Porcelain firing requires higher temperatures, typically between 1,200degC and 1,400degC, to achieve its characteristic strength, translucency, and vitrification. Earthenware firing occurs at lower temperatures, around 1,000degC to 1,150degC, resulting in a more porous and less durable ceramic. The firing process directly affects the final properties, with porcelain becoming dense and glass-like, while earthenware remains more porous and matte.

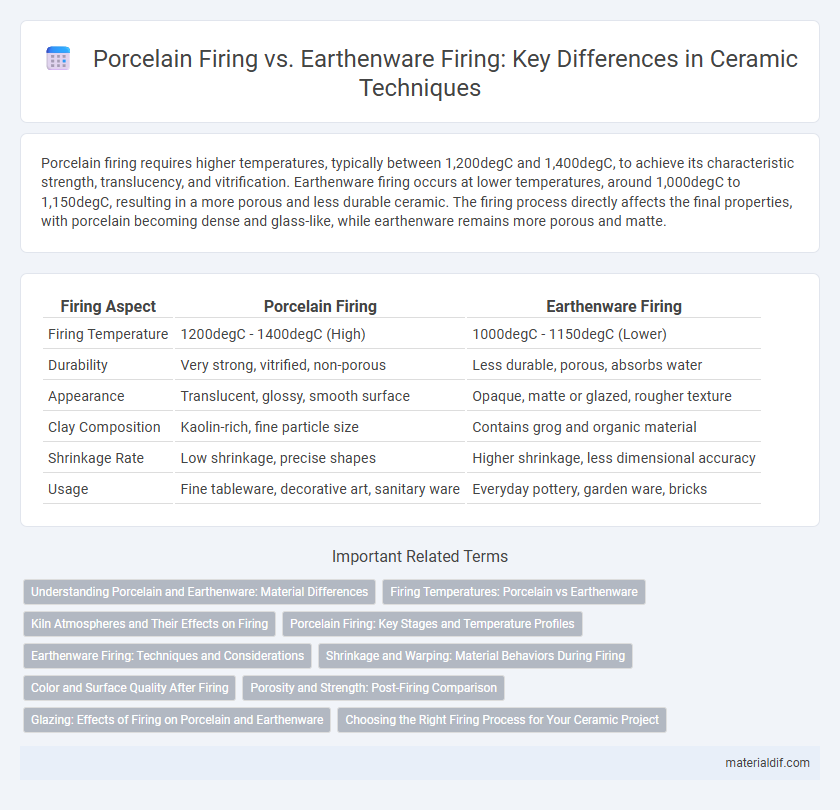

Table of Comparison

| Firing Aspect | Porcelain Firing | Earthenware Firing |

|---|---|---|

| Firing Temperature | 1200degC - 1400degC (High) | 1000degC - 1150degC (Lower) |

| Durability | Very strong, vitrified, non-porous | Less durable, porous, absorbs water |

| Appearance | Translucent, glossy, smooth surface | Opaque, matte or glazed, rougher texture |

| Clay Composition | Kaolin-rich, fine particle size | Contains grog and organic material |

| Shrinkage Rate | Low shrinkage, precise shapes | Higher shrinkage, less dimensional accuracy |

| Usage | Fine tableware, decorative art, sanitary ware | Everyday pottery, garden ware, bricks |

Understanding Porcelain and Earthenware: Material Differences

Porcelain firing occurs at higher temperatures ranging from 1,200degC to 1,400degC, resulting in a dense, vitrified, and translucent ceramic body, whereas earthenware firing occurs at lower temperatures between 1,000degC and 1,150degC, producing a more porous and opaque material. Porcelain is made primarily from kaolin clay, which contributes to its strength and whiteness, while earthenware contains more iron and other impurities that affect color and durability. These material differences influence the final properties and applications of each ceramic type, with porcelain being favored for fine china and earthenware for everyday pottery.

Firing Temperatures: Porcelain vs Earthenware

Porcelain firing temperatures typically range between 1,200degC and 1,400degC, resulting in a vitrified, non-porous, and highly durable final product. Earthenware firing occurs at lower temperatures, usually between 1,000degC and 1,150degC, producing a more porous and less dense ceramic. The higher firing temperature of porcelain allows for greater strength and translucency compared to the more porous earthenware.

