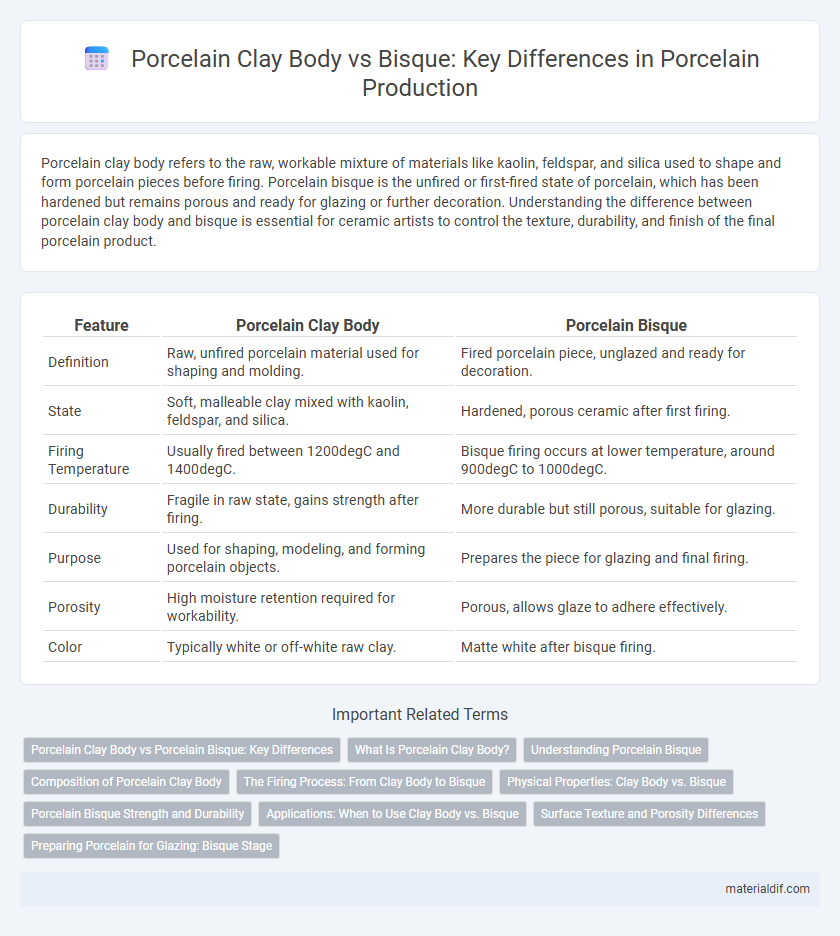

Porcelain clay body refers to the raw, workable mixture of materials like kaolin, feldspar, and silica used to shape and form porcelain pieces before firing. Porcelain bisque is the unfired or first-fired state of porcelain, which has been hardened but remains porous and ready for glazing or further decoration. Understanding the difference between porcelain clay body and bisque is essential for ceramic artists to control the texture, durability, and finish of the final porcelain product.

Table of Comparison

| Feature | Porcelain Clay Body | Porcelain Bisque |

|---|---|---|

| Definition | Raw, unfired porcelain material used for shaping and molding. | Fired porcelain piece, unglazed and ready for decoration. |

| State | Soft, malleable clay mixed with kaolin, feldspar, and silica. | Hardened, porous ceramic after first firing. |

| Firing Temperature | Usually fired between 1200degC and 1400degC. | Bisque firing occurs at lower temperature, around 900degC to 1000degC. |

| Durability | Fragile in raw state, gains strength after firing. | More durable but still porous, suitable for glazing. |

| Purpose | Used for shaping, modeling, and forming porcelain objects. | Prepares the piece for glazing and final firing. |

| Porosity | High moisture retention required for workability. | Porous, allows glaze to adhere effectively. |

| Color | Typically white or off-white raw clay. | Matte white after bisque firing. |

Porcelain Clay Body vs Porcelain Bisque: Key Differences

Porcelain clay body refers to the unfired, malleable mixture of kaolin, feldspar, and quartz used to shape porcelain items, while porcelain bisque is the fired, unglazed form that has undergone a first kiln firing to become hard and durable. Key differences include the physical state--clay body is soft and moldable, bisque is solid and porous--and the purpose, where clay body is for shaping, and bisque serves as the base for glazing and further firing. Understanding these distinctions is crucial for ceramic artists in controlling the texture, strength, and finishing processes of porcelain products.

