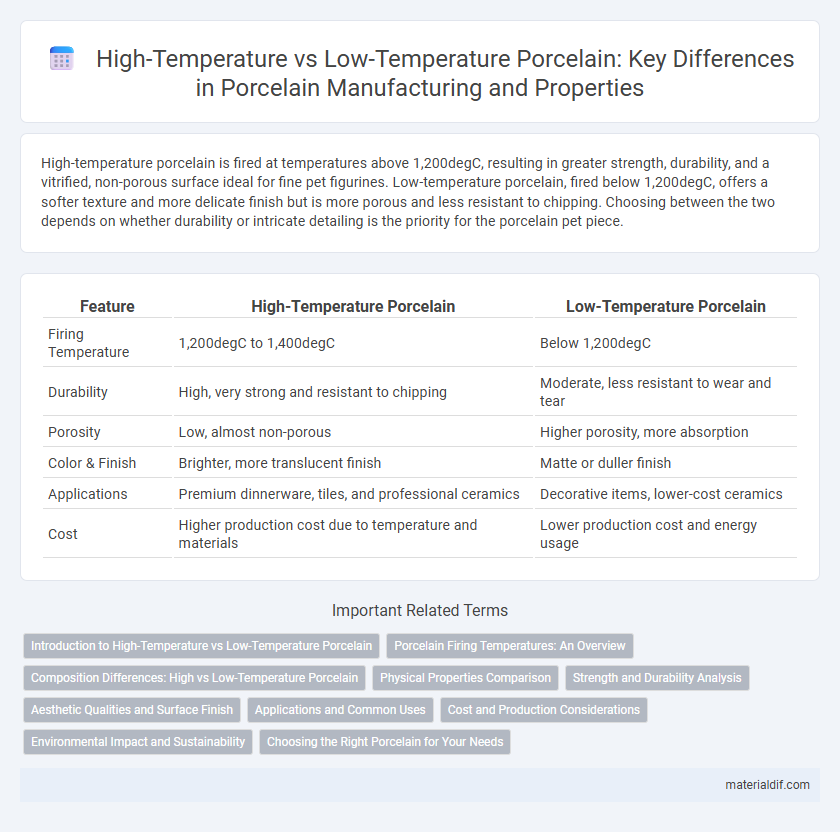

High-temperature porcelain is fired at temperatures above 1,200degC, resulting in greater strength, durability, and a vitrified, non-porous surface ideal for fine pet figurines. Low-temperature porcelain, fired below 1,200degC, offers a softer texture and more delicate finish but is more porous and less resistant to chipping. Choosing between the two depends on whether durability or intricate detailing is the priority for the porcelain pet piece.

Table of Comparison

| Feature | High-Temperature Porcelain | Low-Temperature Porcelain |

|---|---|---|

| Firing Temperature | 1,200degC to 1,400degC | Below 1,200degC |

| Durability | High, very strong and resistant to chipping | Moderate, less resistant to wear and tear |

| Porosity | Low, almost non-porous | Higher porosity, more absorption |

| Color & Finish | Brighter, more translucent finish | Matte or duller finish |

| Applications | Premium dinnerware, tiles, and professional ceramics | Decorative items, lower-cost ceramics |

| Cost | Higher production cost due to temperature and materials | Lower production cost and energy usage |

Introduction to High-Temperature vs Low-Temperature Porcelain

High-temperature porcelain, fired above 1300degC, offers superior strength, durability, and resistance to thermal shock, making it ideal for industrial applications and fine china. Low-temperature porcelain, fired between 1100degC and 1200degC, is more porous and less durable but allows for brighter glazes and more vibrant colors, commonly used in decorative ceramics and art pieces. The firing temperature significantly influences the porcelain's physical properties, translucency, and suitability for various uses.

Porcelain Firing Temperatures: An Overview

High-temperature porcelain is fired at temperatures ranging from 1,200degC to 1,450degC, resulting in a dense, vitrified body with enhanced strength and translucency, making it ideal for fine china and industrial applications requiring durability. Low-temperature porcelain, typically fired between 850degC and 1,100degC, produces a more porous and less vitrified material, often used for decorative items and products where thermal resistance is less critical. The firing temperature directly influences the porcelain's physical properties, including hardness, porosity, and translucency, making it a critical factor in selecting porcelain types for specific uses.

