Crushed quartz consists of naturally occurring quartz that has been mechanically broken into small pieces, retaining its crystalline structure and often used in construction and decorative applications. Fused quartz is produced by melting high-purity quartz crystals at extremely high temperatures, resulting in a non-crystalline, glassy material with superior thermal and chemical stability. The choice between crushed and fused quartz depends on application needs, with crushed quartz favored for abrasive and filtration uses, while fused quartz is ideal for high-temperature environments and optical components.

Table of Comparison

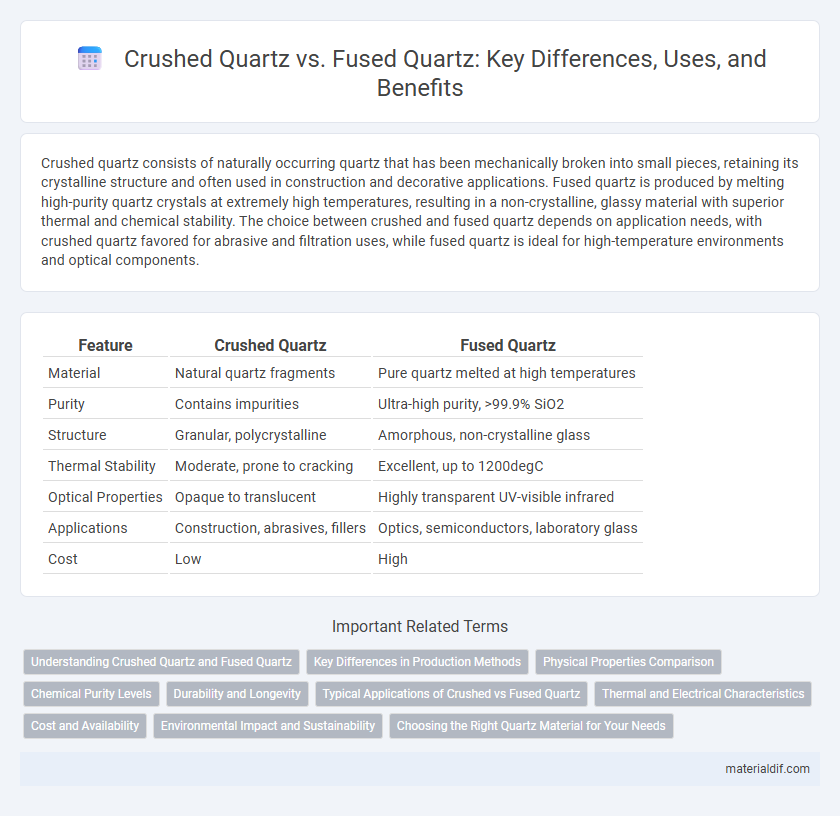

| Feature | Crushed Quartz | Fused Quartz |

|---|---|---|

| Material | Natural quartz fragments | Pure quartz melted at high temperatures |

| Purity | Contains impurities | Ultra-high purity, >99.9% SiO2 |

| Structure | Granular, polycrystalline | Amorphous, non-crystalline glass |

| Thermal Stability | Moderate, prone to cracking | Excellent, up to 1200degC |

| Optical Properties | Opaque to translucent | Highly transparent UV-visible infrared |

| Applications | Construction, abrasives, fillers | Optics, semiconductors, laboratory glass |

| Cost | Low | High |

Understanding Crushed Quartz and Fused Quartz

Crushed quartz consists of mechanically broken quartz particles typically used in construction and industrial applications, offering high hardness and chemical inertness. Fused quartz is produced by melting natural quartz at extremely high temperatures, resulting in a glass-like material with superior thermal stability, low thermal expansion, and excellent optical clarity. Understanding the differences in structure and manufacturing processes between crushed quartz and fused quartz is essential for selecting the appropriate quartz form in scientific, industrial, and technological uses.

Key Differences in Production Methods

Crushed quartz is produced by mechanically grinding natural quartz crystals into fine particles, retaining the material's original crystalline structure. Fused quartz is manufactured through the melting of high-purity quartz sand at extremely high temperatures, resulting in a non-crystalline, amorphous glass. The production process of crushed quartz involves physical transformation, while fused quartz undergoes a thermal phase change, leading to different physical and chemical properties.

