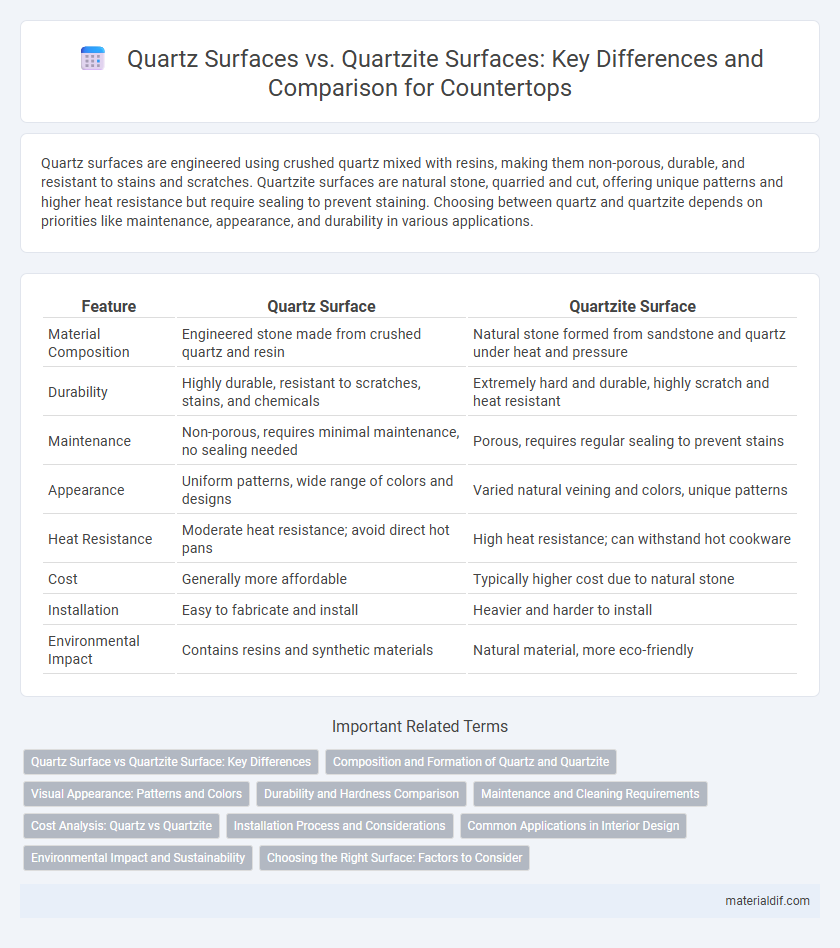

Quartz surfaces are engineered using crushed quartz mixed with resins, making them non-porous, durable, and resistant to stains and scratches. Quartzite surfaces are natural stone, quarried and cut, offering unique patterns and higher heat resistance but require sealing to prevent staining. Choosing between quartz and quartzite depends on priorities like maintenance, appearance, and durability in various applications.

Table of Comparison

| Feature | Quartz Surface | Quartzite Surface |

|---|---|---|

| Material Composition | Engineered stone made from crushed quartz and resin | Natural stone formed from sandstone and quartz under heat and pressure |

| Durability | Highly durable, resistant to scratches, stains, and chemicals | Extremely hard and durable, highly scratch and heat resistant |

| Maintenance | Non-porous, requires minimal maintenance, no sealing needed | Porous, requires regular sealing to prevent stains |

| Appearance | Uniform patterns, wide range of colors and designs | Varied natural veining and colors, unique patterns |

| Heat Resistance | Moderate heat resistance; avoid direct hot pans | High heat resistance; can withstand hot cookware |

| Cost | Generally more affordable | Typically higher cost due to natural stone |

| Installation | Easy to fabricate and install | Heavier and harder to install |

| Environmental Impact | Contains resins and synthetic materials | Natural material, more eco-friendly |

Quartz Surface vs Quartzite Surface: Key Differences

Quartz surfaces are engineered materials composed of about 90% crushed quartz mixed with resin and pigments, offering consistent patterns and colors, high durability, and non-porous properties that resist stains and scratches. Quartzite surfaces are natural stone formed from sandstone transformed by heat and pressure, characterized by unique veining and variations, excellent heat resistance, and stronger scratch resistance but require sealing to prevent staining. Key differences include quartz's uniform appearance and maintenance ease versus quartzite's natural, varied aesthetics and need for periodic sealing to maintain its surface integrity.

