Hard-paste porcelain is fired at higher temperatures, resulting in a denser, more durable material with greater resistance to chipping and heat. Soft-paste porcelain, created at lower firing temperatures, tends to be softer and more porous, often exhibiting a slightly translucent quality but less durability. Differences in composition, such as the use of kaolin and petuntse in hard-paste versus mixtures of clay and glass frit in soft-paste, impact the physical properties and overall quality of the porcelain.

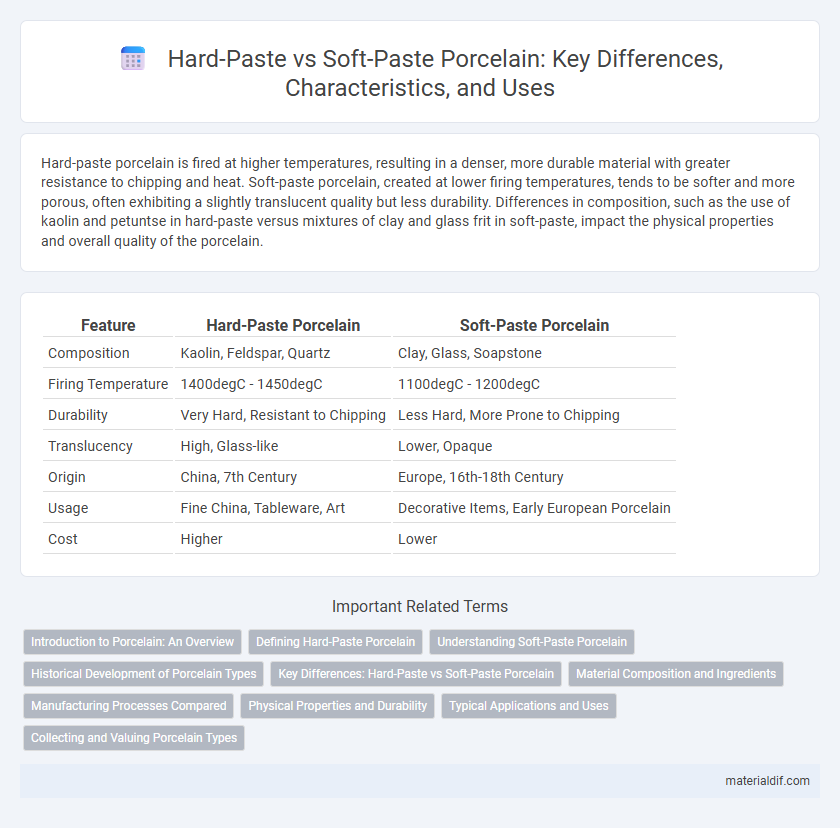

Table of Comparison

| Feature | Hard-Paste Porcelain | Soft-Paste Porcelain |

|---|---|---|

| Composition | Kaolin, Feldspar, Quartz | Clay, Glass, Soapstone |

| Firing Temperature | 1400degC - 1450degC | 1100degC - 1200degC |

| Durability | Very Hard, Resistant to Chipping | Less Hard, More Prone to Chipping |

| Translucency | High, Glass-like | Lower, Opaque |

| Origin | China, 7th Century | Europe, 16th-18th Century |

| Usage | Fine China, Tableware, Art | Decorative Items, Early European Porcelain |

| Cost | Higher | Lower |

Introduction to Porcelain: An Overview

Hard-paste porcelain, made from a mixture of kaolin and petuntse, is known for its durability, high firing temperature, and translucent quality, originating from China's ancient ceramic traditions. Soft-paste porcelain, developed in Europe as an attempt to replicate hard-paste porcelain before kaolin sources were discovered, typically contains a combination of white clay and glassy substances, resulting in a more porous and less heat-resistant material. Both types significantly influenced porcelain production techniques and artistic expression, with hard-paste being prized for its strength and whiteness, and soft-paste for its delicate appearance and ease of shaping.

Defining Hard-Paste Porcelain

Hard-paste porcelain, also known as true porcelain, is defined by its composition of kaolin and petuntse, which are fired at extremely high temperatures around 1,400degC (2,552degF). This firing process results in a dense, vitrified ceramic that is highly durable, non-porous, and resistant to thermal shock. Unlike soft-paste porcelain, hard-paste porcelain exhibits a translucent white surface with superior strength and chip resistance, making it ideal for fine china and technical ceramics.

