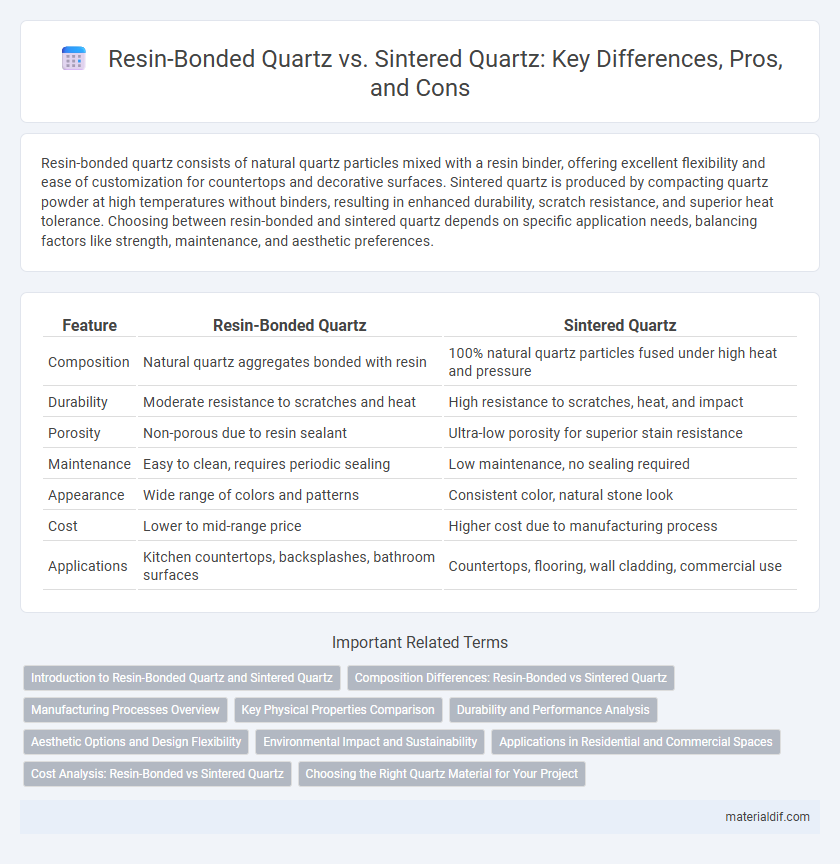

Resin-bonded quartz consists of natural quartz particles mixed with a resin binder, offering excellent flexibility and ease of customization for countertops and decorative surfaces. Sintered quartz is produced by compacting quartz powder at high temperatures without binders, resulting in enhanced durability, scratch resistance, and superior heat tolerance. Choosing between resin-bonded and sintered quartz depends on specific application needs, balancing factors like strength, maintenance, and aesthetic preferences.

Table of Comparison

| Feature | Resin-Bonded Quartz | Sintered Quartz |

|---|---|---|

| Composition | Natural quartz aggregates bonded with resin | 100% natural quartz particles fused under high heat and pressure |

| Durability | Moderate resistance to scratches and heat | High resistance to scratches, heat, and impact |

| Porosity | Non-porous due to resin sealant | Ultra-low porosity for superior stain resistance |

| Maintenance | Easy to clean, requires periodic sealing | Low maintenance, no sealing required |

| Appearance | Wide range of colors and patterns | Consistent color, natural stone look |

| Cost | Lower to mid-range price | Higher cost due to manufacturing process |

| Applications | Kitchen countertops, backsplashes, bathroom surfaces | Countertops, flooring, wall cladding, commercial use |

Introduction to Resin-Bonded Quartz and Sintered Quartz

Resin-bonded quartz is engineered by combining natural quartz crystals with a polymer resin, creating a durable, non-porous surface prized for its stain resistance and ease of maintenance. Sintered quartz is produced through a high-temperature, high-pressure process that fuses quartz particles into a solid slab without resins, offering enhanced heat resistance and chemical stability for demanding applications. Both materials provide distinct advantages in kitchen countertops, with resin-bonded quartz emphasizing aesthetic versatility and sintered quartz delivering superior durability.

