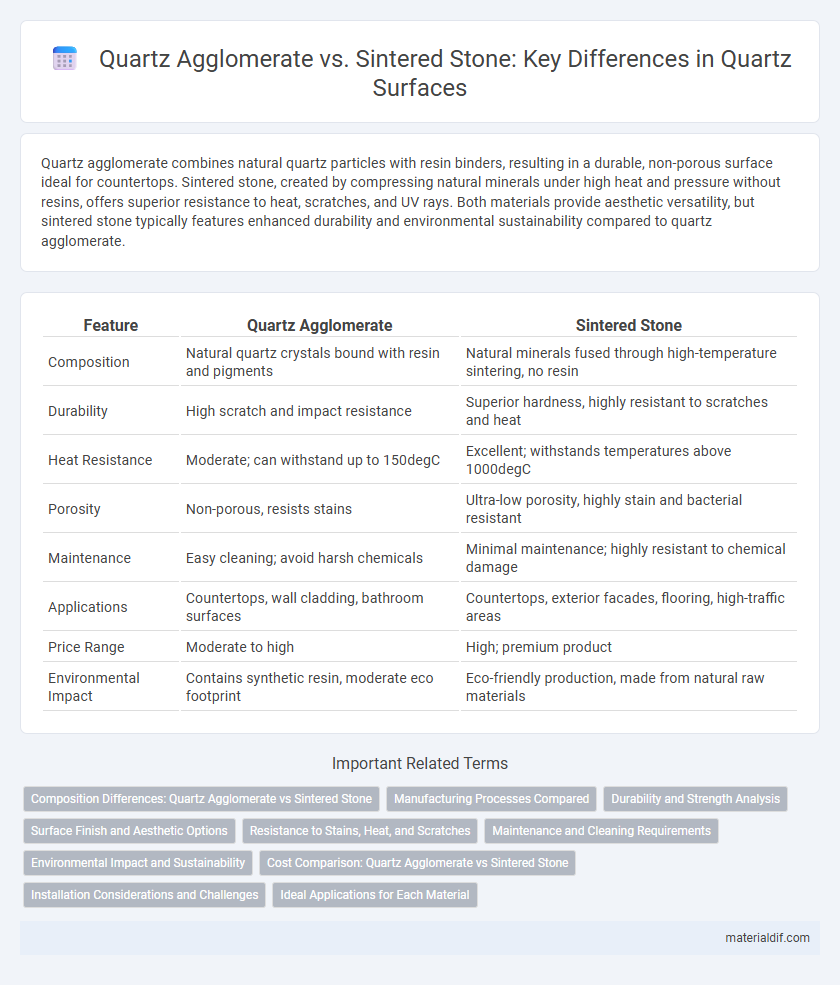

| Feature | Quartz Agglomerate | Sintered Stone |

|---|---|---|

| Composition | Natural quartz crystals bound with resin and pigments | Natural minerals fused through high-temperature sintering, no resin |

| Durability | High scratch and impact resistance | Superior hardness, highly resistant to scratches and heat |

| Heat Resistance | Moderate; can withstand up to 150degC | Excellent; withstands temperatures above 1000degC |

| Porosity | Non-porous, resists stains | Ultra-low porosity, highly stain and bacterial resistant |

| Maintenance | Easy cleaning; avoid harsh chemicals | Minimal maintenance; highly resistant to chemical damage |

| Applications | Countertops, wall cladding, bathroom surfaces | Countertops, exterior facades, flooring, high-traffic areas |

| Price Range | Moderate to high | High; premium product |

| Environmental Impact | Contains synthetic resin, moderate eco footprint | Eco-friendly production, made from natural raw materials |

Composition Differences: Quartz Agglomerate vs Sintered Stone

Quartz agglomerate primarily consists of natural quartz crystals mixed with resin binders and pigments, resulting in a non-porous, durable surface ideal for countertops. In contrast, sintered stone is manufactured by fusing natural minerals, including quartz, feldspar, and silica, under extreme heat and pressure without resins, creating a highly dense, scratch-resistant material. These compositional differences affect their heat resistance, porosity, and overall performance in various applications.