Understanding Soft-Paste Porcelain

Soft-paste porcelain is characterized by its lower firing temperature and the use of a mixture of clay and glassy substances, such as frit, instead of kaolin, resulting in a more porous and less durable body compared to hard-paste porcelain. This type of porcelain often exhibits a warmer, creamier color and a slightly softer texture, making it more prone to chips and cracks but prized for its delicate appearance. Understanding soft-paste porcelain is essential for collectors and historians as it reflects early European attempts to replicate Chinese hard-paste porcelain before kaolin deposits were discovered outside Asia.

Historical Development of Porcelain Types

Hard-paste porcelain, first developed in 18th-century China and later replicated in Europe, is characterized by its high firing temperature and use of kaolin and petuntse, resulting in superior durability and translucency. Soft-paste porcelain emerged in early 18th-century Europe as an attempt to imitate Chinese hard-paste porcelain before kaolin was discovered, using mixtures of white clay and glassy substances that fired at lower temperatures but produced a softer, less durable material. The historical development of porcelain types reflects technological advancements and resource availability, with hard-paste porcelain eventually becoming the European standard due to its enhanced strength and aesthetic qualities.

Key Differences: Hard-Paste vs Soft-Paste Porcelain

Hard-paste porcelain, originally developed in China, is composed of kaolin and petuntse and fired at higher temperatures around 1400degC, resulting in a denser, more durable, and vitrified material. Soft-paste porcelain, created in Europe to imitate hard-paste porcelain before kaolin deposits were discovered, contains mixtures like glass, bone ash, or white clay and is fired at lower temperatures, producing a softer, more porous, and less translucent body. Key differences include firing temperature, material composition, hardness, translucency, and resistance to thermal shock, with hard-paste porcelain generally exhibiting superior strength and durability.

Material Composition and Ingredients

Hard-paste porcelain primarily consists of kaolin, feldspar, and quartz, creating a vitrified, durable material fired at very high temperatures above 1,300degC. Soft-paste porcelain typically blends white clay with glassy substances like frit, bone ash, or soapstone, resulting in a more porous, less heat-resistant ceramic fired at lower temperatures around 1,100degC. Differences in mineral composition and firing temperatures significantly impact the hardness, translucency, and durability of these two porcelain types.

Manufacturing Processes Compared

Hard-paste porcelain is manufactured by firing a mixture of kaolin and petuntse at extremely high temperatures around 1400degC, resulting in a dense, vitrified ceramic with high durability and translucency. Soft-paste porcelain, on the other hand, is created using a combination of clay and glassy substances like white frit or bone ash, fired at lower temperatures near 1100-1200degC, producing a more porous and less hard material. The distinct firing temperatures and raw material compositions significantly influence the strength, translucency, and overall quality of the final porcelain products.

Physical Properties and Durability

Hard-paste porcelain is characterized by its high density and vitrification, resulting in superior hardness, resistance to scratching, and enhanced durability compared to soft-paste porcelain. Soft-paste porcelain typically contains a mixture of clay and glassy substances, making it more porous and prone to chipping or cracking under thermal stress. The superior physical properties of hard-paste porcelain make it ideal for functional ware requiring long-lasting strength and resistance to mechanical wear.

Typical Applications and Uses

Hard-paste porcelain, known for its durability and high firing temperature, is commonly used in fine tableware, laboratory equipment, and industrial ceramics requiring strength and resistance to thermal shock. Soft-paste porcelain, with its lower firing temperature and softer texture, is typically utilized for decorative objects, ornamental items, and antique-style pottery where delicate detail and aesthetic appeal are prioritized. Both types serve distinct markets, with hard-paste preferred in practical, high-performance applications and soft-paste favored for artistic and collectible pieces.

Collecting and Valuing Porcelain Types

Hard-paste porcelain, prized for its durability and translucency, is typically more valuable to collectors due to its origin in traditional Asian and European manufactories such as Meissen and Jingdezhen. Soft-paste porcelain, often characterized by a softer texture and less resistance to wear, holds significant appeal among collectors for its unique glazes and historical European origins, notably from Sevres and Worcester. Valuing porcelain types requires careful assessment of provenance, manufacturing technique, age, and condition to distinguish authentic hard-paste from soft-paste pieces accurately.

Hard-paste porcelain vs Soft-paste porcelain Infographic

materialdif.com

materialdif.com