Composition Differences: High vs Low-Temperature Porcelain

High-temperature porcelain is primarily composed of kaolin, feldspar, and quartz, firing at temperatures above 1,200degC, resulting in a dense, vitrified body with high mechanical strength and translucency. Low-temperature porcelain contains a higher percentage of feldspar and glassy fluxes, firing between 1,000degC and 1,150degC, producing a more porous and less durable material compared to high-temperature porcelain. The key compositional difference lies in the flux content and firing temperature, which influence the porcelain's hardness, translucency, and resistance to thermal shock.

Physical Properties Comparison

High-temperature porcelain exhibits superior mechanical strength, higher resistance to thermal shock, and greater durability due to firing temperatures above 1300degC, resulting in a denser and more vitrified microstructure. Low-temperature porcelain, fired typically between 1100degC and 1250degC, has a more porous structure with lower mechanical strength and reduced resistance to heat, making it less suitable for demanding industrial applications. The increased hardness and reduced water absorption of high-temperature porcelain enhance its performance in both domestic and technical settings.

Strength and Durability Analysis

High-temperature porcelain, fired at temperatures above 1300degC, exhibits superior strength and enhanced durability due to its dense vitrified structure, making it highly resistant to mechanical stress and thermal shock. In contrast, low-temperature porcelain, typically fired between 1000degC and 1200degC, tends to have a more porous microstructure, resulting in lower mechanical strength and reduced resistance to wear and fracture. This difference in firing temperature critically influences the material's performance in demanding applications such as electrical insulators, fine china, and industrial ceramics.

Aesthetic Qualities and Surface Finish

High-temperature porcelain exhibits superior aesthetic qualities, characterized by a smooth, glass-like surface finish with enhanced translucency and vibrant glaze stability. Low-temperature porcelain often features a softer, matte finish with less pronounced luster and may show slight imperfections due to lower firing temperatures. The choice between them impacts durability and visual appeal, with high-temperature firing producing a more refined and resilient surface ideal for decorative applications.

Applications and Common Uses

High-temperature porcelain, fired at approximately 1,300degC, is highly durable and resistant to chemical corrosion, making it ideal for industrial insulators, laboratory equipment, and high-voltage electrical components. Low-temperature porcelain, sintered around 1,100degC, is more porous and suits ornamental ceramics, decorative tiles, and dishes where aesthetic appeal is prioritized over extreme strength. The choice between high-temperature and low-temperature porcelain depends on balancing mechanical strength, thermal stability, and design requirements in specific applications.

Cost and Production Considerations

High-temperature porcelain, fired at temperatures above 1300degC, offers superior strength and durability but incurs higher production costs due to extended kiln times and energy consumption. Low-temperature porcelain, fired between 1100degC and 1250degC, reduces fuel usage and shortens firing cycles, resulting in lower manufacturing expenses but typically compromises on mechanical strength and wear resistance. Manufacturers balance these cost and production considerations based on application requirements and budget constraints.

Environmental Impact and Sustainability

High-temperature porcelain is fired at temperatures above 1,200degC, resulting in greater durability and reduced porosity, which enhances its longevity and reduces waste over time. Low-temperature porcelain, fired between 1,000degC and 1,150degC, typically consumes less energy but may be less durable, potentially increasing the frequency of replacement and environmental burden. Sustainable porcelain production prioritizes energy-efficient kilns and raw materials with low environmental footprints, favoring high-temperature porcelain for its longer lifecycle despite higher initial energy use.

Choosing the Right Porcelain for Your Needs

High-temperature porcelain, fired at temperatures above 1200degC, offers superior durability, strength, and resistance to thermal shock, making it ideal for industrial applications and fine dinnerware. Low-temperature porcelain, fired between 1000degC and 1200degC, provides more vibrant colors and intricate designs but has reduced strength and slower wear resistance. Selecting the right porcelain depends on balancing the need for durability against aesthetics and intended use, with high-temperature porcelain favored for functional items and low-temperature porcelain preferred for decorative pieces.

High-Temperature Porcelain vs Low-Temperature Porcelain Infographic

materialdif.com

materialdif.com