Composition Differences: Resin-Bonded vs Sintered Quartz

Resin-bonded quartz consists of approximately 90-95% natural quartz crystals combined with a polymer resin binder, offering enhanced flexibility and ease of fabrication. In contrast, sintered quartz is manufactured by compressing and heating pure quartz particles at extremely high temperatures without any resin, resulting in a highly durable, non-porous surface with superior heat and scratch resistance. The fundamental composition difference impacts performance, maintenance, and application suitability between resin-bonded and sintered quartz materials.

Manufacturing Processes Overview

Resin-bonded quartz is manufactured by mixing quartz aggregates with a resin binder, then curing the mixture under controlled heat and pressure to create a durable, non-porous surface. Sintered quartz involves compressing finely ground quartz powder at extremely high temperatures without using adhesives, resulting in a dense, highly durable slab with enhanced resistance to heat and scratches. The distinct manufacturing processes influence the material properties, with resin-bonded quartz offering more flexibility and color variety, while sintered quartz provides superior hardness and thermal stability.

Key Physical Properties Comparison

Resin-bonded quartz features enhanced flexibility and impact resistance due to its polymer matrix, making it ideal for applications requiring slight elasticity. Sintered quartz offers superior hardness, thermal stability, and chemical resistance, attributed to its fused crystalline structure formed under high temperature and pressure. The comparison highlights resin-bonded quartz's abrasion resistance up to 25 MPa versus sintered quartz's superior hardness exceeding 9 Mohs and thermal resistance above 1000degC.

Durability and Performance Analysis

Resin-bonded quartz surfaces combine crushed quartz with resin polymers, offering moderate durability and resistance to stains but are more prone to scratches and heat damage compared to sintered quartz. Sintered quartz, made through a high-temperature fusion of natural minerals, provides superior hardness, enhanced resistance to abrasion, heat, and chemicals, outperforming resin-bonded quartz in long-term durability and surface integrity. This performance analysis highlights sintered quartz as the preferred choice for high-traffic or industrial environments demanding exceptional strength and longevity.

Aesthetic Options and Design Flexibility

Resin-bonded quartz offers a wider range of aesthetic options with its vibrant colors and intricate patterns achievable through resin infusion, enhancing design flexibility for custom applications. Sintered quartz provides a more uniform and natural stone appearance with high durability, suited for minimalist and modern designs where texture and subtle color variations are valued. Both materials support versatile design projects, but resin-bonded quartz excels in creative expression while sintered quartz emphasizes structural consistency and natural aesthetics.

Environmental Impact and Sustainability

Resin-bonded quartz surfaces typically involve synthetic resins that can release volatile organic compounds (VOCs) during production and disposal, raising environmental concerns. In contrast, sintered quartz is created through high-pressure and high-temperature processes that use natural minerals with fewer chemical additives, resulting in a more eco-friendly lifecycle and higher recyclability. The sustainability of sintered quartz is enhanced by its durability and lower reliance on petrochemical-based materials, making it a preferable option for environmentally conscious construction and design projects.

Applications in Residential and Commercial Spaces

Resin-bonded quartz surfaces, known for their high durability and ease of maintenance, are ideal for residential kitchens and bathrooms where stain resistance and aesthetic versatility are essential. Sintered quartz, offering superior heat resistance and scratch hardness, suits commercial environments such as restaurant countertops and laboratory worktops requiring robust performance under heavy use. Both materials enhance interior design but are selected based on specific functional demands in residential or commercial applications.

Cost Analysis: Resin-Bonded vs Sintered Quartz

Resin-bonded quartz typically offers a lower cost due to less intensive manufacturing processes and reduced energy consumption compared to sintered quartz. Sintered quartz, however, provides greater durability and heat resistance, which can justify the higher initial investment for long-term applications. Selecting between resin-bonded and sintered quartz depends on balancing upfront material expenses with expected lifespan and performance requirements.

Choosing the Right Quartz Material for Your Project

Resin-bonded quartz offers enhanced flexibility and ease of installation, making it ideal for residential countertops and decorative surfaces where customization is key. Sintered quartz, produced through advanced compression and high-temperature bonding, provides superior durability and heat resistance, perfectly suited for commercial environments and heavy-use applications. Selecting the right quartz material depends on project requirements such as durability, aesthetic preferences, and budget, ensuring performance aligns with functional needs.

Resin-Bonded Quartz vs Sintered Quartz Infographic

materialdif.com

materialdif.com