UV quartz offers superior clarity and durability compared to non-UV quartz, making it ideal for applications requiring high UV resistance such as in optical instruments and solar panels. Non-UV quartz lacks this enhanced protection, resulting in faster degradation and reduced performance when exposed to ultraviolet light. Choosing UV quartz ensures longer-lasting materials capable of withstanding harsh environmental conditions without losing their structural integrity.

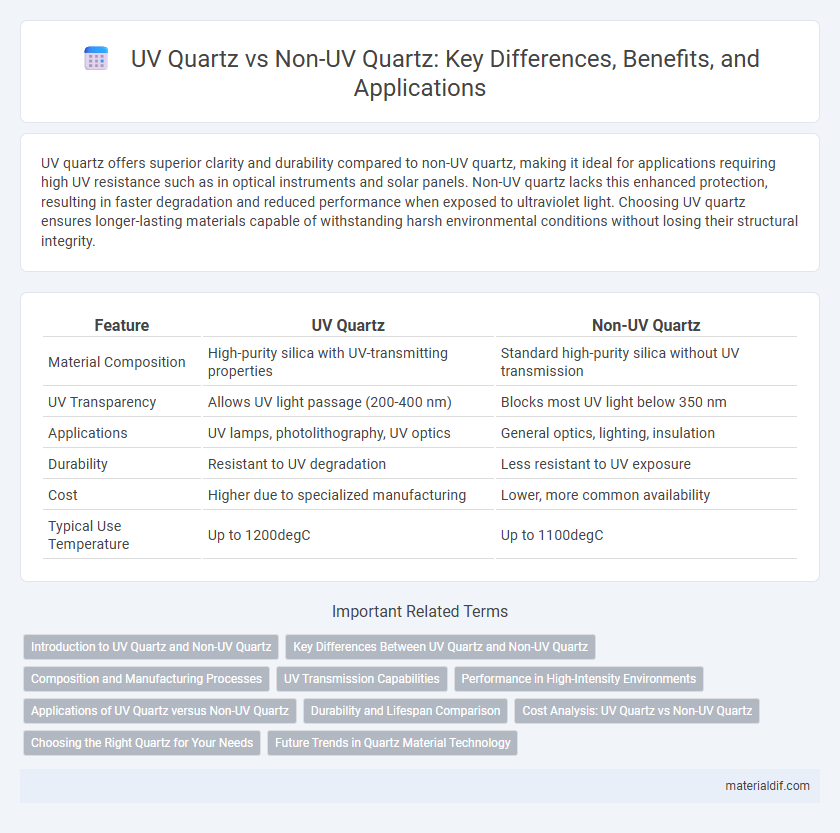

Table of Comparison

| Feature | UV Quartz | Non-UV Quartz |

|---|---|---|

| Material Composition | High-purity silica with UV-transmitting properties | Standard high-purity silica without UV transmission |

| UV Transparency | Allows UV light passage (200-400 nm) | Blocks most UV light below 350 nm |

| Applications | UV lamps, photolithography, UV optics | General optics, lighting, insulation |

| Durability | Resistant to UV degradation | Less resistant to UV exposure |

| Cost | Higher due to specialized manufacturing | Lower, more common availability |

| Typical Use Temperature | Up to 1200degC | Up to 1100degC |

Introduction to UV Quartz and Non-UV Quartz

UV quartz is specially formulated to transmit ultraviolet light with high clarity, making it ideal for applications like UV spectroscopy and photolithography. Non-UV quartz, often known as standard or fused silica quartz, primarily transmits visible and infrared light but blocks most UV radiation. The distinction between UV quartz and non-UV quartz lies in their purity and transmission properties, which directly impact their effectiveness in optical and industrial uses.

