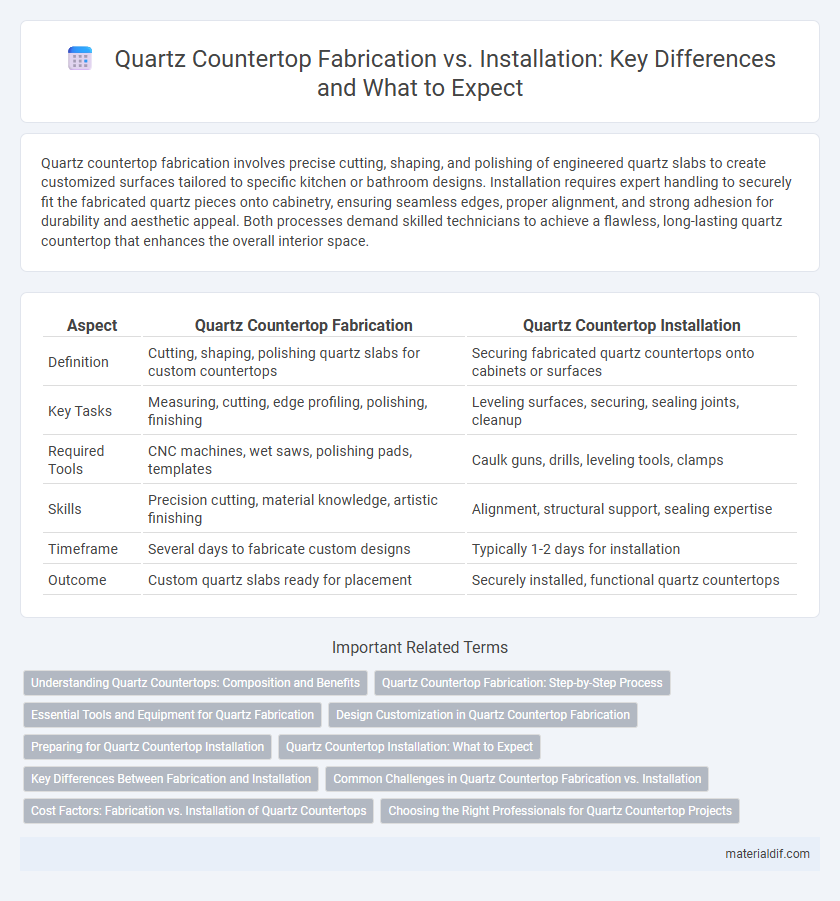

Quartz countertop fabrication involves precise cutting, shaping, and polishing of engineered quartz slabs to create customized surfaces tailored to specific kitchen or bathroom designs. Installation requires expert handling to securely fit the fabricated quartz pieces onto cabinetry, ensuring seamless edges, proper alignment, and strong adhesion for durability and aesthetic appeal. Both processes demand skilled technicians to achieve a flawless, long-lasting quartz countertop that enhances the overall interior space.

Table of Comparison

| Aspect | Quartz Countertop Fabrication | Quartz Countertop Installation |

|---|---|---|

| Definition | Cutting, shaping, polishing quartz slabs for custom countertops | Securing fabricated quartz countertops onto cabinets or surfaces |

| Key Tasks | Measuring, cutting, edge profiling, polishing, finishing | Leveling surfaces, securing, sealing joints, cleanup |

| Required Tools | CNC machines, wet saws, polishing pads, templates | Caulk guns, drills, leveling tools, clamps |

| Skills | Precision cutting, material knowledge, artistic finishing | Alignment, structural support, sealing expertise |

| Timeframe | Several days to fabricate custom designs | Typically 1-2 days for installation |

| Outcome | Custom quartz slabs ready for placement | Securely installed, functional quartz countertops |

Understanding Quartz Countertops: Composition and Benefits

Quartz countertops combine approximately 90-95% natural quartz crystals with resins and pigments, creating a durable and non-porous surface ideal for kitchen and bathroom applications. Their engineered composition ensures high resistance to scratches, stains, and heat, while offering a consistent appearance and a wide range of color options. Understanding these benefits highlights why quartz countertops are a preferred choice for both fabrication precision and seamless installation in modern interiors.

