Nano crystallized glass offers superior scratch resistance and enhanced clarity compared to traditional quartz, making it ideal for premium watch faces and electronic displays. While quartz boasts excellent durability and cost-effectiveness, nano crystallized glass achieves a higher level of hardness due to its advanced manufacturing process. This results in a sleek, more transparent material that maintains its aesthetic appeal over time, outperforming quartz in both functionality and design.

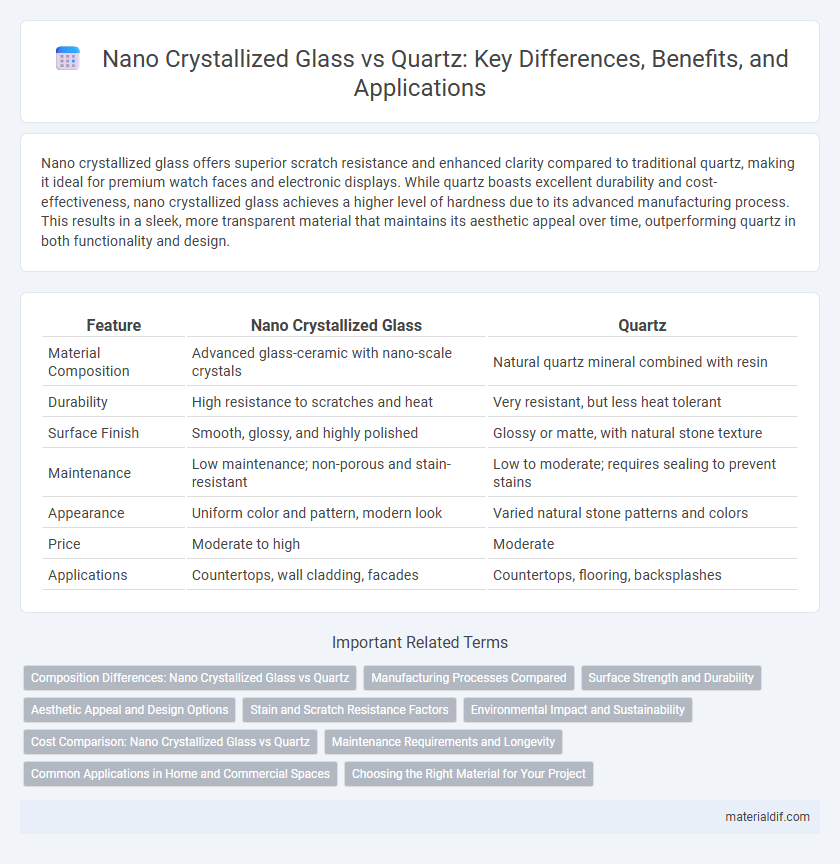

Table of Comparison

| Feature | Nano Crystallized Glass | Quartz |

|---|---|---|

| Material Composition | Advanced glass-ceramic with nano-scale crystals | Natural quartz mineral combined with resin |

| Durability | High resistance to scratches and heat | Very resistant, but less heat tolerant |

| Surface Finish | Smooth, glossy, and highly polished | Glossy or matte, with natural stone texture |

| Maintenance | Low maintenance; non-porous and stain-resistant | Low to moderate; requires sealing to prevent stains |

| Appearance | Uniform color and pattern, modern look | Varied natural stone patterns and colors |

| Price | Moderate to high | Moderate |

| Applications | Countertops, wall cladding, facades | Countertops, flooring, backsplashes |

Composition Differences: Nano Crystallized Glass vs Quartz

Nano crystallized glass consists of a hybrid structure combining glass with nanometer-sized crystals, resulting in enhanced hardness and scratch resistance. Quartz is a natural, crystalline mineral primarily composed of silicon dioxide (SiO2) with a well-ordered atomic arrangement. The key composition difference lies in nano crystallized glass's engineered nanoscale crystals embedded in an amorphous glass matrix, whereas quartz is purely crystalline without an amorphous phase.