Composition and Formation of Quartz and Quartzite

Quartz surfaces are engineered from crushed natural quartz crystals combined with resins and pigments, resulting in a durable, non-porous material ideal for countertops. Quartzite surfaces originate from natural quartz-rich sandstone subjected to intense heat and pressure over millions of years, transforming the quartz grains into a hard, metamorphic rock with a natural, unique pattern. The key difference lies in quartz being a manufactured product with consistent composition, while quartzite is a naturally occurring stone with variable mineral content and formation history.

Visual Appearance: Patterns and Colors

Quartz surfaces offer a wide range of consistent patterns and vibrant colors due to engineered blending of natural quartz and pigments, allowing for uniform appearance and customization. Quartzite surfaces, being natural stone, display unique, unpredictable veining and a more organic palette with varied hues ranging from white and gray to pink and green. The distinct visual characteristics of quartzite provide a one-of-a-kind, natural look, whereas quartz offers more predictable patterns suitable for cohesive design themes.

Durability and Hardness Comparison

Quartz surfaces, engineered from natural quartz crystals combined with resin, exhibit high durability and resistance to scratches and stains, making them ideal for kitchen countertops. Quartzite, a natural stone formed from sandstone, ranks higher on the Mohs hardness scale, offering superior scratch resistance and heat durability compared to quartz surfaces. Both materials provide excellent durability, but quartzite's natural hardness makes it better suited for heavy-duty applications requiring enhanced toughness.

Maintenance and Cleaning Requirements

Quartz surfaces require low maintenance with non-porous properties that resist staining and eliminate the need for sealing; everyday cleaning involves mild soap and water or a gentle household cleaner. Quartzite surfaces, being natural stone, need periodic sealing to prevent staining and require careful cleaning with pH-balanced stone cleaners to avoid damage. Both surfaces benefit from avoiding harsh chemicals and abrasive materials to maintain their aesthetic and durability.

Cost Analysis: Quartz vs Quartzite

Quartz surfaces typically cost between $50 to $150 per square foot, offering a more budget-friendly option compared to quartzite, which ranges from $70 to $200 per square foot due to its natural stone composition and limited supply. Installation expenses for quartzite can also be higher because of its hardness, requiring specialized tools and labor, whereas quartz's engineered nature allows for easier and less costly fabrication. Long-term maintenance costs favor quartz, as quartzite may need regular sealing and more careful upkeep to prevent staining and etching.

Installation Process and Considerations

Quartz surfaces offer a straightforward installation process since they are engineered materials composed of natural quartz particles mixed with resins, allowing for precise cutting and minimal sealing requirements. Quartzite surfaces require more meticulous handling due to their natural stone composition, necessitating heavier tools for cutting and consistent sealing to prevent staining and damage. Installation of quartz typically involves adhesive bonding to substrates, while quartzite demands anchoring techniques that accommodate its natural variability and weight.

Common Applications in Interior Design

Quartz surfaces are popular in kitchen countertops, bathroom vanities, and backsplashes due to their non-porous nature and wide range of colors and patterns. Quartzite surfaces, often chosen for flooring, wall cladding, and fireplace surrounds, provide natural stone aesthetics with higher heat resistance and durability. Both materials enhance interior design by balancing functionality and style, with quartz favored for consistent finishes and quartzite for unique, natural veining.

Environmental Impact and Sustainability

Quartz surfaces, engineered from crushed quartz and resins, have a lower environmental impact due to controlled manufacturing processes that reduce waste and energy consumption. Quartzite, a natural stone, involves quarrying that disrupts ecosystems and requires significant energy for extraction and transportation. Sustainability favors quartz surfaces with their recyclable components and reduced ecological footprint compared to the more resource-intensive extraction and processing of quartzite.

Choosing the Right Surface: Factors to Consider

Quartz surfaces offer non-porous, low-maintenance durability ideal for kitchens and bathrooms, resisting stains and scratches better than natural stone alternatives. Quartzite surfaces provide natural stone aesthetics with higher heat resistance and unique veining patterns, but require sealing to prevent staining and etching. Choosing the right surface depends on factors such as maintenance preferences, durability needs, heat resistance, and the desired aesthetic appeal.

Quartz Surface vs Quartzite Surface Infographic

materialdif.com

materialdif.com