Physical Properties Comparison

Crushed quartz exhibits irregular, angular grains with varying particle sizes and higher surface area, leading to increased porosity and reduced density compared to fused quartz. Fused quartz is formed by melting high-purity quartz sand, resulting in a homogeneous, non-porous, and highly dense glass-like structure with superior mechanical strength and thermal shock resistance. The distinct physical properties impact their applications, where crushed quartz is preferred in abrasives and fillers, while fused quartz is essential for optical components and high-temperature environments.

Chemical Purity Levels

Crushed quartz typically contains higher levels of impurities such as iron, aluminum, and titanium oxides, impacting its chemical purity and suitability for high-precision applications. Fused quartz is produced by melting high-purity quartz crystals at extremely high temperatures, resulting in a material with chemical purity exceeding 99.99%, essential for semiconductor manufacturing and optical devices. The superior purity of fused quartz minimizes trace contaminants, providing enhanced thermal stability and optical clarity compared to crushed quartz.

Durability and Longevity

Crushed quartz, composed of fragmented natural quartz crystals, tends to have lower durability due to its irregular surfaces and micro-cracks, making it more susceptible to wear and breakage under stress. Fused quartz, produced by melting natural quartz to form a homogeneous, non-crystalline glass, offers superior durability and longevity due to its high purity, resistance to thermal shock, and structural integrity. This enhanced durability makes fused quartz ideal for high-performance applications such as optics, semiconductors, and laboratory equipment where long-term reliability is critical.

Typical Applications of Crushed vs Fused Quartz

Crushed quartz is commonly used in construction materials, ceramics, and as an abrasive due to its granular texture and high hardness, ensuring durability in concrete, sandblasting, and grinding applications. Fused quartz, known for its exceptional thermal resistance and optical clarity, is typically utilized in high-tech applications such as semiconductor manufacturing, fiber optics, and precision lenses. The distinct structural properties of crushed quartz and fused quartz dictate their specialized uses, with crushed quartz favored in mechanical processes and fused quartz in environments requiring thermal stability and purity.

Thermal and Electrical Characteristics

Crushed quartz exhibits high thermal stability with excellent resistance to thermal shock, making it ideal for refractory applications, while fused quartz offers superior thermal conductivity and minimal thermal expansion for precision optical and semiconductor uses. Electrically, fused quartz boasts exceptional insulating properties and extremely low dielectric constant, outperforming crushed quartz in high-frequency and high-voltage environments. The amorphous structure of fused quartz ensures uniform electrical behavior, whereas crushed quartz's crystalline nature results in varied conductivity and dielectric performance.

Cost and Availability

Crushed quartz is generally more affordable and widely available due to its natural extraction and minimal processing requirements, making it a cost-effective choice for construction and industrial uses. Fused quartz, produced by melting high-purity quartz crystals at extreme temperatures, commands a higher price because of its superior thermal and chemical stability, as well as its specialized manufacturing process. Availability of fused quartz is more limited, often restricted to suppliers serving high-tech industries such as optics and semiconductor manufacturing.

Environmental Impact and Sustainability

Crushed quartz, derived from natural quartz deposits, involves mining processes that can lead to habitat disruption, energy-intensive extraction, and significant waste generation, raising environmental concerns. Fused quartz, produced by melting high-purity quartz sand at extremely high temperatures, offers enhanced purity and durability, enabling longer lifespan materials with less frequent replacement and reduced resource consumption. Sustainable choices favor fused quartz for its recyclability and lower ecological footprint over time despite higher initial energy input during manufacturing.

Choosing the Right Quartz Material for Your Needs

Crushed quartz offers high surface area and is ideal for applications requiring abrasiveness or enhanced reactivity, such as in coatings or abrasives. Fused quartz provides superior thermal stability, low thermal expansion, and excellent optical clarity, making it suitable for high-temperature industrial processes and precision optics. Selecting the right quartz material depends on specific performance criteria like mechanical strength, thermal resistance, and purity requirements.

Crushed Quartz vs Fused Quartz Infographic

materialdif.com

materialdif.com