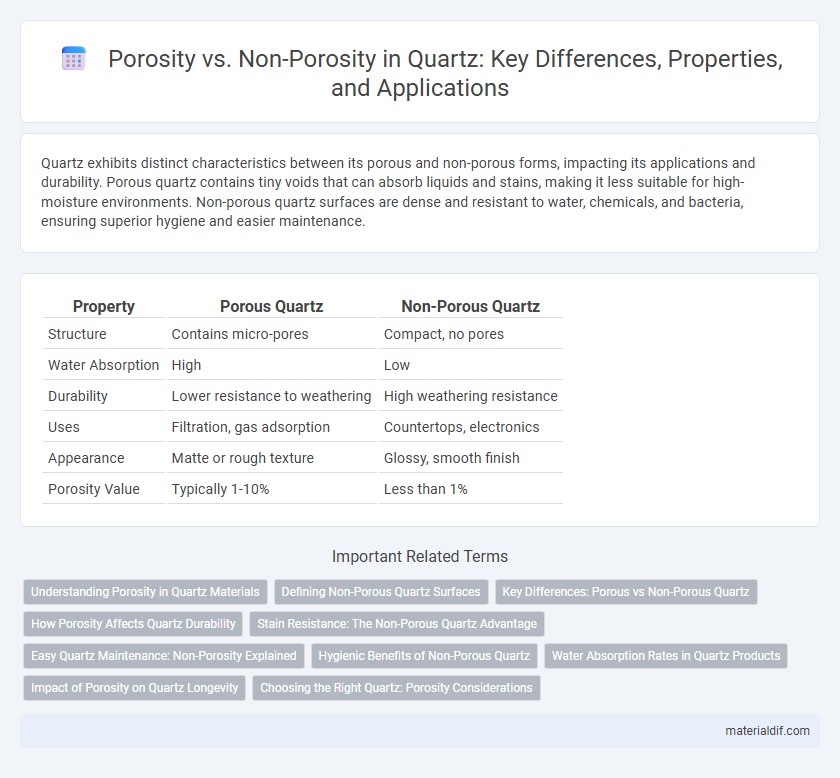

Quartz exhibits distinct characteristics between its porous and non-porous forms, impacting its applications and durability. Porous quartz contains tiny voids that can absorb liquids and stains, making it less suitable for high-moisture environments. Non-porous quartz surfaces are dense and resistant to water, chemicals, and bacteria, ensuring superior hygiene and easier maintenance.

Table of Comparison

| Property | Porous Quartz | Non-Porous Quartz |

|---|---|---|

| Structure | Contains micro-pores | Compact, no pores |

| Water Absorption | High | Low |

| Durability | Lower resistance to weathering | High weathering resistance |

| Uses | Filtration, gas adsorption | Countertops, electronics |

| Appearance | Matte or rough texture | Glossy, smooth finish |

| Porosity Value | Typically 1-10% | Less than 1% |

Understanding Porosity in Quartz Materials

Porosity in quartz materials significantly influences their physical properties, including strength, permeability, and durability. High porosity quartz contains numerous microscopic voids that can retain fluids, making it suitable for filtration and reservoir applications, whereas non-porous quartz exhibits low permeability and enhanced resistance to chemical and mechanical weathering. Understanding the degree of porosity aids in optimizing quartz for industrial uses such as electronics, construction, and hydrocarbon extraction.

Defining Non-Porous Quartz Surfaces

Non-porous quartz surfaces are characterized by their dense, impermeable structure that resists absorption of liquids, stains, and bacteria. Unlike porous materials, these engineered quartz surfaces are created through a process that tightly binds natural quartz crystals with resins and pigments, ensuring a smooth, sealed finish. This non-porosity enhances durability and hygiene, making quartz ideal for kitchen countertops and bathroom vanities where moisture resistance is critical.

Key Differences: Porous vs Non-Porous Quartz

Porous quartz contains tiny interconnected voids that allow fluids and gases to penetrate, affecting its durability and absorption properties, while non-porous quartz has a dense, impermeable structure that resists staining and chemical damage. Porous quartz is often used in filtration and catalysis due to its high surface area, whereas non-porous quartz is preferred in countertops and electronics for its strength and resistance to contamination. The key differences lie in their internal microstructure, impacting functionality, maintenance, and application suitability.

How Porosity Affects Quartz Durability

Quartz durability is significantly influenced by its porosity, with higher porosity leading to increased vulnerability to mechanical weathering and chemical degradation. Non-porous quartz exhibits enhanced resistance to abrasion and fracture due to its dense, compact crystal structure. Consequently, the lower the porosity, the greater the quartz's longevity in various environmental conditions, making non-porous quartz ideal for industrial applications requiring high durability.

Stain Resistance: The Non-Porous Quartz Advantage

Non-porous quartz surfaces exhibit superior stain resistance compared to porous materials due to their dense, impermeable structure that prevents liquids and oils from penetrating and causing discoloration. This inherent non-porosity eliminates the need for sealing, ensuring long-lasting durability and easier maintenance in kitchens and bathrooms. Quartz's resistance to stains from common substances like wine, coffee, and oils makes it the preferred choice for hygienic, stain-free countertops.

Easy Quartz Maintenance: Non-Porosity Explained

Quartz surfaces exhibit non-porosity, which means they do not absorb liquids or harbor bacteria, making maintenance straightforward and hygienic. Unlike porous materials such as natural stone, quartz resists staining and requires only simple cleaning with mild soap and water. This non-porous property ensures long-lasting durability and preserves the surface's pristine appearance with minimal effort.

Hygienic Benefits of Non-Porous Quartz

Non-porous quartz surfaces resist bacteria, mold, and mildew growth, ensuring higher hygienic standards in kitchens and bathrooms. Their impermeable structure prevents liquid absorption, reducing the risk of staining and contamination. This makes non-porous quartz an ideal choice for maintaining cleanliness and safety in food preparation and healthcare environments.

Water Absorption Rates in Quartz Products

Quartz products exhibit significantly lower water absorption rates in non-porous variants, typically below 0.05%, compared to porous counterparts that can absorb up to 0.5% water. This minimal water absorption in non-porous quartz enhances durability, stain resistance, and overall hygiene, making it ideal for kitchen countertops and bathroom surfaces. Porous quartz, although less common, may require additional sealing to prevent moisture penetration and potential damage over time.

Impact of Porosity on Quartz Longevity

Porosity in quartz significantly affects its longevity by increasing susceptibility to environmental factors such as moisture infiltration and chemical weathering. Non-porous quartz demonstrates enhanced durability and resistance to degradation, making it ideal for applications requiring long-term stability. The reduced pore spaces in non-porous quartz limit pathways for contaminants, thereby preserving structural integrity over extended periods.

Choosing the Right Quartz: Porosity Considerations

Choosing the right quartz for your application requires understanding porosity differences, as porous quartz absorbs liquids and stains more easily, affecting durability and maintenance. Non-porous quartz offers enhanced resistance to bacteria and moisture, making it ideal for kitchen countertops and high-traffic areas. Evaluating quartz porosity ensures you select a material that balances aesthetic appeal with functionality and longevity.

Porosity vs Non-Porosity Infographic

materialdif.com

materialdif.com