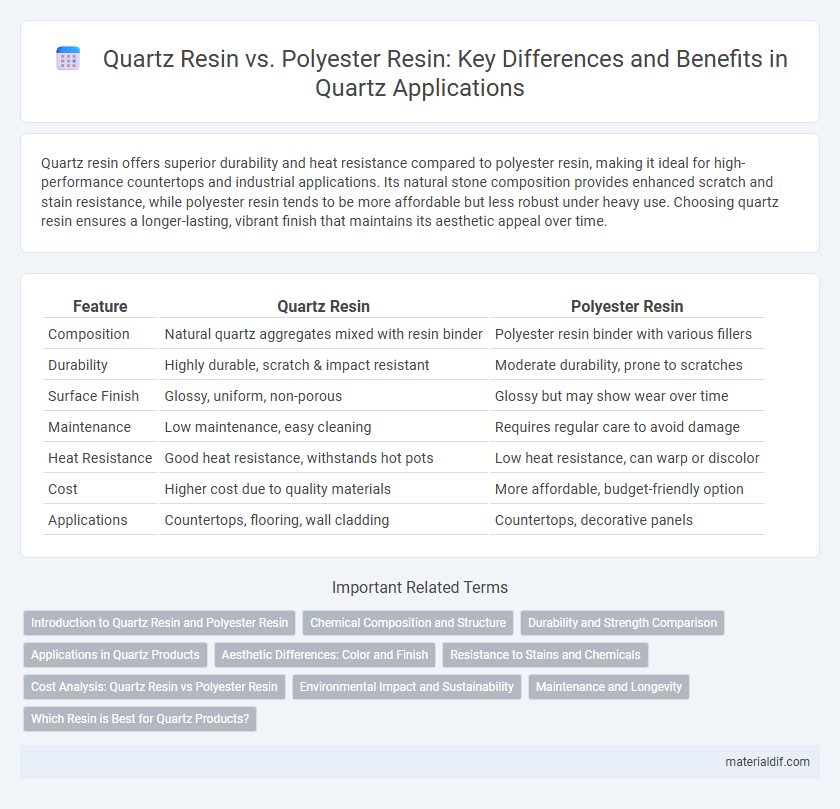

Quartz resin offers superior durability and heat resistance compared to polyester resin, making it ideal for high-performance countertops and industrial applications. Its natural stone composition provides enhanced scratch and stain resistance, while polyester resin tends to be more affordable but less robust under heavy use. Choosing quartz resin ensures a longer-lasting, vibrant finish that maintains its aesthetic appeal over time.

Table of Comparison

| Feature | Quartz Resin | Polyester Resin |

|---|---|---|

| Composition | Natural quartz aggregates mixed with resin binder | Polyester resin binder with various fillers |

| Durability | Highly durable, scratch & impact resistant | Moderate durability, prone to scratches |

| Surface Finish | Glossy, uniform, non-porous | Glossy but may show wear over time |

| Maintenance | Low maintenance, easy cleaning | Requires regular care to avoid damage |

| Heat Resistance | Good heat resistance, withstands hot pots | Low heat resistance, can warp or discolor |

| Cost | Higher cost due to quality materials | More affordable, budget-friendly option |

| Applications | Countertops, flooring, wall cladding | Countertops, decorative panels |

Introduction to Quartz Resin and Polyester Resin

Quartz resin, a composite material combining natural quartz with resin binders, offers exceptional durability and heat resistance, making it ideal for kitchen countertops and industrial applications. Polyester resin, a synthetic polymer known for its versatility and affordability, is frequently used in fiberglass laminates and casting due to its strong adhesion and chemical resistance. Both resins serve different purposes, with quartz resin excelling in structural integrity and aesthetics, while polyester resin provides cost-effective solutions in manufacturing and prototyping.

Chemical Composition and Structure

Quartz resin typically features a siloxane-based chemical composition incorporating silicon dioxide (SiO2) particles, providing enhanced thermal stability and mechanical strength. Polyester resin consists mainly of unsaturated polyester chains derived from dibasic organic acids and glycols, creating a cross-linked polymer network upon curing. The inorganic quartz particles in quartz resin contribute to superior hardness and chemical resistance compared to the organic matrix of polyester resin.

Durability and Strength Comparison

Quartz resin exhibits superior durability and strength compared to polyester resin, making it ideal for high-traffic surfaces and industrial applications. The quartz particles within the resin matrix enhance resistance to scratches, heat, and impact, resulting in a longer lifespan and reduced maintenance requirements. Polyester resin, while cost-effective, tends to be less robust and more susceptible to wear and discoloration over time.

Applications in Quartz Products

Quartz resin primarily consists of natural quartz combined with a polymer binder, offering enhanced durability and heat resistance ideal for kitchen countertops and industrial surfaces. Polyester resin, a synthetic polymer, is commonly used in decorative quartz products due to its lower cost and ease of molding but is less resistant to heat and UV exposure. Applications demanding high mechanical strength and thermal stability favor quartz resin, while polyester resin suits decorative and budget-friendly quartz items.

Aesthetic Differences: Color and Finish

Quartz resin exhibits a natural, translucent appearance with subtle variations and a matte to satin finish that highlights the stone's natural beauty. Polyester resin offers vibrant color options and a high-gloss finish, creating a more uniform and polished look. The choice between quartz resin and polyester resin heavily influences the visual texture and overall aesthetic impact of surfaces like countertops and decorative elements.

Resistance to Stains and Chemicals

Quartz resin offers superior resistance to stains and chemicals compared to polyester resin, making it ideal for kitchen countertops and high-traffic surfaces. The non-porous surface of quartz resin prevents absorption of liquids and harsh chemicals, ensuring easier maintenance and durability over time. Polyester resin, while more affordable, is prone to discoloration and damage when exposed to acidic or abrasive substances, reducing its lifespan in demanding environments.

Cost Analysis: Quartz Resin vs Polyester Resin

Quartz resin generally incurs higher upfront costs compared to polyester resin due to superior material properties and enhanced durability, which reduce long-term maintenance expenses. Polyester resin is more budget-friendly initially but may require more frequent repairs or replacements, increasing total lifecycle costs. Investing in quartz resin offers better cost-efficiency over time, especially in high-traffic or industrial applications where wear resistance is critical.

Environmental Impact and Sustainability

Quartz resin exhibits a lower environmental impact compared to polyester resin due to its natural mineral composition and longer durability, reducing the frequency of replacement and waste generation. Polyester resin production involves petrochemicals and releases volatile organic compounds (VOCs), contributing to air pollution and resource depletion. Sustainable quartz resin options often incorporate recycled materials and improve energy efficiency during manufacturing, aligning better with eco-friendly building practices.

Maintenance and Longevity

Quartz resin offers superior durability and requires minimal maintenance compared to polyester resin, making it ideal for high-traffic surfaces. Its enhanced resistance to scratches, stains, and heat ensures prolonged aesthetic appeal and structural integrity over time. Polyester resin, while cost-effective, tends to yellow and degrade faster, demanding more frequent upkeep and eventual replacement.

Which Resin is Best for Quartz Products?

Quartz resin options include quartz resin and polyester resin, each offering distinct advantages for quartz products. Quartz resin typically provides superior durability, chemical resistance, and a more natural appearance, making it ideal for high-quality countertops and surfaces. Polyester resin is generally more cost-effective but may lack the long-term strength and aesthetic appeal of quartz resin, influencing its suitability depending on project requirements.

Quartz Resin vs Polyester Resin Infographic

materialdif.com

materialdif.com