Manufacturing Processes Compared

Quartz agglomerate is manufactured by mixing crushed quartz with resin and pigments, then compressing the mixture under heat and pressure to form a durable surface. Sintered stone undergoes a process where natural minerals are exposed to extreme heat and pressure, causing particles to fuse without resins or binders, resulting in a highly dense and resistant material. The key difference lies in quartz agglomerate's reliance on synthetic resins, while sintered stone is produced through a purely mineral-based thermal fusion process.

Durability and Strength Analysis

Quartz agglomerate exhibits exceptional durability due to its high quartz content, typically around 90%, combined with resin binders that enhance impact resistance and reduce porosity. Sintered stone, produced through a high-temperature, high-pressure process without resins, offers superior hardness and scratch resistance, often outperforming quartz agglomerate in thermal and UV stability. While both materials provide robust strength for countertops and surfaces, sintered stone generally excels in resisting wear and extreme conditions, making it more durable in harsh environments.

Surface Finish and Aesthetic Options

Quartz agglomerate offers a wide range of surface finishes such as polished, matte, and leathered, providing versatile aesthetic options suitable for both modern and traditional interiors. Sintered stone surfaces feature highly durable finishes that resist scratching and staining, often showcasing natural stone patterns and textures with a more consistent appearance. Both materials deliver excellent visual appeal, but quartz agglomerate allows more customization in color and finish variations to match specific design preferences.

Resistance to Stains, Heat, and Scratches

Quartz agglomerate exhibits high resistance to stains and scratches due to its dense composition and resin binders, making it ideal for kitchen countertops exposed to daily wear. Sintered stone, created through high-temperature compression, offers superior heat resistance and durability, outperforming quartz agglomerate in withstanding direct contact with hot pots or pans. Both materials resist scratches effectively, but sintered stone's natural mineral composition enhances its longevity against abrasive damage and chemical stains.

Maintenance and Cleaning Requirements

Quartz agglomerate offers superior stain resistance and requires only mild soap and water for regular cleaning, reducing the risk of surface damage or discoloration. Sintered stone demands more careful maintenance, as its natural mineral composition can be sensitive to acidic or abrasive cleaners, necessitating pH-neutral cleaning agents. Both materials benefit from prompt spill removal, but quartz agglomerate generally provides easier, low-maintenance care for high-traffic surfaces.

Environmental Impact and Sustainability

Quartz agglomerate typically has a lower environmental impact due to the use of recycled quartz fragments and less energy-intensive manufacturing processes compared to sintered stone. Sintered stone requires higher temperatures and more resource-intensive raw materials, resulting in a larger carbon footprint. Sustainable quartz agglomerate options further promote eco-friendliness by incorporating recycled content and reducing waste during production.

Cost Comparison: Quartz Agglomerate vs Sintered Stone

Quartz agglomerate typically costs between $50 and $150 per square foot, making it a more budget-friendly option compared to sintered stone, which ranges from $70 to $200 per square foot due to its advanced manufacturing process. The price difference reflects the durability and heat resistance of sintered stone, often justifying the higher initial investment for commercial or high-traffic applications. Maintenance costs for quartz agglomerate are generally lower, but sintered stone offers better long-term value through its superior scratch and stain resistance.

Installation Considerations and Challenges

Quartz agglomerate typically requires professional installation due to its heavy weight and the need for precise cutting to prevent chipping, while sintered stone, being thinner and more flexible, allows for easier handling and installation in complex spaces. The porous nature of quartz agglomerate demands careful sealing and maintenance to avoid staining, contrasting with the non-porous, highly durable sintered stone that resists moisture and chemical damage without additional treatment. Installation challenges for quartz agglomerate include managing its brittleness and susceptibility to thermal shock, whereas sintered stone offers higher resistance to heat and impact, reducing risks during fitting and ensuring longevity in demanding environments.

Ideal Applications for Each Material

Quartz agglomerate offers exceptional durability and resistance to stains, making it ideal for kitchen countertops, bathroom vanities, and high-traffic surfaces requiring non-porous material. Sintered stone features superior heat resistance and UV stability, suited for outdoor applications, wall cladding, and commercial flooring where exposure to elements is frequent. Both materials provide aesthetic versatility, but quartz agglomerate excels indoors while sintered stone performs best in demanding environmental conditions.

Quartz Agglomerate vs Sintered Stone Infographic

materialdif.com

materialdif.com