Kiln Atmospheres and Their Effects on Firing

Porcelain firing requires a high-temperature kiln atmosphere typically around 1,200-1,400degC with a controlled oxidation environment, promoting vitrification and translucency, whereas earthenware firing occurs at lower temperatures of 1,000-1,150degC often in a more variable atmosphere that affects porosity and color. The oxidation or reduction atmosphere within the kiln influences the final texture and strength; porcelain benefits from stable oxidation to avoid cloudiness, while earthenware often uses reduction to enhance earthy tones and surface effects. Kiln atmosphere control is critical in porcelain firing to achieve its characteristic whiteness and durability, contrasting with the more forgiving and rustic qualities of earthenware firing.

Porcelain Firing: Key Stages and Temperature Profiles

Porcelain firing involves reaching high temperatures typically between 1,200degC and 1,400degC to achieve vitrification and translucency, unlike earthenware which fires at lower ranges around 1,000degC to 1,150degC. The firing process for porcelain includes key stages such as drying, bisque firing at approximately 900degC, and glaze firing at peak temperatures to ensure strength and durability. Precise temperature control and slow cooling during these stages are critical to prevent warping and cracking, making porcelain firing more complex than earthenware firing.

Earthenware Firing: Techniques and Considerations

Earthenware firing typically occurs at lower temperatures ranging from 1,000 to 1,150 degrees Celsius, which allows for a porous and less vitrified ceramic body compared to porcelain. Techniques such as oxidation and reduction atmospheres influence the final color and texture, with the choice of clay and glaze composition being crucial for durability and aesthetic outcome. Proper control of firing schedules, including slow cooldown phases, prevents cracking and warping, ensuring the integrity of earthenware pieces.

Shrinkage and Warping: Material Behaviors During Firing

Porcelain firing requires higher temperatures around 1,200-1,400degC, resulting in less shrinkage and reduced warping due to its fine kaolin clay composition and vitrification process. Earthenware firing occurs at lower temperatures, approximately 1,000-1,150degC, causing greater shrinkage and increased warping from its porous and coarse clay particles. The material behaviors during firing directly affect the final ceramic structural integrity and surface finish, influencing the choice of firing temperature based on desired product durability.

Color and Surface Quality After Firing

Porcelain firing occurs at higher temperatures, typically between 1200degC and 1400degC, resulting in a vitrified, glass-like surface with a smooth, translucent white appearance. Earthenware firing, conducted at lower temperatures around 1000degC to 1150degC, produces a more porous and opaque surface with a coarser texture and earthy tones ranging from reds to browns. The high firing temperature of porcelain enhances its durability and color purity, while earthenware's lower firing temperature retains more surface texture and natural iron-rich coloration.

Porosity and Strength: Post-Firing Comparison

Porcelain firing occurs at higher temperatures, typically between 1,200degC and 1,400degC, resulting in a vitrified, non-porous surface with enhanced strength and durability. Earthenware firing, conducted at lower temperatures around 1,000degC to 1,150degC, produces a more porous and less dense material prone to water absorption and reduced mechanical strength. The increased vitrification during porcelain firing significantly improves the ceramic's resistance to wear and structural integrity compared to earthenware.

Glazing: Effects of Firing on Porcelain and Earthenware

Porcelain firing involves higher temperatures, typically around 1,200-1,400degC, which vitrifies the body and creates a smooth, glass-like glaze that is durable and translucent. Earthenware firing occurs at lower temperatures, usually between 1,000-1,150degC, resulting in a more porous, matte glaze that is less durable and often requires a glaze to achieve waterproofing. The intense heat in porcelain firing enhances glaze fusion and clarity, whereas earthenware glazing retains more textured, earthy qualities due to its lower firing range.

Choosing the Right Firing Process for Your Ceramic Project

Porcelain firing requires higher temperatures, typically between 1,200degC and 1,400degC, resulting in a dense, vitrified, and translucent finish ideal for fine, durable ceramics. Earthenware firing occurs at lower temperatures, around 1,000degC to 1,150degC, producing porous, less vitrified pottery that often requires glazing for waterproofing. Selecting the right firing process depends on the desired strength, translucency, and functionality of the ceramic piece, with porcelain offering superior durability and a refined aesthetic compared to earthenware.

Porcelain firing vs Earthenware firing Infographic

materialdif.com

materialdif.com