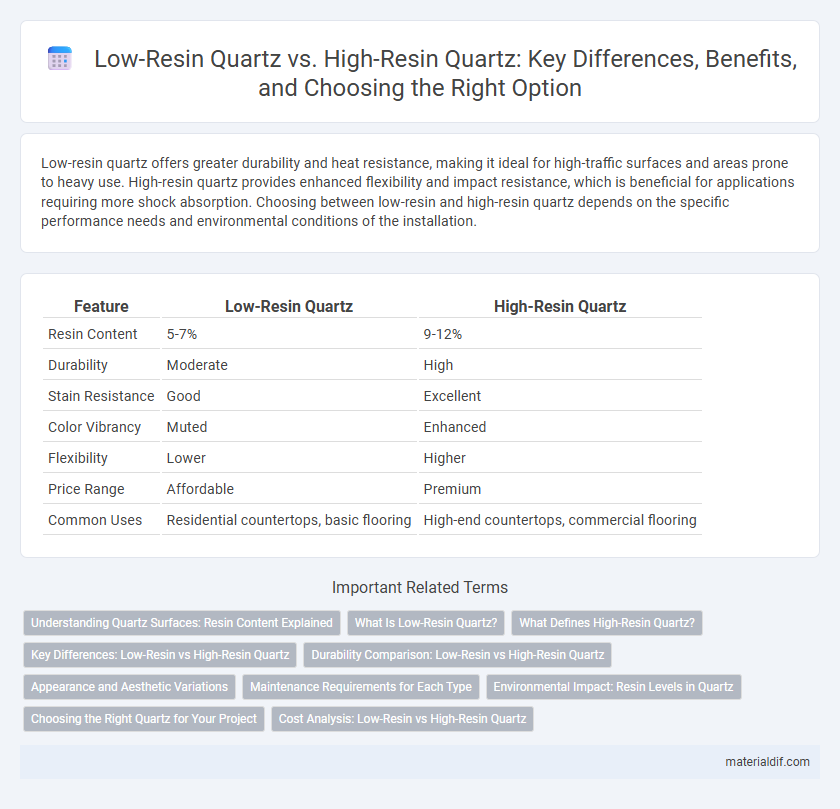

Low-resin quartz offers greater durability and heat resistance, making it ideal for high-traffic surfaces and areas prone to heavy use. High-resin quartz provides enhanced flexibility and impact resistance, which is beneficial for applications requiring more shock absorption. Choosing between low-resin and high-resin quartz depends on the specific performance needs and environmental conditions of the installation.

Table of Comparison

| Feature | Low-Resin Quartz | High-Resin Quartz |

|---|---|---|

| Resin Content | 5-7% | 9-12% |

| Durability | Moderate | High |

| Stain Resistance | Good | Excellent |

| Color Vibrancy | Muted | Enhanced |

| Flexibility | Lower | Higher |

| Price Range | Affordable | Premium |

| Common Uses | Residential countertops, basic flooring | High-end countertops, commercial flooring |

Understanding Quartz Surfaces: Resin Content Explained

Low-resin quartz surfaces contain a minimal amount of resin, resulting in enhanced natural stone aesthetics but lower stain resistance and durability compared to high-resin quartz. High-resin quartz incorporates a greater concentration of resin, improving resilience against impacts, scratches, and stains while slightly reducing the natural stone appearance. Understanding quartz resin content helps in choosing the right surface for specific applications, balancing beauty with functional performance.

What Is Low-Resin Quartz?

Low-resin quartz refers to engineered quartz surfaces containing a lower percentage of resin binders, typically below 7%, compared to high-resin quartz which can have resin content up to 10% or more. This composition results in a denser, more natural stone-like appearance with increased resistance to heat, scratches, and UV discoloration, making it ideal for both indoor and outdoor applications. Low-resin quartz slabs offer enhanced durability and typically require less maintenance due to reduced resin-related wear and fading over time.

What Defines High-Resin Quartz?

High-resin quartz is characterized by a higher percentage of polymer resin binder, typically exceeding 7%, which enhances its durability, stain resistance, and flexibility compared to low-resin quartz. This increased resin content contributes to a smoother, glossier surface finish and improved resistance to cracking under impact or thermal stress. Manufacturers often use high-resin quartz in premium applications where both aesthetic appeal and long-lasting performance are critical.

Key Differences: Low-Resin vs High-Resin Quartz

Low-resin quartz features a lower concentration of resin binders, resulting in a more natural stone appearance with higher porosity and increased susceptibility to staining. High-resin quartz incorporates more resin, enhancing durability, resistance to impact, and reducing porosity, making it ideal for high-traffic or moisture-prone environments. The key differences lie in performance characteristics where low-resin quartz offers better heat resistance but requires more maintenance, while high-resin quartz provides superior structural integrity and stain resistance.

Durability Comparison: Low-Resin vs High-Resin Quartz

Low-resin quartz typically features a higher content of natural quartz crystals, resulting in enhanced hardness and resistance to scratches compared to high-resin quartz, which contains more polymer binders that can reduce surface durability. High-resin quartz tends to be more flexible and impact-resistant, but its increased resin content can make it more prone to heat damage and discoloration over time. Overall, low-resin quartz offers superior durability for heavy-use applications, while high-resin quartz balances durability with improved workability and design versatility.

Appearance and Aesthetic Variations

Low-resin quartz showcases a more natural and translucent appearance, emphasizing the stone's inherent veining and color variations, ideal for designs seeking authenticity. High-resin quartz offers a polished, uniform finish with enhanced durability, creating sleek and vibrant surfaces that resist discoloration and maintain vivid hues. The choice between low-resin and high-resin quartz significantly impacts the visual texture and depth, influencing contemporary and classic interior aesthetics.

Maintenance Requirements for Each Type

Low-resin quartz typically demands less frequent maintenance due to its denser structure, which resists staining and scratching more effectively. High-resin quartz, while offering enhanced flexibility and vibrant color options, requires regular sealing and more careful cleaning to prevent damage from harsh chemicals and heat. Proper upkeep for both types ensures longevity, but low-resin quartz generally provides a more durable and easy-to-maintain surface ideal for high-traffic areas.

Environmental Impact: Resin Levels in Quartz

Low-resin quartz surfaces typically have a lower environmental impact because they require less synthetic resin, which is often derived from petroleum-based chemicals contributing to pollution and non-renewable resource depletion. High-resin quartz contains a greater proportion of resin binders, increasing its carbon footprint during production due to the energy-intensive processes involved in resin manufacturing and application. Choosing low-resin quartz supports more sustainable material use by minimizing reliance on synthetic polymers and reducing VOC emissions during installation and use.

Choosing the Right Quartz for Your Project

Low-resin quartz offers higher purity and better heat resistance, making it ideal for projects requiring durability and minimal discoloration. High-resin quartz provides enhanced flexibility and impact resistance, suitable for applications involving frequent handling or movement. Selecting the right quartz depends on balancing performance needs with environmental factors and aesthetic preferences to ensure optimal functionality and longevity.

Cost Analysis: Low-Resin vs High-Resin Quartz

Low-resin quartz generally costs less due to its simpler manufacturing process and lower material content, making it a budget-friendly option for large-scale applications. High-resin quartz features increased resin content, which enhances durability and stain resistance but raises production expenses, resulting in a higher price point. When comparing investment value, low-resin quartz suits cost-sensitive projects, while high-resin quartz justifies its premium cost through enhanced performance and longevity.

Low-Resin Quartz vs High-Resin Quartz Infographic

materialdif.com

materialdif.com