Quartz Countertop Fabrication: Step-by-Step Process

Quartz countertop fabrication begins with selecting high-quality quartz slabs that offer durability and aesthetic appeal. Precise cutting and shaping using advanced CNC machines ensure custom dimensions and unique design features are achieved. Final steps include polishing, edge profiling, and quality inspection to prepare the quartz surface for seamless installation.

Essential Tools and Equipment for Quartz Fabrication

Quartz countertop fabrication demands precise tools such as bridge saws, CNC routers, and polished diamond blades to shape and smooth the slabs accurately. Essential equipment also includes wet cutting tables to minimize dust and ensure clean cuts, along with pneumatic polishers to achieve a flawless surface finish. Proper use of these specialized tools directly impacts the quality and durability of the final quartz countertop installation.

Design Customization in Quartz Countertop Fabrication

Quartz countertop fabrication offers unparalleled design customization, allowing precise cutting, shaping, and edge detailing tailored to unique kitchen layouts and styles. Advanced fabrication techniques enable incorporation of intricate patterns, integrated sinks, and seamless joins that standard installation cannot achieve. This customization ensures a perfect fit and personalized aesthetic, enhancing both functionality and visual appeal in quartz countertops.

Preparing for Quartz Countertop Installation

Preparing for quartz countertop installation involves precise measurement and ensuring the cabinetry is level and secure to support the heavy quartz slabs. Protecting existing surfaces and clearing the workspace minimize damage and allow installers to work efficiently. Proper site preparation reduces installation errors, ensuring a seamless fit and long-lasting durability for the quartz countertops.

Quartz Countertop Installation: What to Expect

Quartz countertop installation involves precise measurements and careful handling to avoid damage to the engineered stone. Expect professional installers to use specialized adhesives and securing techniques to ensure durability and a seamless fit with surrounding cabinetry and fixtures. Proper installation also includes thorough surface leveling, edge finishing, and inspection to guarantee a polished, long-lasting result.

Key Differences Between Fabrication and Installation

Quartz countertop fabrication involves cutting, shaping, and polishing engineered quartz slabs to precise dimensions and design specifications, ensuring custom fit and finish. Installation refers to the process of transporting the fabricated quartz slabs to the site, securing them onto cabinets or surfaces, and sealing joints for stability and durability. Key differences include fabrication being a controlled workshop process centered on material preparation, while installation requires on-site precision and handling to integrate the countertop into the overall kitchen or bathroom layout.

Common Challenges in Quartz Countertop Fabrication vs. Installation

Quartz countertop fabrication often faces challenges such as precise cutting, edge profiling, and ensuring seamless joints, which require specialized tools and skilled craftsmanship. Installation challenges include aligning slabs accurately, handling heavy materials without damage, and fitting countertops to irregular or uneven surfaces. Both stages demand meticulous attention to measurements and quality control to prevent costly mistakes and maintain the durability of quartz surfaces.

Cost Factors: Fabrication vs. Installation of Quartz Countertops

Quartz countertop fabrication costs are influenced by material quality, slab size, and customization such as edge profiles and cutouts, typically ranging from $40 to $100 per square foot. Installation costs vary based on labor complexity, countertop weight, site preparation, and geographically variable contractor rates, generally averaging $35 to $70 per square foot. Understanding these distinct cost factors helps optimize budgeting, balancing high-quality fabrication with efficient installation for quartz countertops.

Choosing the Right Professionals for Quartz Countertop Projects

Selecting experienced professionals for quartz countertop fabrication and installation ensures precision in cutting, edge profiling, and fitting, minimizing material waste and enhancing durability. Certified fabricators utilize advanced CNC machinery and adhere to manufacturer guidelines, guaranteeing seamless seams and proper support to prevent cracking or damage. Trusting specialists with comprehensive knowledge of quartz properties leads to a flawless finish and long-lasting surface performance in kitchen or bathroom renovations.

Quartz Countertop Fabrication vs Installation Infographic

materialdif.com

materialdif.com