Manufacturing Processes Compared

Nano crystallized glass is produced through a high-temperature controlled crystallization process that transforms glass into a durable, scratch-resistant material with enhanced transparency. Quartz manufacturing involves the precise cutting and polishing of natural or engineered quartz slabs, relying on minimal heat treatment but extensive mechanical processing to achieve desired shapes and finishes. The nano crystallization method offers superior structural uniformity and thermal stability compared to the conventional quartz fabrication process.

Surface Strength and Durability

Nano crystallized glass offers superior surface strength compared to traditional quartz due to its advanced manufacturing process that creates a highly dense and uniform microstructure. This results in enhanced resistance to scratches, impacts, and daily wear, making nano crystallized glass more durable for long-term use. Quartz surfaces, while robust, typically exhibit lower hardness and are more prone to microfractures under stress, reducing their overall lifespan in high-traffic applications.

Aesthetic Appeal and Design Options

Nano crystallized glass offers a sleek, modern aesthetic with a smooth, reflective surface that enhances light play and color depth, making it ideal for contemporary design applications. Quartz, known for its natural veining and wide range of colors, provides versatile design options that cater to both classic and modern interior styles. The choice between nano crystallized glass and quartz depends on the desired balance between high-gloss elegance and organic texture in aesthetic appeal.

Stain and Scratch Resistance Factors

Nano crystallized glass exhibits superior stain and scratch resistance compared to traditional quartz surfaces due to its dense, non-porous structure and enhanced hardness. Quartz, while durable, can sometimes be more susceptible to staining from acidic substances and minor scratches over time. The advanced nano crystallization process creates a surface that better withstands daily wear, making it ideal for high-traffic or heavily used areas.

Environmental Impact and Sustainability

Nano crystallized glass offers enhanced durability and recyclability compared to traditional quartz, reducing waste and extending product lifespan. Quartz mining involves significant energy consumption and habitat disruption, whereas nano crystallized glass production utilizes recycled materials and lower-energy processes. Sustainable manufacturing of nano crystallized glass supports eco-friendly construction practices by minimizing carbon footprint and resource depletion.

Cost Comparison: Nano Crystallized Glass vs Quartz

Nano crystallized glass generally costs more than quartz due to its advanced manufacturing process and enhanced durability. Quartz tends to be more budget-friendly, making it a popular choice for affordable countertops and surfaces. While nano crystallized glass offers superior scratch resistance and longevity, its higher price point can impact overall project costs compared to quartz.

Maintenance Requirements and Longevity

Nano Crystallized Glass offers superior resistance to scratches and staining compared to traditional quartz, reducing the need for frequent maintenance and polishing. Quartz surfaces require regular sealing to maintain their durability and appearance, whereas nano crystallized glass remains non-porous and stain-resistant without additional treatments. The longevity of nano crystallized glass often surpasses quartz due to its enhanced hardness and resilience against wear.

Common Applications in Home and Commercial Spaces

Nano crystallized glass and quartz both serve as durable surfaces commonly used in home and commercial spaces for countertops, flooring, and wall cladding. Quartz is favored for kitchen countertops due to its non-porous, stain-resistant properties and wide color range, making it ideal for high-traffic areas. Nano crystallized glass offers superior scratch resistance and a sleek, reflective finish, often selected for commercial spaces requiring modern aesthetics and easy maintenance.

Choosing the Right Material for Your Project

Nano crystallized glass offers exceptional hardness and scratch resistance, making it ideal for high-durability applications, while quartz provides natural beauty with effective heat resistance and low porosity. Quartz surfaces feature consistent patterns and color variations due to engineered minerals, enhancing design flexibility, whereas nano crystallized glass boasts superior chemical stability and stain resistance. Selecting the right material depends on project requirements such as aesthetic preference, durability, maintenance needs, and budget constraints.

Nano Crystallized Glass vs Quartz Infographic

materialdif.com

materialdif.com