What Is Porcelain Clay Body?

Porcelain clay body is a refined, highly plastic mixture of kaolin, feldspar, and silica designed for shaping and forming pottery before firing. It provides a smooth, white, and translucent quality after firing, making it prized for its strength and delicate appearance. Unlike porcelain bisque, which refers to fired, unglazed porcelain ware, porcelain clay body is the unfired raw material ready for molding and sculpting.

Understanding Porcelain Bisque

Porcelain bisque refers to porcelain clay that has undergone the first firing, known as bisque firing, which removes moisture and organic materials, leaving the piece porous and ready for glazing or decorating. Unlike porcelain clay bodies in their unfired, plastic state, bisque porcelain is more fragile and lighter in color, showcasing a matte surface ideal for detailed painting or glazing techniques. Understanding porcelain bisque is essential for ceramic artists aiming to achieve precise finishes and durable final products in porcelain works.

Composition of Porcelain Clay Body

Porcelain clay body primarily consists of kaolin, feldspar, and quartz, creating a fine, white, and plastic material ideal for shaping and molding. This composition differs from porcelain bisque, which is the fired, hardened state of the clay body before glazing, exhibiting increased strength but reduced plasticity. The balanced mix of minerals in the clay body ensures vitrification at high temperatures, resulting in the characteristic translucence and durability of porcelain.

The Firing Process: From Clay Body to Bisque

Porcelain clay body transforms into porcelain bisque through a precise firing process that removes moisture and organic materials, ensuring durability and strength. This initial bisque firing typically occurs at temperatures between 1730degF and 1940degF (945degC to 1060degC), where the clay becomes porous yet stable enough for glazing. The controlled heat treatment alters the molecular structure, setting the foundation for the final vitrification stages that define porcelain's characteristic translucency and hardness.

Physical Properties: Clay Body vs. Bisque

Porcelain clay body is a raw, malleable material composed primarily of kaolin, feldspar, and quartz, known for its plasticity and workability before firing. In contrast, porcelain bisque refers to the unfired or once-fired ceramic that has lost most of its moisture and plasticity, exhibiting increased hardness and fragility. The key physical difference lies in the clay body's flexibility and moisture content versus the bisque's rigidity and porosity after initial firing.

Porcelain Bisque Strength and Durability

Porcelain bisque, fired to a higher temperature than porcelain clay body, exhibits enhanced strength and durability due to its vitrified structure, making it less porous and more resistant to chipping or cracking. This hardness results from the removal of chemically bound water during the bisque firing process, which increases the material's structural integrity compared to the unfired porcelain clay body. Consequently, porcelain bisque is ideal for fine ceramics requiring long-lasting wear and mechanical resilience.

Applications: When to Use Clay Body vs. Bisque

Porcelain clay body is ideal for shaping, sculpting, and wheel-throwing projects that require malleability and precise detailing before firing. Porcelain bisque, being already fired and hardened, is best used for glazing, decorating, or assembling pre-fired pieces without the risk of distortion or shrinkage. Artists and potters choose porcelain clay body for initial forming stages, while bisque porcelain suits finishing processes that demand a stable, porous surface.

Surface Texture and Porosity Differences

Porcelain clay body exhibits a smooth, dense surface texture with low porosity due to its high feldspar and kaolin content, resulting in a vitrified finish after firing. Porcelain bisque, on the other hand, is unglazed and porous, allowing it to absorb glazes effectively before the final firing. This porous bisque texture contrasts with the non-porous, glass-like surface of fired porcelain clay bodies.

Preparing Porcelain for Glazing: Bisque Stage

Porcelain clay body becomes porcelain bisque after undergoing the bisque firing process, which hardens the clay while maintaining its porous nature crucial for absorbing glazes. Preparing porcelain for glazing requires the bisque stage to ensure proper glaze adhesion and prevent defects like blistering or running. Controlling the bisque firing temperature, typically between Bisque firing temperature usually ranges from Cone 04 to Cone 06 (approximately 1828degF to 1945degF), is essential to optimize the balance between porosity and strength in porcelain bisque ware.

Porcelain Clay Body vs Porcelain Bisque Infographic

materialdif.com

materialdif.com