Key Differences Between UV Quartz and Non-UV Quartz

UV quartz contains unique properties that enable it to absorb and filter ultraviolet light, making it essential in applications like UV lamps and sterilization equipment. Non-UV quartz lacks this UV-absorbing capability but excels in general optical clarity and thermal resistance, suitable for standard glassware and lenses. The key difference lies in their performance under UV exposure, with UV quartz designed for UV light transmission and non-UV quartz optimized for broader spectral transparency.

Composition and Manufacturing Processes

UV quartz is composed primarily of high-purity silicon dioxide and undergoes a special manufacturing process involving controlled UV exposure to enhance its transmissivity and durability for ultraviolet light applications. Non-UV quartz, while also based on silicon dioxide, is produced through traditional melting and cooling methods without UV-specific treatments, resulting in different optical and physical properties. The manufacturing distinction significantly affects the composition, with UV quartz often exhibiting fewer impurities and a structure optimized for UV light passage.

UV Transmission Capabilities

UV quartz, also known as fused silica, exhibits superior UV transmission capabilities, allowing wavelengths as short as 190 nm to pass through with minimal attenuation. Non-UV quartz materials typically block or absorb UV light below 250 nm, limiting their efficiency in applications like photolithography, UV spectroscopy, and UV curing. The high UV transparency of UV quartz makes it ideal for precise optical components, ensuring maximum performance in ultraviolet light environments.

Performance in High-Intensity Environments

UV quartz exhibits superior performance in high-intensity environments due to its enhanced resistance to ultraviolet radiation and thermal stress, maintaining structural integrity and clarity under prolonged exposure. Non-UV quartz, while durable, tends to degrade faster when subjected to intense UV light and elevated temperatures, leading to potential translucency loss and reduced lifespan. These characteristics make UV quartz the preferred choice for applications demanding consistent optical properties and durability under harsh conditions.

Applications of UV Quartz versus Non-UV Quartz

UV quartz exhibits exceptional transparency to ultraviolet light, making it ideal for applications in UV sterilization, photolithography, and UV curing processes. Non-UV quartz, with limited UV transmission but strong resistance to thermal shock and chemical corrosion, is typically used in industrial furnaces, high-temperature lamps, and optical components where UV exposure is minimal. The selection between UV and non-UV quartz depends primarily on the required optical properties and environmental conditions of the application.

Durability and Lifespan Comparison

UV quartz exhibits higher durability compared to non-UV quartz due to its enhanced resistance to thermal shock and chemical exposure. The ultraviolet treatment strengthens the molecular structure, resulting in a significantly longer lifespan under harsh environmental conditions. Non-UV quartz, while still durable, tends to degrade faster when exposed to intense heat and sunlight, reducing its effective service life.

Cost Analysis: UV Quartz vs Non-UV Quartz

UV quartz generally incurs higher production costs due to the specialized raw materials and manufacturing processes required to enhance ultraviolet light transmission. Non-UV quartz is more cost-effective, benefiting from standard fabrication techniques and widely available materials, resulting in lower market prices. When analyzing total expenses, UV quartz offers superior performance in UV-sensitive applications but at a premium, whereas non-UV quartz provides budget-friendly suitability for general use.

Choosing the Right Quartz for Your Needs

UV quartz offers superior clarity and enhanced resistance to sunlight degradation, making it ideal for applications requiring high UV transmission and durability. Non-UV quartz is more cost-effective and suitable for general-purpose uses where UV exposure is minimal or not a concern. Selecting the right quartz depends on the specific application's exposure to UV light, budget constraints, and performance requirements.

Future Trends in Quartz Material Technology

Future trends in quartz material technology highlight the growing adoption of UV quartz due to its superior durability and enhanced light transmission properties compared to non-UV quartz. Innovations in UV quartz manufacturing techniques are driving improvements in precision optics, semiconductor photolithography, and advanced UV sterilization applications. Continued research focuses on maximizing UV quartz's resistance to thermal shock and chemical corrosion, positioning it as the preferred material for next-generation high-performance UV equipment.

UV Quartz vs Non-UV Quartz Infographic

materialdif.com

materialdif.com