Lump quartz consists of large, irregular chunks often used in industrial processes requiring high-purity silica, while granular quartz is composed of small, uniform granules ideal for applications needing consistent particle size and better flowability. The choice between lump and granular quartz depends on the specific requirements of the manufacturing process, such as melting properties or filtration efficiency. Granular quartz typically offers better surface area control, making it preferred in casting, while lump quartz is favored for refractory uses.

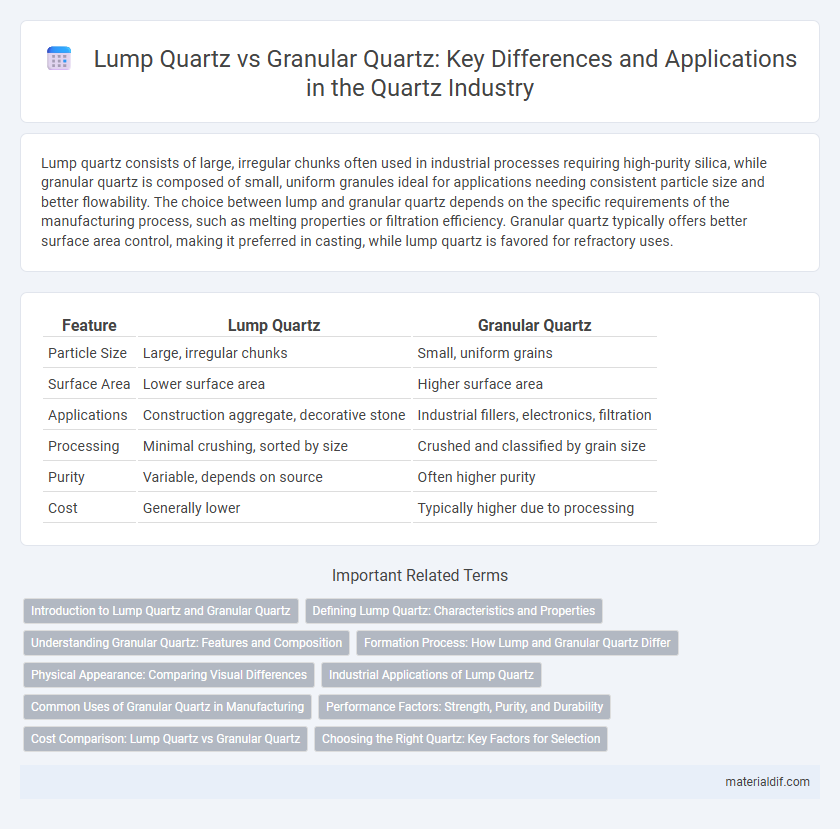

Table of Comparison

| Feature | Lump Quartz | Granular Quartz |

|---|---|---|

| Particle Size | Large, irregular chunks | Small, uniform grains |

| Surface Area | Lower surface area | Higher surface area |

| Applications | Construction aggregate, decorative stone | Industrial fillers, electronics, filtration |

| Processing | Minimal crushing, sorted by size | Crushed and classified by grain size |

| Purity | Variable, depends on source | Often higher purity |

| Cost | Generally lower | Typically higher due to processing |

Introduction to Lump Quartz and Granular Quartz

Lump quartz consists of larger, irregularly shaped quartz pieces often used in industrial applications requiring high purity and durability. Granular quartz features smaller, uniformly sized grains ideal for precision tasks such as filtration and chemical manufacturing. Both forms exhibit high silica content, making them essential in industries demanding consistent quartz quality.

Defining Lump Quartz: Characteristics and Properties

Lump quartz consists of large, irregularly shaped pieces of high-purity silica (SiO2) with a crystalline structure, typically ranging from a few millimeters to several centimeters in size. It exhibits excellent hardness, chemical stability, and thermal resistance, making it ideal for industrial applications such as glass manufacturing and electronics. The physical properties of lump quartz include high density, low impurity content, and translucence, distinguishing it from granular quartz, which is smaller and more uniform in particle size.

Understanding Granular Quartz: Features and Composition

Granular quartz consists of small, uniformly sized particles that offer high purity and enhanced surface area, making it ideal for applications in filtration, ceramics, and electronics. Its granular structure provides excellent thermal stability and chemical resistance, distinguishing it from lump quartz, which features larger, irregular chunks suited for different industrial purposes. Understanding the physical properties and composition of granular quartz helps optimize its use in manufacturing processes requiring precise particle size and purity levels.

Formation Process: How Lump and Granular Quartz Differ

Lump quartz forms through the slow cooling and crystallization of silica-rich fluids, resulting in large, solid masses with a dense, compact structure. Granular quartz develops from the accumulation and cementation of fine quartz grains, typically in sedimentary environments, leading to a porous and granular texture. The formation process directly influences physical properties such as hardness, porosity, and surface area, distinguishing lump quartz's solid mass from granular quartz's aggregate form.

Physical Appearance: Comparing Visual Differences

Lump quartz typically appears as irregular, chunky masses with rough, jagged edges, showcasing a more natural and raw aesthetic. Granular quartz, in contrast, consists of small, uniform grains that create a granular texture and a finer, sandy appearance. These visual differences make lump quartz ideal for decorative, crystalline displays, while granular quartz suits applications requiring smooth, consistent textures.

Industrial Applications of Lump Quartz

Lump quartz offers superior purity and larger crystal size essential for high-quality refractory materials in steel manufacturing and glass production. Its consistent chemical composition makes it ideal for semiconductor and photovoltaic industries, ensuring optimal performance and durability. Unlike granular quartz, lump quartz minimizes contamination, enhancing efficiency in metallurgical processes and electronics fabrication.

Common Uses of Granular Quartz in Manufacturing

Granular quartz is extensively used in the manufacturing industry due to its high purity and uniform particle size, making it ideal for producing glass, ceramics, and silicon-based components. Its consistent granulation enhances the efficiency of industrial processes such as casting and molding, where precise material composition is crucial. Manufacturers also rely on granular quartz for abrasive applications and as a key ingredient in electronics and optical devices.

Performance Factors: Strength, Purity, and Durability

Lump quartz exhibits superior strength and durability due to its larger, more cohesive crystal structure, making it ideal for heavy-duty industrial applications. Granular quartz offers higher purity levels but tends to have lower mechanical strength, which can impact its performance in high-stress environments. The choice between lump and granular quartz depends on the required balance between durability and purity for specific performance needs.

Cost Comparison: Lump Quartz vs Granular Quartz

Lump quartz generally costs more than granular quartz due to its larger, irregular chunks requiring less processing and offering higher purity levels. Granular quartz, being finely crushed and more uniform, is often more economical for bulk applications such as construction and manufacturing. Price variations also depend on quality, source, and intended use, with lump quartz favored in high-end industrial processes where purity and size matter most.

Choosing the Right Quartz: Key Factors for Selection

Lump quartz consists of large, solid pieces ideal for industrial applications requiring high durability, while granular quartz features smaller, uniform grains preferred for precision in manufacturing and filtration processes. Key factors in choosing the right quartz include purity level, particle size distribution, and intended use, as these impact performance and product quality. Understanding these parameters ensures optimal selection for specific applications such as glassmaking, electronics, or abrasives.

Lump Quartz vs Granular Quartz Infographic

materialdif.com

materialdif.com